In the stamping production of refrigerator sheet metal parts, small batch and multi-variety order structures have become the norm. Frequent mold changes, if not handled properly, will not only affect the production line cycle, but also cause mold damage and increase labor costs.

How can we achieve fast die change and shorten downtime without affecting quality? The SMED (Single-Minute Exchange of Die) method provides us with a complete set of optimization ideas.

Application of SMED seven-step method in refrigerator stamping

1. Mold change information prediction

Issue mold change instructions in advance through the ERP or MES system, prepare the required molds, materials and fixtures, and avoid the waste of “people waiting for molds” due to information lag.

2. Standardization of mold pre-assembly and disassembly process

Auxiliary equipment such as mold lifters and mold transfer arms are introduced to ensure smooth loading of the mold on the machine, and standardized disassembly operation instructions are used to reduce the time for transportation and positioning.

3. Separation of internal and external operations

“Internal operations” such as mold adjustment and press parameter setting are carried out in parallel with “external operations” such as mold handling and material preparation to avoid serial interference.

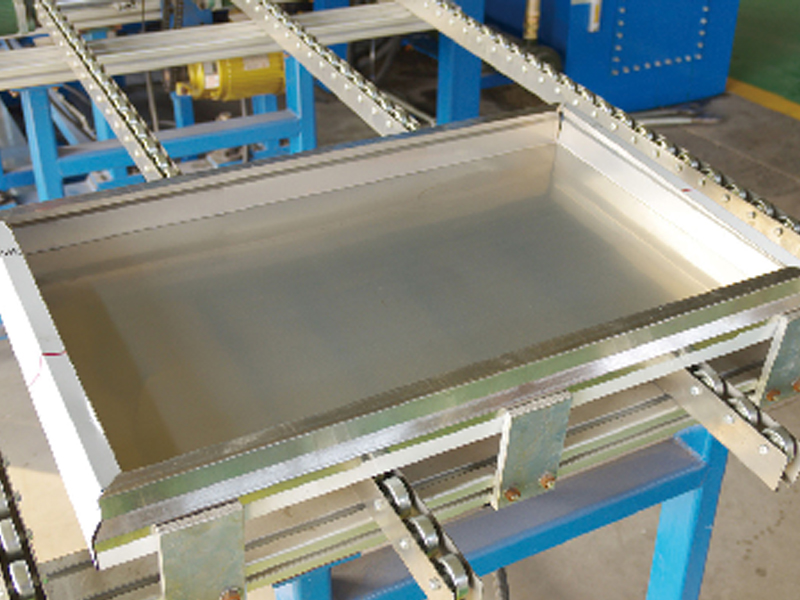

4. Magnetic template rapid clamping technology

Using an electrically controlled permanent magnet mold system instead of traditional bolt clamping, mold clamping can be completed in just 30 seconds , greatly shortening downtime and improving repeated mold loading accuracy.

5.Automation system integration

Equipped with a mold-changing trolley, automatic alignment device and parameter memory system , mold replacement and initialization settings can be completed with one click, reducing operating errors and physical exertion.

6. Optimization of operation process parameters

Standardize each mold changing operation process, adopt time node control and data statistics, and ensure that the mold changing time is stably controlled within 15 minutes .

7. PDCA continuous improvement

Regularly review mold change data, identify bottlenecks, form a continuous optimization mechanism , and continuously improve mold change efficiency and safety.

Technology upgrade and implementation results

Technical means | Improved results |

Electric controlled magnetic template | Clamping time from 8 minutes → 30 seconds |

Automatic mold changing system | Manual operations reduced by more than 70% |

Process standardization + information management | Total mold change time from 60 minutes to 15 minutes |

Improved equipment utilization | The effective daily operating time of each punch press increased by 40%+ |

The best balance between cost and efficiency

6 and 12 months compared to the loss of production capacity caused by slow mold changes .

We recommend that in the process of implementing SMED, automation upgrades and lean management be promoted simultaneously to avoid excessive equipment investment or safety hazards caused by excessive pursuit of speed.

Conclusion: Small batches can also be highly efficient, the key lies in mold change management

In the small-batch refrigerator sheet metal production, rapid mold change is not only related to production efficiency, but also to equipment utilization, labor costs and product delivery time.

If you are facing bottlenecks in stamping automation or die change efficiency, please contact us to obtain customized SMED optimization solutions, or make an appointment to visit our model factory.