Client Background

Our client is a leading industrial manufacturer based in Iran, specializing in high-performance elastomer products used in various industries such as automotive, electronics, and machinery. To increase production capacity and meet growing market demands, the client decided to invest in a complete elastomer injection molding production line.

Client’s Needs

The client required a complete, efficient, and stable production line capable of producing various elastomer products, especially under high-temperature conditions for precise injection molding. Additionally, the client sought an advanced heating and curing system as well as high-quality molds to ensure optimal product quality and high production output.

Solution Provided

In response to the client’s needs, we provided a full elastomer injection molding production line, including:

- High-Temperature Elastomer Machine: Our equipment is designed to handle high-temperature elastomer materials with precision temperature and pressure control, ensuring no deformation or waste during the molding process.

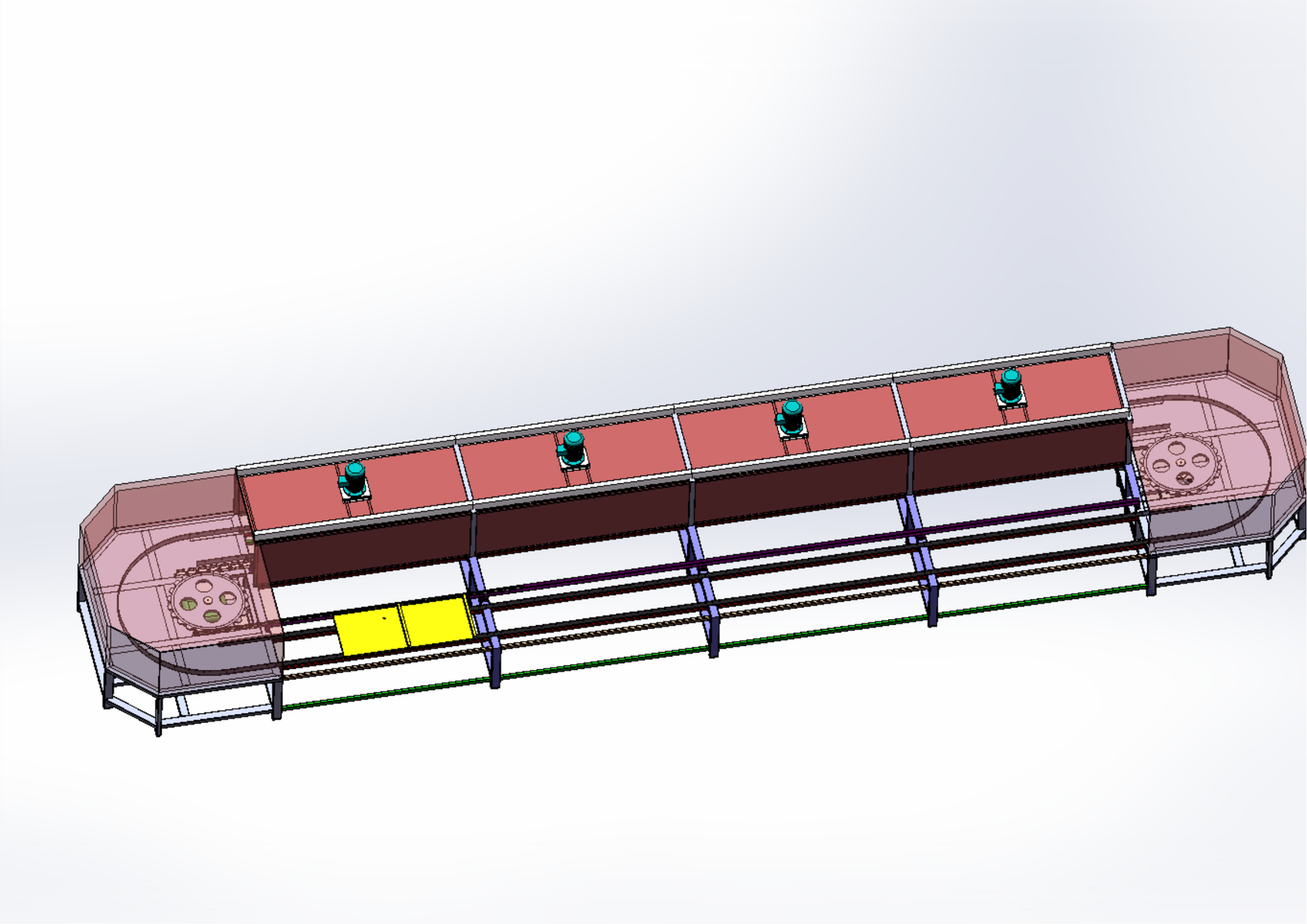

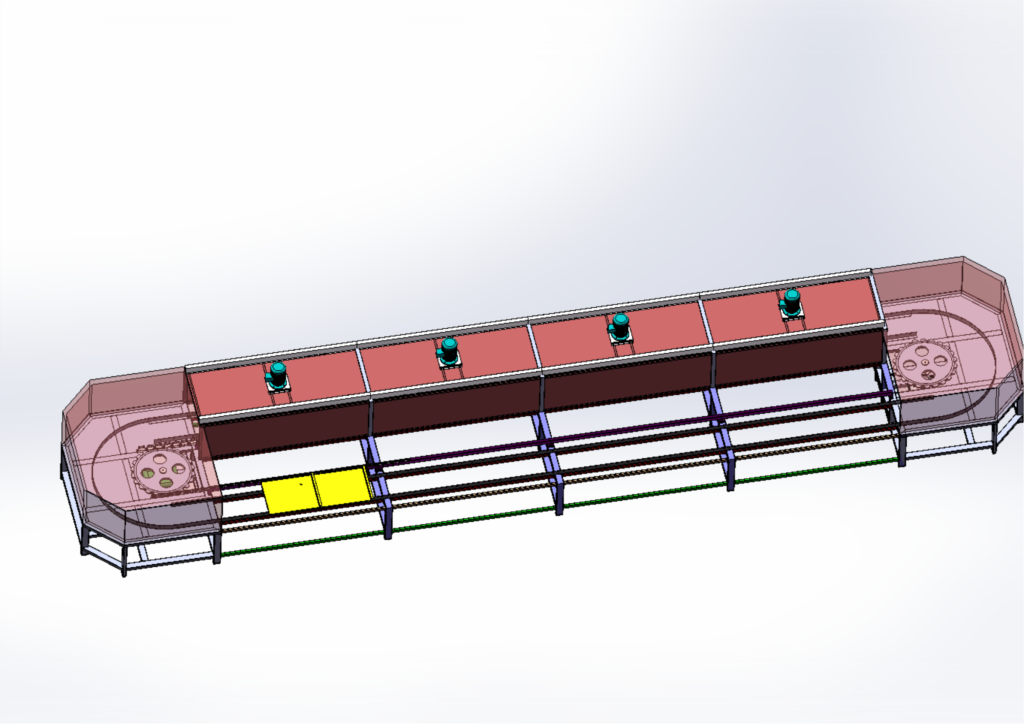

- Oven: The oven we provided ensures uniform heat distribution and precise temperature control, enabling the elastomer products to achieve ideal physical properties during the curing process.

- Produktionslinie: The entire production line is equipped with an advanced automation control system, managing every step from material delivery, injection, curing, to cooling, ensuring precise control, higher efficiency, and reduced human error.

- Molds: We supplied custom-designed molds to meet the client’s specific production requirements. These high-precision molds ensure consistent product dimensions and stable quality.

Advantages of Our Equipment

Our elastomer injection molding production line offers several key advantages that set it apart:

