The average equipment warranty period typically spans one to five years depending on the type of equipment, its complexity, and the manufacturer's confidence in product reliability. When it comes to maintenance response time guarantee, most industrial equipment providers aim to address issues within 24-48 hours, though this can vary significantly based on service agreements, equipment criticality, and geographical location factors.

Die wichtigsten Erkenntnisse

- Standard warranty coverage for industrial equipment generally ranges from 1-5 years, with variations by industry and equipment type

- Response times for maintenance typically fall within 24-48 hours, though critical equipment often has expedited service options

- Many manufacturers offer extended warranty options that provide additional coverage beyond the standard warranty period

- The distinction between warranty vs guarantee differences is important to understand when evaluating equipment protection plans

- Preventive maintenance programs can significantly reduce emergency repair needs and maximize equipment uptime during and after warranty periods

Warranty Periods Explained: Industry Standards and Variations

When purchasing industrial equipment, understanding the standard warranty coverage details is essential for making informed decisions about long-term operational costs. The typical warranty period ranges from one to five years, depending on various factors including equipment complexity, expected lifespan, and industry standards. Heavy machinery often comes with longer warranties than smaller, less expensive equipment due to the significant investment they represent.

Different industries have established their own manufacturer warranty duration norms. For example, construction equipment typically carries 1-2 year warranties, while specialized manufacturing equipment might offer 3-5 years of coverage. Medical equipment often features extended warranties due to strict reliability requirements and regulatory considerations. According to a 2022 Industry Today report, approximately 65% of industrial equipment comes with at least a two-year standard warranty.

Der equipment warranty period often reflects the manufacturer's confidence in their product's durability and reliability. Companies with robust quality control processes and extensive product testing typically offer longer warranties. Here's how warranty periods generally break down by equipment category:

- Basic mechanical equipment: 1-2 years

- Complex industrial machinery: 2-3 years

- High-precision equipment: 3-5 years

- Components and parts: 90 days to 1 year

- Software elements: Varies widely, from 90 days to lifetime support

When evaluating how long is equipment warranty, it's important to read the fine print. Some warranties cover parts but not labor, while others offer comprehensive coverage. Additionally, many manufacturers provide tiered warranty options, with basic coverage included in the purchase price and premium coverage available at additional cost.

Factors Determining Warranty Duration

Manufacturers don't arbitrarily decide warranty periods. Instead, they rely on Accelerated Life Testing (ALT) to determine how long their products will likely perform under normal conditions. This scientific approach subjects equipment to extreme conditions—high temperatures, continuous operation, excessive loads—to simulate years of wear in a compressed timeframe. The data from these tests helps manufacturers predict failure rates and set appropriate warranty periods that balance customer satisfaction with financial risk.

Market competition significantly influences warranty duration decisions. When one manufacturer extends their warranty period, competitors often follow suit to remain competitive. This has gradually pushed industry standards toward longer warranties in many sectors. According to a Machine Design analysis, warranty periods have increased by an average of 8 months across industrial equipment categories over the past decade.

Customer expectations and product reliability metrics create a complex equation for determining the ideal warranty period. Manufacturers must balance:

- Mean Time Between Failures (MTBF) statistics

- Cost of warranty claims versus customer goodwill

- Component reliability and supply chain considerations

- Installation environment and usage patterns

- Service network capabilities and response capacity

For equipment buyers, understanding these factors helps in negotiating better extended warranty options for equipment. When manufacturers have high confidence in their product's reliability, they're often more willing to offer favorable warranty terms. Savvy purchasers can leverage this knowledge during negotiations, particularly for large-scale equipment acquisitions through industrial equipment providers.

Maintenance Response Time: What to Expect

While warranty duration addresses how long coverage lasts, the maintenance response time guarantee determines how quickly help arrives when equipment fails. In most industrial settings, standard response times range from 24-48 hours for non-critical equipment. However, for production-critical machinery, many service providers offer expedited response options of 4-8 hours, sometimes with additional priority service fees.

Equipment criticality plays a major role in determining appropriate response times. A machine that halts an entire production line requires faster attention than auxiliary equipment. This criticality-based approach is reflected in tiered service agreement terms and conditions that many manufacturers and third-party service providers offer. These agreements typically outline:

- Response time commitments based on equipment type

- Escalation procedures for emergency situations

- Hours of service availability (business hours vs. 24/7)

- Remote diagnostics capabilities and initial response protocols

- Parts availability guarantees

Service Level Agreements (SLAs) formalize the emergency repair service timeline expectations between equipment owners and service providers. These legally binding documents specify not just how quickly a technician will respond, but also target resolution times and performance metrics. According to Plant Engineering, well-structured SLAs can reduce downtime by up to 37% compared to informal service arrangements.

