Hochwertige Produktionslinie für Autositze

Produktionslinie für Autositze

UREXCEED polyurethane automotive seat production line is designed for efficient and high-precision molding of automotive seats, meeting the stringent requirements of modern automotive industries for comfort, safety, and environmental standards. The full production line includes a Schaummaschine, Formen und Formrahmen, integriert mit fortschrittlichen Steuerungssystemen, um die höchsten Qualitätsstandards während des gesamten Produktionsprozesses zu gewährleisten.

Prozessablauf von UREXCEED Produktionslinie für PU-Autositze

Schritt1

Schritt2

Schritt3

Schritt4

Schritt5

Über UREXCEED Produktionslinie für Autositze

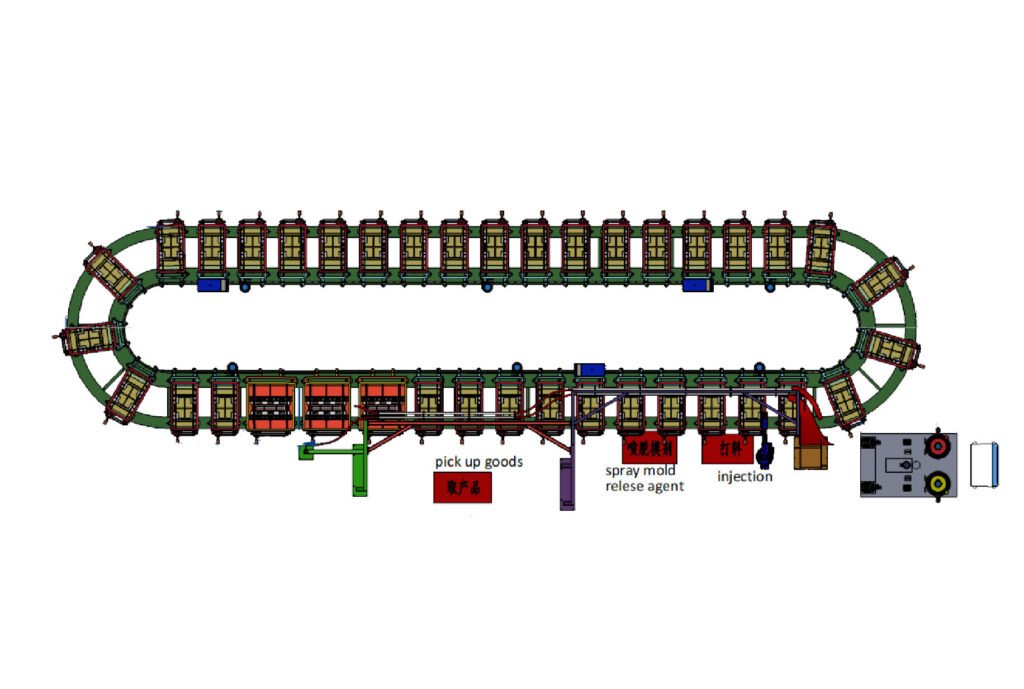

UREXCEED offers a wide range of customizable lines, including rotary lines, carousel lines and banana lines, designed to meet the specific needs of different manufacturing processes. Regardless of the complexity or scale of your production needs, UREXCEED can provide you with the right line to ensure maximum productivity and minimize downtime. Our comprehensive solutions are designed to increase efficiency, reduce operating costs and enhance the overall manufacturing process.

