PU Refrigerator & Freezer Production Line

يوريكسيد provides complete production line solutions for foam cabinets of refrigerators, freezers, commercial display cabinets and other refrigeration equipment. It is suitable for new factories or expansion projects, and supports on-demand customization, fast delivery, global on-site installation and commissioning.

The Types of UREXCEED PU Refrigerator Freezer Production Line

The refrigerator and freezer production lines designed and developed by يوريكسيد mainly include ground rail type, mobile type, linear type, rotary type, etc. according to different production lines.

Ground Rail PU Production Line for Refrigerator & Freezer Cabinet Production

This production line is developed for refrigerators, freezers, display cabinets and other box structural components. It consists of a chain drive system, foaming fixture, oven, foaming machine platform, steam heating and exhaust system, filling manipulator, unlocking mechanism, conveying trolley, cover opening and closing guide rail, auxiliary clamping device and supporting pneumatic system, hydraulic system, electronic control system, etc., to achieve efficient, accurate and batch polyurethane PU foaming molding. It can be connected with the whole line flow operation and is widely used in the box filling process of cold chain products such as household refrigerators, supermarket display cabinets, and catering equipment.

Full Auto Circulation

Closed-loop rail system for consistent batch production

Accurate Injection

Multi-point high-pressure injection avoids shrinkage or voids

The Specification of Ground Rail PU Production Line

غرض | Specification |

Overall Dimensions (L×W×H) | Approx. 29,500 × 7,950 × 3,350 mm |

Number of Stations | 26 |

Fixture Template Size | 2,000 × 900 mm |

Mold Closing Height | 200 mm (customizable upon request) |

Production Cycle Time | 20 seconds (excluding manual operation time) |

Heating Method | Steam heating or oil mold temperature controller heating |

Foaming Material | POL + Cyclopentane + ISO, or POL + 141b + ISO |

Injection Method | Manual vertical pouring with mold open |

Steam Capacity | 200 m³/h |

Curing Oven Temperature | 55 ± 5°C |

Steam Temperature | 120–150°C |

Compressed Air Requirement | Working pressure ≥ 0.5 MPa; Air flow approx. 0.1 m³/min |

Power Consumption | – With steam heating: approx. 25 kW (380V, 50Hz) |

Straight-Line PU Production Line for Refrigerator & Freezer Cabinets

The foaming line adopts a linear layout, consisting of a preheating oven, a power roller line, a 90° turning machine for inlet box (including box identification), a two-way transport system (which may include an automatic nitrogen filling device), a foaming fixture, an automatic filling system, an outlet lifting and translation machine, an external mold water heating system, and a supporting pneumatic system and an electronic control system. The fixture has an automatic bubble blocking function, and the mold change adopts a cylinder or a manually driven connecting rod mechanism, which has a dual self-locking function of manual control and electrical control. It is suitable for small and medium-sized production capacity or multi-specification mixed line manufacturing scenarios. The production line has the characteristics of beautiful appearance, compact structure, less environmental pollution, low labor intensity, small footprint, strong functions, high production efficiency, and flexible production of multiple varieties.

Multi-model capability

Supports switchable molds for different cabinet types

High automation

Less labor, better efficiency

The Specification of Straight-Line PU Production Line

غرض | Specification |

Cabinet Size Range | Length: 800–2000 mm; Width: 450–800 mm; Depth: 450–900 mm |

وقت المعالجة | Adjustable within 999 seconds |

Number of Stations | 6–8 |

Injection Method | Single-head horizontal pouring from one end |

Foaming Material | POL + Cyclopentane + ISO, or POL + 141b + ISO |

Production Cycle Time | 30 seconds/unit (depends on number of fixtures and curing time) |

Product Variety | Supports simultaneous production of 6–8 different product sizes |

Fixture Lifting Drive | Motor-driven |

Voltage | 380V, 50Hz |

Total Power of Production Line | Max ≤ 190 kW, External cabinet power: 24V |

Compressed Air Requirement | Working pressure ≥ 0.5 MPa; Air flow approx. 0.1 m³/min |

Rotary PU Production Line for Refrigerator and Freezer Doors

The foaming line is a rotary (hub type) seven (eight) station door foaming equipment, mainly used for refrigerator (cabinet) door foaming. It consists of a main frame, a rotary frame, a foaming mold frame, a hydraulic drive, a positioning, a mold opening and closing system, a material injection and transfer system, a variety identification system, and a supporting hydraulic system, an electric control system, etc. The clamp templates are heated by water. The mold clamping is safe and reliable, and the mold change is convenient and fast, which is suitable for flexible production of multiple varieties. The production line has the characteristics of small footprint, compact structure, and easy operation.