Several factors may extend or reduce typical response windows, including:

Geographic location significantly impacts response times. Remote facilities often face longer waits than urban locations with nearby service centers. Weather conditions, particularly in regions prone to extreme weather events, can further complicate timely service delivery. Equipment complexity also plays a role—highly specialized machinery may require technicians with specific expertise who aren't always immediately available.

Optimizing Maintenance Support

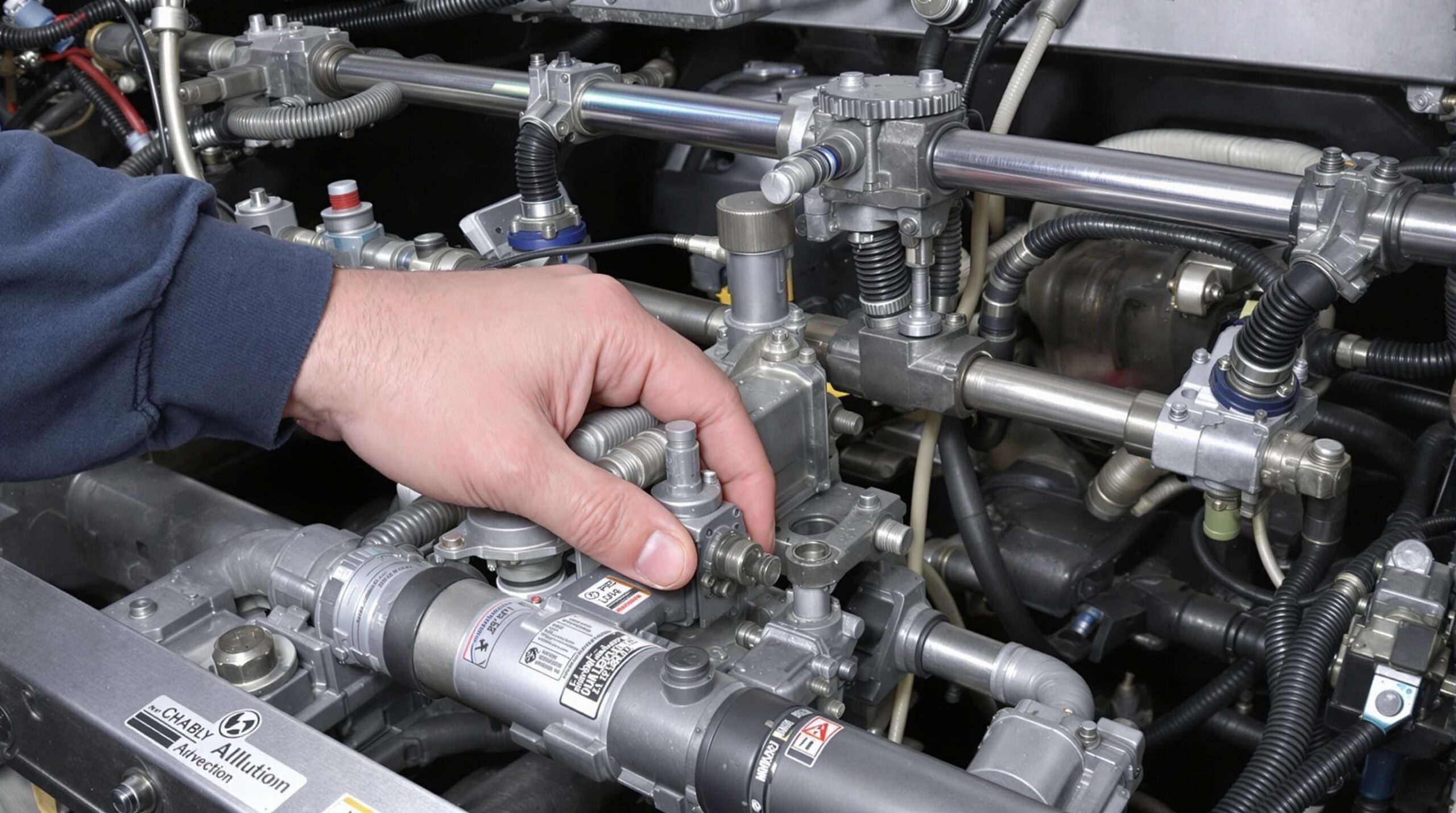

Preventive maintenance represents one of the most effective strategies for reducing unexpected downtime and maximizing equipment reliability. By scheduling regular service interventions based on manufacturer recommendations, equipment owners can identify potential issues before they cause failures. This proactive approach not only extends equipment life but also reduces the need for emergency repairs with their associated rapid response requirements and production disruptions.