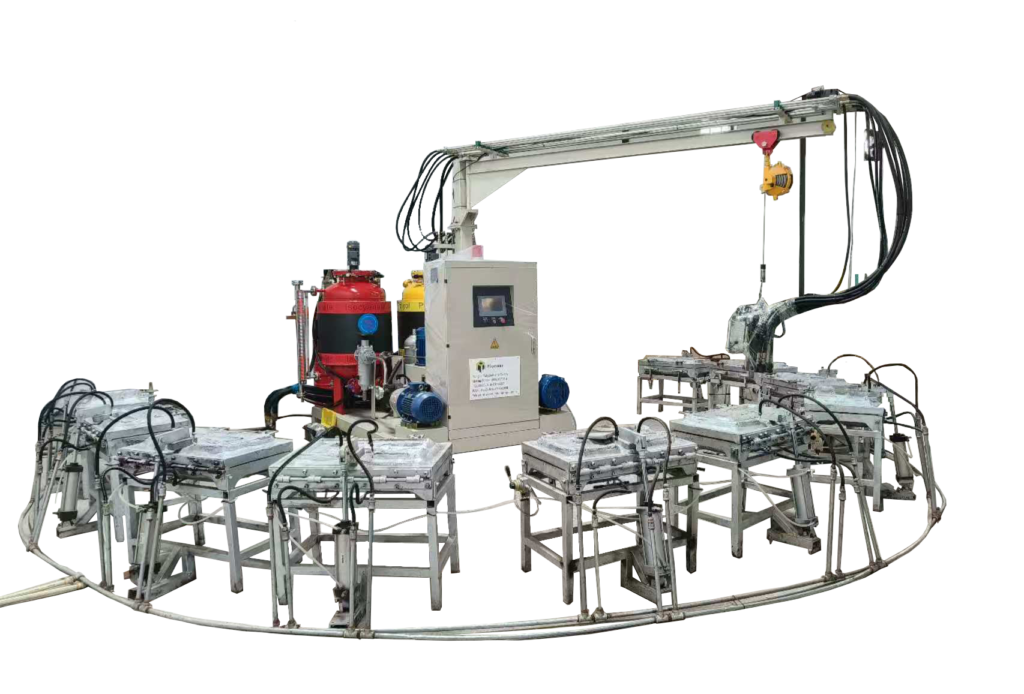

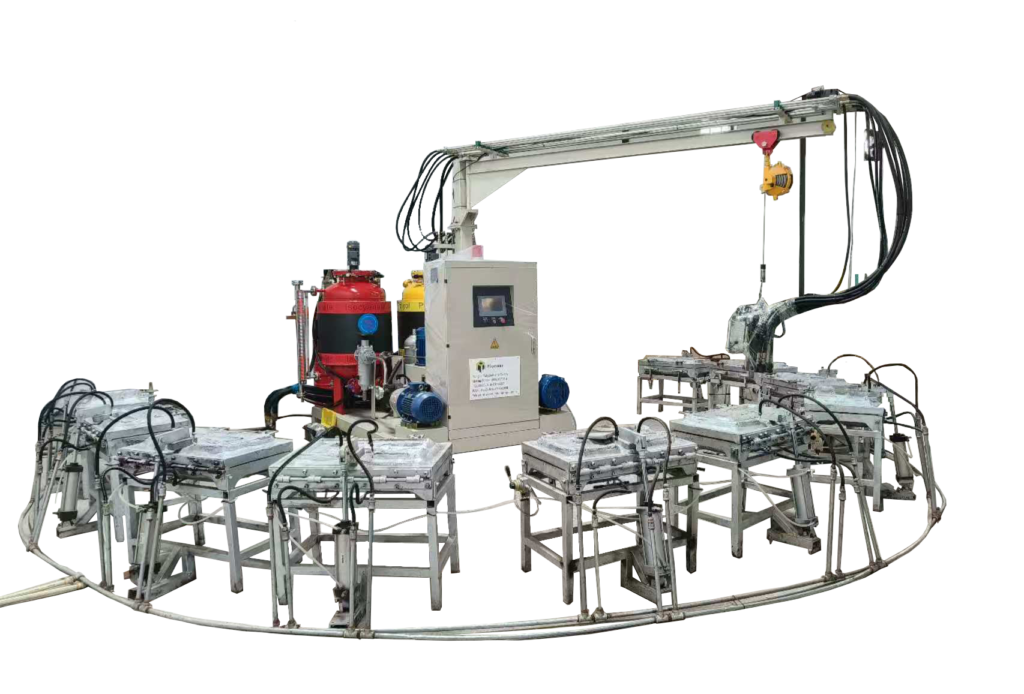

Karussell-Produktionslinie

Am besten für einfache, kurzzyklische Produktion mit unkomplizierter Struktur

Karussell-Produktionslinie

Am besten für einfache, kurzzyklische Produktion mit unkomplizierter Struktur

Anwendungen: Die UREXCEED-Produktionslinie eignet sich für relativ einfache Herstellungsprozesse wie Beschichten, Pressen oder andere Vorgänge. Sie wird häufig für die Produktion kleiner Chargen oder Produkte mit spezifischen Prozessanforderungen verwendet.

Merkmale: Die kompakte und unkomplizierte Karussell-Produktionslinie ist ideal für die Herstellung einzelner Produkte oder kleine Produktionsanforderungen mit kurzen Zyklen.

Rotationsproduktionslinie

Geeignet für die groß angelegte, mehrstufige automatisierte Produktion.

Anwendungen: Rotationsproduktionslinien von UREXCEED werden häufig für Produkte verwendet, die mehrere Prozesse und eine kontinuierliche Produktion erfordern. Sie sind besonders effektiv in der Massenproduktion und in hochautomatisierten Umgebungen.

Merkmale: Rotationsproduktionslinien sind sehr flexibel und können mit mehreren Arbeitsstationen konfiguriert werden. Sie eignen sich gut für langfristige, hocheffiziente Produktionsaufgaben, bei denen es oft um komplexere Produkte geht.

Bananen-Produktionslinie

Entwickelt für Produkte, die spezielle Formen oder gekrümmte Verarbeitungswege erfordern, und bietet hohe Flexibilität.

