What is the Replacement Cycle of the Core Components of the High-Pressure Machine

Verstehen der replacement cycle of high-pressure machinery core components is crucial for maximizing equipment efficiency while minimizing unexpected downtime. The lifespan of critical components in pressure washers and similar high-pressure equipment typically extends to around 10 years, though this duration heavily depends on maintenance practices, usage patterns, and the quality of preventative care implemented throughout the machine's operational life.

Die wichtigsten Erkenntnisse

- Regular oil maintenance is the primary determiner of pump longevity in high-pressure machines

- Most quality pressure system components have a 10-year potential lifespan with proper care

- Early detection of wear patterns through scheduled inspections can prevent catastrophic failures

- Different replacement cycles apply to various components based on their exposure to pressure and friction

- Commercial usage typically requires 3-5 times more frequent component replacement than residential applications

Understanding High Pressure Machinery Lifespan Fundamentals

High-pressure machines represent significant investments for both industrial operations and professional cleaning services. Their operational effectiveness depends heavily on the condition of core components that manage pressure generation and distribution. The typical pressure washer can last approximately 10 years, but this timeline varies dramatically based on usage intensity, environmental factors, and maintenance practices.

According to data from the Pumps & Systems journal, the pressure cycle impact on component wear accelerates dramatically when machines operate at the upper limits of their rated capacity for extended periods. Components experiencing consistent high-pressure cycles may require replacement at intervals 40-60% shorter than those used intermittently or at moderate pressure settings.

Critical Pump Maintenance Schedule

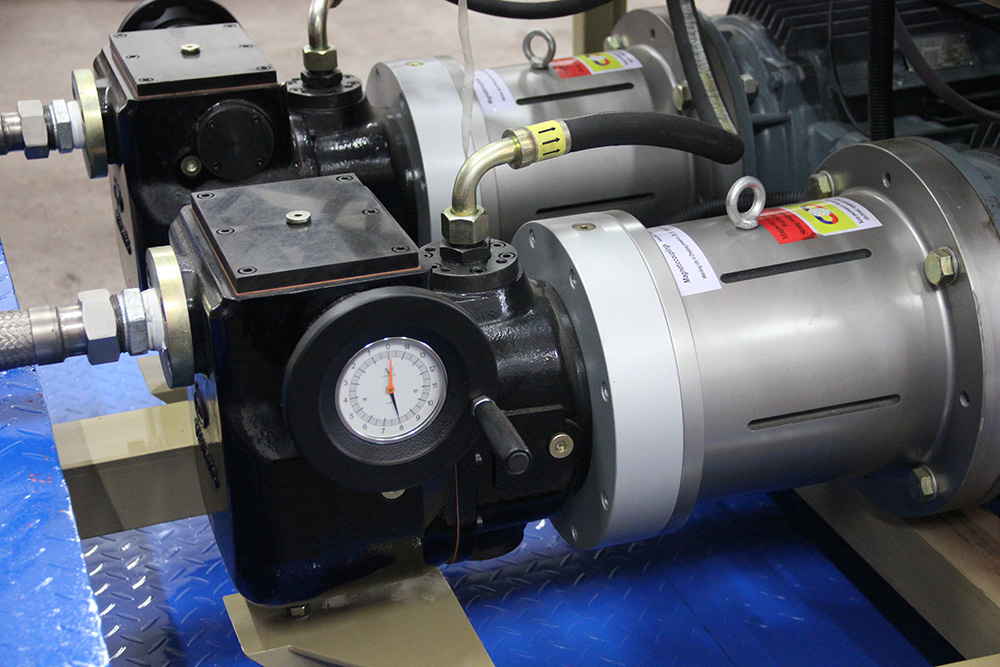

The pump serves as the heart of any high-pressure system, making its maintenance schedule paramount to overall system longevity. Following industry standards for machinery component replacement can significantly extend your equipment's productive lifespan while maintaining optimal performance.

The initial pump oil change should occur after the first 50 hours of operation, establishing a baseline of protection for new components. Subsequently, regular pump oil changes should follow this schedule:

- Standard oils: Every 100 hours or three months (whichever comes first)

- Premium Cat brand oils: Extended interval of 500 hours

- Other quality synthetic formulations: Approximately 300 hours

Adhering to this preventive maintenance schedule for high-pressure machines ensures optimal lubrication of moving parts, reducing friction and heat generation that accelerate wear. A study by the Hydraulic Institute found that proper oil maintenance alone can extend pump life by 30-50% compared to neglected equipment.