Compact rotary layout

Space-saving design for medium factory floors

Fast cycle times

Efficient for medium-to-high volume production

The Specification of Rotary PU Production Line

غرض | Specification |

Overall Dimensions (L×W×H) | Approx. 000 × 5500 × 4600 mm |

Number of Stations | 7 (8) |

Fixture Template Size (L×W) | 2000 × 900 mm |

Mold Closing Height | 200 mm |

Production Cycle Time | 46 seconds (excluding manual operation time) |

Foaming Material | POL + Cyclopentane + ISO, or POL + 141b + ISO |

Injection Method | Automatic pouring with mold open |

Heating Method | Water heating via mold temperature controller |

Power Requirement | Approx. 65 kW (380V, 50Hz) |

If you want to more details of refrigerator freezer production line

If the above introduction cannot answer your questions, please call us directly +8613656166310 or leave your contact information and needs. We will try our best to contact you as soon as possible to answer your questions.

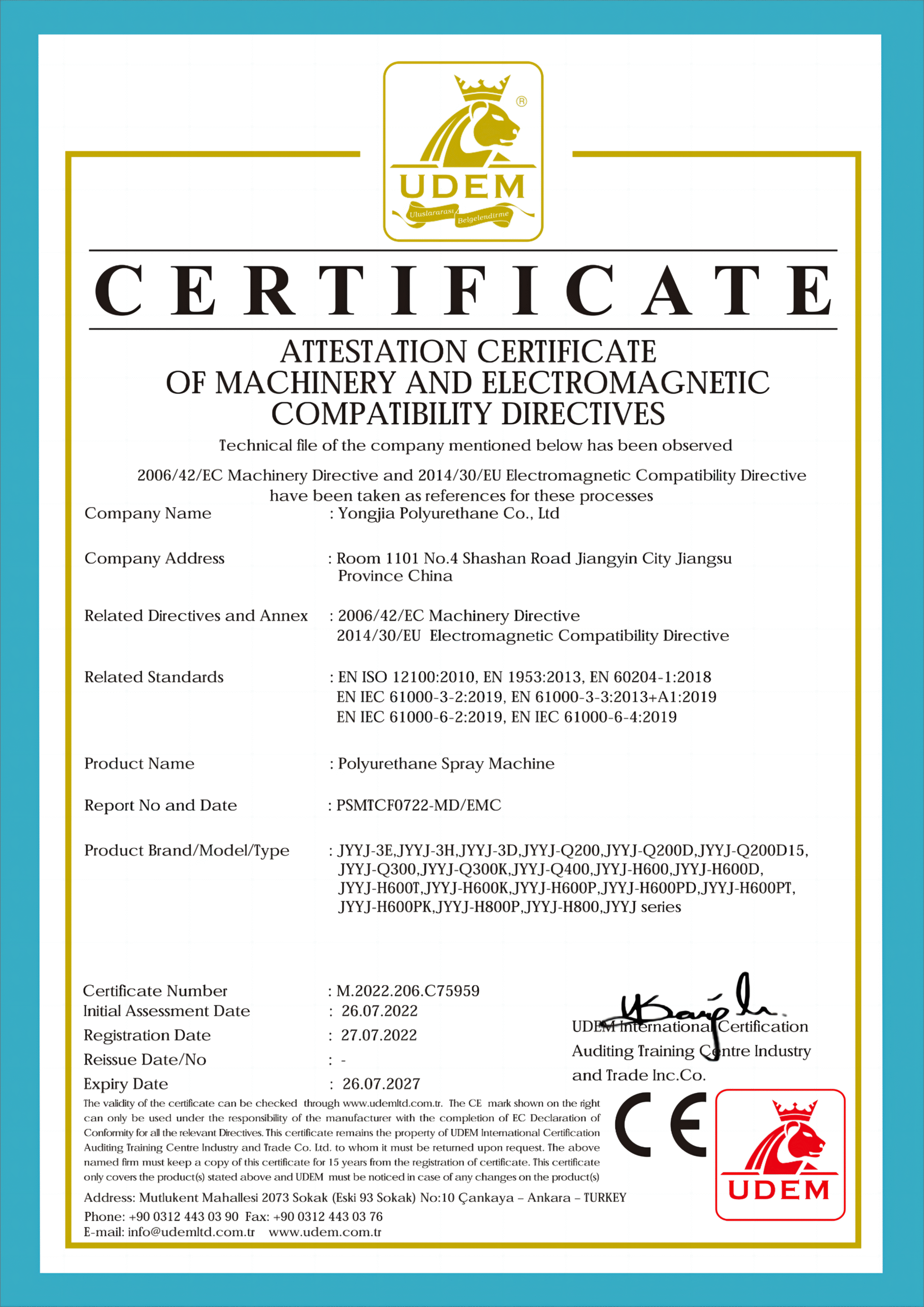

Certifications of

UREXCEED PU Production Line

Why Choose

UREXCEED PU Foam Production Line

Full Machine Customization

For polyurethane foaming machines, customers can freely choose the machine configuration according to their budget. From Siemens PLC to homemade material tanks, يوريكسيد can customize the machine according to customer needs.

Experienced Engineers

We have experienced mechanical engineers. In addition to customizing machines according to customer requirements, يوريكسيد يمكن أن توفر أيضا on-site installation and training services to improve customer learning efficiency and save customer learning time.

One-stop Solution Provider

يوريكسيد can provide a complete set of cold chain production line, from molds to foaming machines to complete assembly lines, to meet all the needs of customers for cold chain production.

24-hour After-sales Serivce

يوريكسيد PU machines have a 1-year warranty and 3-year telephone and video follow-up. يوريكسيد can provide remote diagnosis services for any problems.

Customers of

