Le distributeur de colle is one of the core devices in modern production lines, widely used in industries such as packaging, automotive, electronics, and construction. As an efficient and precise glue coating device, it ensures even application of adhesives on product surfaces for excellent bonding. However, like any mechanical equipment, the glue dispensing machine may encounter some common failures during prolonged use, which can affect production efficiency and product quality. To help companies improve their production line efficiency, reduce downtime, and extend the service life of the equipment, this article will provide a detailed analysis of common failures of distributeurs de colle, along with corresponding solutions and tips for maintenance and care.

Common Issues and Solutions

Glue Clogging

Problem Description: Glue clogging is one of the most common issues with glue dispensing machines. It is typically manifested by the inability of glue to flow smoothly, resulting in nozzle blockages that prevent proper dispensing and can even lead to machine downtime, increasing production costs.

Causes :

- High Glue Viscosity:If the viscosity of the glue is too high, its flowability is poor, leading to blockages in pipes and nozzles.

- Glue Solidification:If glue is left in the pipes for long periods or exposed to improper temperature, it may solidify and block the system.

- Glue Containing Impurities or Particles:Unfiltered glue often contains impurities, which can accumulate in the nozzles and pipes, causing clogs.

- Nozzle Wear or Clogging:Nozzles may become worn out or accumulate residual glue, preventing the proper dispensing of glue.

Solutions:

- Control Glue Viscosity:Adjust the glue’s viscosity by heating or modifying its formulation to ensure it flows properly.

- Regular Cleaning:After long periods of inactivity, clean the dispensing system with an appropriate solvent to prevent glue from solidifying in the pipes.

- Install Glue Filtering System:Use a filter to remove impurities before the glue enters the dispensing system.

- Regular Nozzle Replacement:Check and clean the nozzle regularly to prevent wear and tear, and replace them as needed to ensure smooth dispensing.

Uneven Coating

Problem Description: Uneven coating is another common failure. It occurs when the adhesive is applied unevenly across the product’s surface, resulting in poor bonding, surface defects, or waste of material.

Causes :

- Unstable Glue Flow Rate:Variations in glue flow or pressure fluctuations lead to uneven application.

- Nozzle Wear or Blockage:Worn-out or clogged nozzles cause inconsistent dispensing.

- Incorrect Nozzle Positioning:If the nozzle’s distance or angle relative to the product is incorrect, it can lead to uneven coating.

- Air Bubbles in the Glue:If the glue contains air bubbles, it may result in an unstable dispensing process, causing uneven application.

Solutions:

- Adjust Glue Flow Rate and Pressure:Regularly check and calibrate glue pressure and flow to ensure stability.

- Regular Nozzle Inspection and Cleaning:Inspect nozzles for wear and clogging, and clean or replace them as necessary.

- Optimize Nozzle Position and Angle:Adjust the nozzle’s position and angle to ensure consistent dispensing and coating.

- Use Degassing Systems:Implement a degassing system to remove air bubbles from the glue and ensure steady flow.

Glue Leakage

Problem Description: Glue leakage is a common failure that results in excess glue spilling out of the system, leading to waste, contamination, and inefficiencies in the production process.

Causes :

- Damaged Seals:Worn or damaged seals can cause glue to leak out of the system.

- Loose Nozzle and Pipe Connections:Poor connections between the nozzle and pipe can lead to leakage.

- Low Glue Viscosity:If the glue’s viscosity is too low, it may leak out of the system under high pressure.

- Excessive Glue Pressure:High pressure in the system can cause glue to overflow or leak.

Solutions:

- Regular Seal Replacement:Inspect and replace seals, particularly at nozzle and pipe connection points, to prevent leaks.

- Tighten Nozzle and Pipe Connections:Ensure all connections between nozzles and pipes are secure to avoid leaks.

- Adjust Glue Viscosity:Modify the glue’s formulation or temperature to ensure it has an appropriate viscosity to prevent leakage.

- Optimize Glue Pressure:Monitor and adjust glue pressure to ensure it stays within safe operational limits.

Machine Failures or Sudden Shutdowns

Problem Description: A sudden machine shutdown or instability can disrupt the production process, leading to downtime and production delays.

Causes :

- Unstable Power Supply:Power fluctuations or electrical failures may cause the dispensing machine to stop working.

- Control System Failures:Failures in the PLC, sensors, or other control systems can prevent the machine from operating correctly.

- Overheating:Key components like the motor or pump may overheat, triggering the machine’s automatic shutdown for protection.

- Lack of Lubrication:Insufficient lubrication in mechanical parts leads to friction, causing jams or breakdowns.

Solutions:

- Check the Power Supply:Ensure the power supply is stable. Use a voltage stabilizer to prevent fluctuations.

- Regular Control System Inspections:Periodically check and calibrate the control systems to ensure proper functioning.

- Monitor Temperature:Keep an eye on the temperature of critical components and address overheating issues before they lead to shutdowns.

- Regular Lubrication:Lubricate moving parts regularly to reduce friction and prevent mechanical issues.