Engine Maintenance Requirements

For engine-powered high-pressure equipment, the engine requires distinct maintenance protocols that complement pump care. The engine's maintenance schedule differs slightly from the pump system but remains equally important to overall performance and longevity of the high-pressure polyurethane foaming machine and similar equipment.

Key engine maintenance milestones include:

- First engine oil change: After initial 20 hours or within one month of first use

- Regular engine oil changes: Every 100 hours or 6 months of operation

- Air filter inspection and cleaning: Every 25 hours under normal conditions

- Air filter inspection and cleaning: Every 10 hours in dusty environments

- Spark plug inspection: Every 100 hours with replacement as needed

These maintenance intervals reflect operating conditions and component durability factors that directly impact engine performance. According to Machinery Lubrication, engines operating in high-temperature or dusty environments may require maintenance intervals shortened by 25-40% to maintain equivalent component life expectancy.

Warning Signs Your Pump Needs Attention

Recognizing failure signs in high-pressure system components early can prevent cascading damage throughout the system. Being attentive to subtle changes in machine performance often provides the opportunity to replace individual components before complete failure occurs.

Key indicators that warrant immediate inspection include:

- Pressure fluctuations or cycling: The pump rapidly turning on and off

- Decreased pressure output: Unable to maintain rated PSI

- Unusual noises: Grinding, knocking, or whining sounds during operation

- Visible leaks: Oil or water appearing beneath the machine

- Excessive vibration: Unstable operation indicating internal component wear

- Difficulty starting: Engine or motor struggles to initiate operation

When these symptoms appear, consulting the manufacturer's specifications for hydraulic parts replacement frequency guidelines can help determine whether immediate replacement is necessary or if additional maintenance might extend component life temporarily. Components approaching the 10-year mark generally warrant closer monitoring regardless of apparent condition.

Replacement Parts and Components

Understanding the replacement cycle for specific components helps establish cost-effective maintenance planning. Different parts of high-pressure systems wear at varying rates based on their exposure to pressure, friction, and environmental factors.

Common replacement parts and their typical lifespan include:

- O-rings and seals: 300-500 hours of operation

- Spray nozzles: 500-700 hours (depending on water quality)

- High-pressure hoses: 2-3 years with regular use

- Spray guns and wands: 3-5 years

- Pump pistons and valves: 5-7 years with proper maintenance

- Electric motors: 7-10 years

- Engine components: Variable based on maintenance (5-10 years)

Der OEM vs aftermarket parts longevity comparison reveals that genuine manufacturer components typically last 15-30% longer than generic alternatives, though premium aftermarket options from reputable suppliers often offer comparable durability at reduced cost. A comprehensive study published in Procedia Manufacturing found that precision-engineered components matching original specifications delivered nearly identical lifespan metrics compared to OEM parts.

Extending Component Lifespan Through Preventative Care

Implementing best practices for pressure vessel maintenance significantly influences the replacement cycle of core components. Preventative care represents the most cost-effective approach to extending machinery lifespan while maintaining operational efficiency.

Essential preventative maintenance practices include:

- Regular inspection protocols: Weekly visual checks of accessible components

- Proper startup and shutdown procedures: Following manufacturer guidelines

- Clean water supply: Using filtered water to prevent abrasive particles

- Appropriate nozzle selection: Using correctly sized nozzles to prevent pump strain

- Temperature management: Avoiding operation in extreme temperatures

- Proper storage: Winterizing equipment in cold climates

- Using the correct chemicals: Only using detergents formulated for high-pressure equipment

Implementing these practices can extend component lifespan by 40-60% compared to neglected equipment. Research from the Association for Manufacturing Technology indicates that regular preventative maintenance delivers a return on investment between 500-700% through reduced replacement costs and minimized downtime.

The Economics of Maintenance vs. Replacement

Conducting a thorough cost analysis of high-pressure machinery overhauls reveals the financial advantages of scheduled maintenance versus reactive replacement. Understanding the economics helps operations managers make data-driven decisions about equipment maintenance budgets and replacement planning.

The financial comparison between proactive and reactive approaches typically shows:

- Scheduled maintenance costs: Approximately 15-20% of equipment replacement value annually

- Emergency repair costs: Typically 3-5 times higher than planned maintenance

- Productivity losses from unplanned downtime: Often exceeds direct repair costs

- Residual value retention: Well-maintained equipment retains 30-40% higher resale value

According to the Plant Engineering Maintenance Survey, the average cost of downtime in industrial operations ranges from $5,000 to $50,000 per hour depending on the industry and application. This makes the economic case for regular component replacement according to manufacturer guidelines compelling even before considering the potential safety implications of component failure.