UREXCEED PU Foam Production Line

UREXCEED has brought high-quality polyurethane foaming machines to customers in more than 100 countries and regions around the world.

FAQ of UREXCEED

PU Foam Production Line

Most frequent questions and answers

Yes, UREXCEED is a polyurethane equipment manufacturer with more than ten years of experience. We have our own design team, engineers and sales team.

Our factory is in Jiangyin, Wuxi, about 2 hours’ drive from Shanghai. You can take the high-speed rail directly from Shanghai to Jiangyin, which only takes 1 hour. We can pick you up at the high-speed rail station.

They work on different principles. One relies on high pressure to mix raw materials, and the other relies on mechanical stirring to mix raw materials. The high-pressure machine mixes more fully, has a wider flow range, and has a self-cleaning function. The low-pressure machine is smaller in size and cheaper in price, and can be used to produce some particularly small foam products.

The weight of the product you need to produce, the product output, your budget and the size of the site, etc.

أحدث أخبار

Of UREXCEED PU Foam Production Line

تلعب صناعة سلسلة التبريد دورًا حاسمًا في ضمان بقاء المنتجات الغذائية والصيدلانية والبيولوجية الصيدلانية عند درجات الحرارة المنخفضة المطلوبة أثناء النقل والتخزين. ومع استمرار ارتفاع الطلب من جانب المستهلكين على سلامة الغذاء وجودة المنتج والاستدامة البيئية، تشهد صناعة سلسلة التبريد نموًا مطردًا، وخاصة في...

في صناعة سلسلة التبريد، تتأثر حصة السوق من مواد العزل الحراري بالعديد من العوامل، بما في ذلك متطلبات الأداء، ومراقبة التكاليف، وسياسات حماية البيئة، ومعايير الصناعة، وما إلى ذلك. لذلك سوف نقدم بالتفصيل حصة السوق من PU و EPS و VIP والصوف المعدني ورغوة PVC و XPS في سلسلة التبريد...

مع التقدم المستمر للعولمة والطلب المتزايد على الأغذية والأدوية عالية الجودة من المستهلكين، تلعب صناعة سلسلة التبريد دورًا متزايد الأهمية في الخدمات اللوجستية العالمية. ولضمان التحكم الدقيق في درجة الحرارة أثناء النقل والتخزين، تعتمد صناعة سلسلة التبريد على مواد عزل عالية الأداء. ومن بين العديد من...