Modern maintenance approaches increasingly incorporate predictive analytics to anticipate equipment failures before they occur. By monitoring key performance indicators and employing machine learning algorithms, maintenance teams can detect subtle changes in equipment behavior that signal impending problems. According to a Manufacturing Tomorrow study, predictive maintenance can reduce unplanned outages by up to 50% while cutting maintenance costs by 10-40%.

The relationship between Mean Time To Repair (MTTR) and response efficiency directly impacts equipment availability. MTTR measures the average repair turnaround for industrial equipment—the time from failure to restored operation. Improved response times are just one component of reducing MTTR; other factors include:

- Parts availability and inventory management

- Technician skill level and training

- Diagnostic tool effectiveness

- Documentation quality and accessibility

- Equipment design for serviceability

For critical equipment, special care strategies can minimize emergency maintenance needs. These might include more frequent inspections, redundant systems, condition monitoring sensors, and prioritized spare parts inventories. Some companies even invest in on-site technicians for their most critical equipment, eliminating response time concerns entirely for these assets.

Maximizing Equipment Reliability Through Warranty and Maintenance

A strong correlation exists between robust warranty policies and equipment performance. Manufacturers who offer longer warranties typically invest more in quality control, materials, and engineering—resulting in more reliable products. When evaluating equipment purchases, the warranty period often serves as an indicator of expected reliability. Equipment with longer warranty coverage generally demonstrates the manufacturer's confidence in their product's durability.

When considering extended warranty options for equipment, buyers should evaluate the true value proposition rather than making automatic decisions. Extended warranties make financial sense when:

- Equipment is mission-critical with high downtime costs

- Repair costs are likely to be substantial relative to the warranty price

- In-house maintenance capability is limited

- The equipment has a history of requiring service interventions

- Usage patterns will be particularly demanding

Effective maintenance response systems complement warranty coverage by minimizing downtime when issues do occur. Even the most comprehensive warranty provides limited value if service response is slow or ineffective. This is why savvy equipment buyers evaluate both warranty coverage and service capabilities when making purchasing decisions. Some manufacturers excel in product quality but fall short in service delivery, while others might offer average products backed by exceptional support.

Best practices for managing equipment throughout its lifecycle integrate warranty considerations with maintenance planning. This holistic approach includes:

- Documenting all warranty terms and expiration dates

- Scheduling preventive maintenance to preserve warranty validity

- Building relationships with service providers before emergencies occur

- Training operators to avoid warranty-voiding practices

- Evaluating third-party service options as warranties expire

Verstehen der warranty vs guarantee differences provides additional clarity when evaluating equipment protection plans. While these terms are sometimes used interchangeably, they typically have distinct meanings in industrial contexts. Warranties usually represent the manufacturer's promise to repair defects within a specific timeframe, while guarantees often focus on performance metrics or outcomes. Some equipment comes with both—a warranty covering defects and a guarantee regarding specific performance capabilities.

Häufig gestellte Fragen

What is the standard warranty period for most industrial equipment?

Most industrial equipment comes with warranty periods ranging from one to five years, with two years being the most common standard warranty duration. Heavy machinery and more expensive equipment typically feature longer warranty periods than simpler, less costly items.

Can warranty periods be negotiated when purchasing equipment?

Yes, warranty periods are often negotiable, especially for large purchases or when buying multiple units. Many manufacturers are willing to extend warranty coverage as a sales incentive, particularly when competing against other vendors with similar products.

What's the difference between parts warranty and labor warranty?

A parts warranty covers the cost of replacement components but not the labor to install them, while labor warranty covers the service technician's time. Comprehensive warranties include both parts and labor, while limited warranties might cover only components or offer different coverage periods for parts versus labor.

How do maintenance response times vary for different equipment types?

Response times typically vary based on equipment criticality, with production-critical machinery receiving faster response (often 4-8 hours) than supporting equipment (typically 24-48 hours). Specialized equipment might have longer response times due to the need for technicians with specific expertise.

What factors can void an equipment warranty?

Common warranty-voiding factors include unauthorized modifications, improper installation, neglecting required maintenance, using unapproved parts or consumables, operating equipment outside specified environmental conditions, and damage from misuse or accidents. Always review warranty terms carefully to understand specific limitations.

Is it worth purchasing an extended warranty for industrial equipment?

Extended warranties are typically worthwhile for mission-critical equipment where downtime is extremely costly, when repair expenses are likely to be high relative to the warranty cost, or when in-house maintenance capabilities are limited. For less critical or easily serviceable equipment, self-insuring may be more cost-effective.

How do digital monitoring systems affect maintenance response times?

Digital monitoring systems can significantly reduce effective response times by enabling remote diagnostics, providing early warning of developing issues, and allowing technicians to arrive prepared with the right parts and tools. Some systems even permit remote repairs for software or configuration issues, eliminating physical response time entirely.