Maintenance and Care Tips

Entretien quotidien

Daily maintenance is crucial for keeping the glue dispensing machine running smoothly and preventing major issues. The key aspects of daily maintenance include:

- Cleaning:After each use, clean the nozzle, pipe, and glue tank to prevent any residual glue from hardening and causing blockages.

- Nozzle Check:Inspect the nozzle for any wear or clogging, and clean it thoroughly after every use.

- Lubricating Mechanical Parts:Lubricate moving parts like motors and gears at least once a month to reduce wear and tear.

- Checking Connections:Ensure that all pipe and nozzle connections are tight and secure to avoid leaks.

Preventive Maintenance

Preventive maintenance involves measures taken to prevent failures before they occur, such as:

- Filter System Maintenance:Clean and replace glue filters regularly to ensure that no impurities enter the dispensing system.

- Contrôle de la température :Monitor the temperature control system to ensure that glue is heated evenly and doesn’t overheat, which could affect its performance.

- System Calibration:Periodically check and calibrate sensors, flow meters, and pressure gauges to maintain accuracy and consistency in glue dispensing.

Troubleshooting Training

Training operators on troubleshooting techniques is essential for maintaining the machine’s functionality and minimizing downtime:

- Regular Training:Provide regular training to operators on how to diagnose and solve common machine issues.

- Troubleshooting Guidelines:Develop clear guidelines for troubleshooting machine faults to ensure quick and efficient repairs.

- Spare Parts Management:Maintain a stock of essential spare parts, such as nozzles, seals, and filters, to reduce downtime during repairs.

The glue dispensing machine plays a vital role in ensuring high-quality adhesive application in various industries. However, like any complex machinery, it is prone to common failures such as glue clogging, uneven coating, leakage, and sudden shutdowns. By understanding the causes of these issues and implementing effective solutions, manufacturers can significantly reduce downtime, increase production efficiency, and extend the service life of the equipment.

Regular maintenance and preventive measures, including proper lubrication, cleaning, and calibration, are essential to keep the machine operating at peak performance. Additionally, training operators to identify and troubleshoot common issues ensures that they can quickly address any problems that arise, minimizing production delays. By following these best practices and maintaining a proactive approach to machine care, companies can achieve more reliable and cost-effective operations.

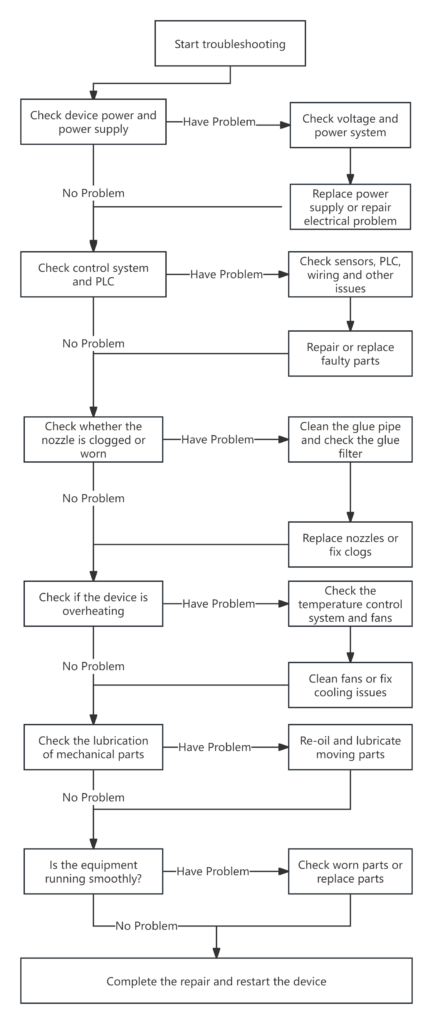

Equipment Maintenance and Common Fault Troubleshooting Flowchart

Flowchart Explanation:

- Vérifier l'alimentation électrique: First, confirm whether the equipment has a proper power supply. If there’s an issue, check the power system, voltage, or stabilizers.

- Check Control System: If the power supply is normal, check the control system, especially the PLC and sensors for proper functioning.

- Check Glue Supply System: Ensure the glue flow is normal. If not, clean the glue pipes, check the filter system, and resolve any clogs.

- Check Nozzle: Worn-out or clogged nozzles are common causes of poor dispensing. Regular checks and cleaning or replacing of the nozzle are necessary.

- Check Machine Temperature: Overheating could be caused by a failure in the temperature control system or inadequate cooling. Cleaning the fans or addressing cooling issues can resolve this.

- Check Mechanical Part Lubrication: Lack of lubrication on moving parts can lead to high friction and wear. Ensure the moving components are properly lubricated.

- Check for Smooth Machine Operation: Verify whether the equipment is running smoothly and without abnormal vibrations or noises. Replace any worn or damaged parts as needed.

This flowchart applies to general troubleshooting of a glue dispensing machine and can be adjusted for specific models or situations. By following a structured troubleshooting and maintenance process, downtime can be minimized, and the equipment will remain in optimal condition for longer.