Commercial vs. Residential Usage Considerations

Der replacement cycle varies significantly between commercial and residential applications due to fundamental differences in usage patterns, operating conditions, and expected performance standards. Understanding these distinctions helps establish appropriate maintenance schedules for different usage scenarios.

Key differences include:

- Duty cycle: Commercial equipment often operates 4-8 hours daily vs. 2-5 hours monthly for residential use

- Operating pressure: Commercial applications typically utilize higher sustained pressure

- Water quality variation: Commercial equipment often encounters more diverse water quality conditions

- Operator expertise: Commercial operators generally have more technical knowledge

- Maintenance resources: Commercial operations usually have established maintenance protocols

These differences translate to commercial equipment requiring component replacement approximately 3-5 times more frequently than residential equipment, even with equivalent quality components. The Industrial Cleaning Equipment Manufacturers Association notes that commercial-grade components are typically engineered with this accelerated replacement cycle in mind, offering increased serviceability and modular design to facilitate efficient maintenance.

Technology Advancements Affecting Component Longevity

Recent technological innovations have significantly improved component durability in modern high-pressure equipment. These advancements offer longer replacement cycles while maintaining performance standards that meet or exceed previous generation equipment.

Notable technological improvements include:

- Advanced materials science: Ceramic plungers and stainless steel components with superior wear characteristics

- Computer-optimized fluid dynamics: Reduced internal turbulence decreasing component stress

- Variable frequency drives: Allowing pumps to operate at optimal efficiency points

- Precision manufacturing techniques: Tighter tolerances reducing premature wear

- Smart monitoring systems: Real-time component health assessment

Equipment manufactured within the past five years often incorporates these technologies, potentially extending replacement intervals by 20-30% compared to older equipment. Research from the Hydraulics & Pneumatics institute indicates that these technological advancements have increased the mean time between failures for critical components by as much as 40% in properly maintained systems.

Developing a Comprehensive Replacement Strategy

Creating a systematic approach to component replacement that balances preventative maintenance with operational requirements ensures optimal equipment performance while managing maintenance costs effectively. A well-designed strategy considers both manufacturer recommendations and operational realities.

Elements of an effective replacement strategy include:

- Component tracking system: Documenting installation dates and service history

- Tiered replacement schedules: Categorizing components by criticality and wear rates

- Inventory management: Maintaining critical replacement parts on hand

- Planned downtime coordination: Scheduling replacements during operational lulls

- Technician training: Ensuring proper installation and calibration procedures

- Performance benchmarking: Establishing baseline metrics to identify degradation

By implementing this strategic approach, operations can avoid both premature replacement (which inflates maintenance costs) and delayed replacement (which increases failure risk). The International Society of Automation estimates that organizations implementing structured replacement programs reduce unplanned downtime by 30-50% compared to reactive maintenance approaches.

FAQ: High-Pressure Equipment Component Replacement

How often should pump oil be changed in a high-pressure machine?

Pump oil should be initially changed after the first 50 hours of operation, then every 100 hours or three months with standard oils. Premium synthetic oils may extend this interval to 300-500 hours depending on the brand and operating conditions.

What is the typical lifespan of a high-pressure pump?

With proper maintenance, a quality high-pressure pump can last 7-10 years in residential applications and 3-5 years in commercial settings. Regular oil changes, proper water filtration, and avoiding dry operation are key factors in maximizing pump life.

Are OEM replacement parts worth the additional cost?

OEM parts typically offer 15-30% longer service life compared to generic alternatives, making them cost-effective for critical components despite higher initial costs. For non-critical components, high-quality aftermarket parts often provide adequate performance at lower cost.

How can I tell when my pressure washer pump needs replacement?

Key signs include pressure fluctuations, unusual noises (knocking or grinding), visible oil leaks, inability to build or maintain proper pressure, excessive vibration, and water in the pump oil giving it a milky appearance.

What factors most significantly reduce component lifespan in high-pressure equipment?

The most damaging factors include running the pump dry, using unfiltered water containing abrasive particles, operating at maximum pressure continuously, exposure to freezing temperatures, chemical incompatibility, and neglecting regular oil changes.