- Supports MDI and TDI Systems: Our equipment is compatible with both MDI and TDI systems, providing flexibility to accommodate different elastomer materials.

- TDI Hot Air Circulation Heating: The TDI hot air circulation heating system ensures even temperature distribution throughout the production process, improving consistency and stability of the molded products.

- Supports Up to 5 Color Paste Systems: The equipment can handle up to five different color paste systems, offering a wide range of color options to meet diverse market demands for elastomer products.

- One-Stop Solution: We provide a comprehensive one-stop solution, including raw materials, cleaning agents, ovens, workstations, and more, simplifying the procurement process for the client.

- Low Noise, Low Power Consumption, and Energy-Efficient: Our equipment is designed to be energy-efficient with low noise and low power consumption, reducing operational costs and minimizing environmental impact.

Results and Feedback

Since the production line was installed, the client has experienced significant improvements in both production efficiency and product quality. The high-temperature elastomer machine and oven work seamlessly together to shorten the production cycle, while the precision molds ensure consistent product quality. The client is particularly satisfied with the increased automation, reduced labor costs, and the high standard of the final products.

The client also appreciated the complete solution we provided, including equipment installation, commissioning, technical support, and training services, ensuring that the production line operates smoothly and that their team can quickly master the production process.

Conclusion

Through this collaboration, the Iranian client successfully achieved automated production, stable product quality, and improved production efficiency. We provided not just equipment, but a comprehensive solution that gave the client a competitive edge in the market.