Bananen-Produktionslinie

Entwickelt für Produkte, die spezielle Formen oder gekrümmte Verarbeitungswege erfordern, und bietet hohe Flexibilität.

Anwendungen: Dieser Produktionslinientyp wird für Prozesse verwendet, die gekrümmte Bahnen oder bestimmte Formen erfordern. Er eignet sich besonders für die Handhabung flexibler Materialien oder die Herstellung von Produkten mit komplexen Formen.

Merkmale: Die für ihre Anpassungsfähigkeit bekannte Bananenproduktionslinie kann Werkstücke mit einzigartigen Formen oder Winkeln verarbeiten und ist daher ideal für Produkte, die eine Verarbeitung mit variablen Winkeln oder spezifischen Formen erfordern.

Komplettlösung Von der Produktionslinie für Autositze

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

Schaummaschine

Schimmel

Mold Temperature Control Machine

Rohstoff

Kontaktieren Sie uns für ein umfassendes Angebot

UREXCEED-Maschinen sind 30% billiger als europäische Maschinen

FAQs Von der Produktionslinie für Autositze

Uniform foaming is achieved by precisely controlling the raw material mix ratios, injection pressure, and mold temperature. The mold temperature controller plays a key role in maintaining consistent heat distribution, ensuring that the foam expands evenly and cures uniformly.

The mold temperature machine (or mold temperature controller) heats or cools the mold to maintain a constant temperature. This is critical for controlling the foaming reaction, ensuring proper material flow, and ultimately achieving a high-quality, consistent product.

Regular maintenance is essential. It includes:

- Routine inspections and cleaning of molds, nozzles, and mixing heads.

- Calibration of dosing pumps and monitoring of injection pressure.

- Preventive maintenance schedules to reduce downtime and maintain optimal production efficiency.

In case of issues, check the following:

- Raw Material Mix: Ensure the correct ratios of polyol and isocyanate.

- Injection Parameters: Verify that the injection pressure and speed are set correctly.

- Mold Temperature: Confirm that the mold is at the required temperature.

- Release Agent Application: Ensure even application to prevent sticking and surface defects.

Safety and environmental compliance are ensured by:

- Adhering to strict operational protocols and safety guidelines.

- Using eco-friendly raw materials and release agents.

- Implementing proper ventilation and waste management systems to control emissions and protect workers.

Operators receive comprehensive training that includes:

- Detailed operation manuals and on-site training sessions.

- Remote technical support and troubleshooting assistance.

- Continuous updates on best practices to ensure efficient and safe production.

Wiedergabeliste

Transaction Case Of UREXCEED PU Car Seat Production Line

Good Review Of Car Seat Production Line

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

Die Produktionslinie von UREXCEED ist zuverlässig und effizient, steigert die Produktion und reduziert Ausfallzeiten. Wir sind mit der Ausrüstung und dem Support sehr zufrieden.

Sarah Müller DeutschlandWir sind mit der Sitzproduktionslinie von UREXCEED sehr zufrieden. Sie steigerte die Effizienz und sorgte für eine hohe Qualität. Das Team leistete großartigen technischen Support. Sehr empfehlenswert!

Juan Pérez MexikoUnsere Produktionseffizienz wurde mit der Sitzproduktionslinie von UREXCEED um 301 TP3T gesteigert. Die intelligenten Funktionen reduzierten die Fehlerquote und der Service war ausgezeichnet. Sehr zufrieden!

Abdul Aziz Vereinigte Arabische EmirateDie Produktionslinie von UREXCEED ist stabil, effizient und hochautomatisiert. Sie minimiert Fehler und steigert die Produktion. Sehr zu empfehlen!"

Carlos Mendoza SpanienWir haben mit dieser Sprühschaummaschine großartige Ergebnisse erzielt. Sie liefert eine gleichmäßige Beschichtung und ist leicht zu steuern.

Die Beschichtungsmaschine funktioniert reibungslos und trägt jedes Mal genau die richtige Menge Klebstoff auf. Sie ist eine großartige Ergänzung unserer Produktionslinie.

Eliot Davis Betriebsleiter

A Mexican automotive parts manufacturer sought to improve seat production efficiency and ensure stable product quality. They required a highly efficient and automated polyurethane car seat production line, including a high-pressure polyurethane foaming machine, mold temperature controller, seat molds, and a production line. After multiple discussions, we provided a customized, energy-efficient solution, optimizing key processes such as mold heating, release agent spraying, material injection, and foaming. The client was impressed by our equipment stability, uniform foaming, and one-stop service, leading to a successful order. After installation, we offered remote technical support and on-site training to ensure smooth production. The line is now fully operational, delivering high product yield and helping the client enhance efficiency while reducing costs.

Mexiko