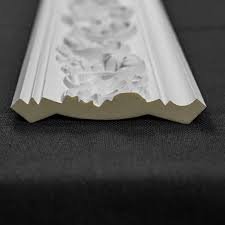

In the interior decoration industry, the choice of materials directly affects the final quality, durability, environmental friendliness, and overall value of the project. Over recent years, Polyuréthane (PU) materials have become increasingly popular due to their excellent performance and cost-effectiveness. However, when choosing materials, it is essential to consider the trade-offs in terms of performance, price, et impact environnemental. This article provides a detailed comparison of Polyuréthane (PU) with other traditional materials such as Bois, Ceramic Tiles, et Plaque de plâtre, focusing on performance, price, and environmental aspects.

Performance Comparison Between Polyurethane and Other Decoration Materials

Compared with other common interior decoration materials (such as wood, gypsum board, glass, PVC), polyurethane has unique advantages, but it also has challenges in terms of cost and construction. The following is a comparative analysis of polyurethane and these materials:

Attributs | Polyuréthane | Bois | Plaque de plâtre | PVC |

Taille du marché mondial en 2023 | $72 milliards (marché total) | 1 milliard TP4T30 (décoration en bois) | 1 milliard TP4T15 (plaques de plâtre) | 1 milliard TP4T50 (produits en PVC) |

Taux de croissance annuel du marché | 5.2% | 3.5% | 3.2% | 4.0% |

Principales applications | Décoration d'intérieur, Revêtements de sol, Plafonds, Décoration murale | Sols, murs, meubles | Murs, Plafonds | Sols, murs, tuyaux |

Pénétration du marché | 25%-30% | 20%-25% | 15%-20% | 15%-18% |

Impact environnemental | Faible teneur en COV, recyclable | Journalisation, consommation de ressources | Production à forte consommation d'énergie et recyclabilité limitée | Production à forte consommation énergétique, difficile à recycler |

Coût initial | Haut | Moyen | Faible | Faible |

Durabilité | Haut | Moyen | Faible | Moyen |

Durabilité

Matériel | Compressive Strength (MPa) | Durée de vie | Résistance aux chocs |

Polyuréthane | 0.1–1.5 | 10–20 years | Excellent |

Bois | 30–70 | 5–20 years | Medium (susceptible to moisture) |

Ceramic Tiles | 40–100 | 20+ years | Weak (fragile) |

Plaque de plâtre | 1–5 | 5–10 years | Weak (susceptible to damage) |

- Polyuréthane: Polyurethane foam materials have excellent compressive strength ranging from 0.1–1.5 MPa, making them highly durable and able to withstand pressure over time. The lifespan is 10–20 yearsfor foam boards and 5–10 years for polyurethane coatings.

- Bois: Ordinary wood has a compressive strength of 30–50 MPa(higher for hardwoods), but wood is prone to swelling and rotting in high-moisture environments. The lifespan of untreated wood is 5–10 years, et 15–20 years with proper treatment.

- Ceramic Tiles: Ceramic tiles are highly durable with a compressive strength of 40–100 MPabut are prone to breakage upon impact. The lifespan is typically 20+ years.

- Plaque de plâtre: Gypsum board has a much lower compressive strength of 1–5 MPa, and its lifespan is around 5–10 years.

Isolation acoustique

Matériel | Sound Insulation (dB) | Application Scenario |

Polyuréthane | 28–32 | High noise reduction areas like home theaters and conference rooms |

Bois | 15–25 | Low noise reduction areas, primarily for aesthetic use |

Ceramic Tiles | 20–30 | Not ideal for soundproofing, used for decoration |

Plaque de plâtre | 25–30 | Suitable for basic sound insulation in office and residential spaces |

- Polyuréthane: High-density polyurethane foam provides excellent sound insulation, with a noise reduction of 28–32 dB. This makes it ideal for areas that require high noise isolation, such as home theaters and conference rooms.

- Bois: Wood generally offers a lower sound insulation performance, ranging from 15–25 dB, and is more suitable for decorative purposes rather than soundproofing.

- Ceramic Tiles: Ceramic tiles provide only moderate sound insulation, around 20–30 dB, and are not ideal for soundproofing purposes.

- Plaque de plâtre: Gypsum board offers basic sound insulation at around 25–30 dB, suitable for residential and office applications but not for high-noise areas.

Isolation thermique

Matériel | Conductivité thermique (W/m·K) | Insulation Effectiveness | Suitable Environments |

Polyuréthane | 0.022–0.028 | Excellent | Cold regions, energy-efficient buildings |

Bois | 0.12–0.15 | Bien | Warm regions, residential spaces |

Ceramic Tiles | 1.0–1.5 | Pauvre | Non-insulating, decorative use |

Plaque de plâtre | 0.3–0.5 | Pauvre | Interior walls, ceilings (not for insulation) |

- Polyuréthane: Polyurethane has a thermal conductivityof 022–0.028 W/m·K, which is one of the best insulation performances among common building materials, making it highly effective in energy-efficient and cold-weather buildings.

- Bois: Wood offers moderate thermal insulation with a thermal conductivityof 12–0.15 W/m·K, suitable for warm climates and as a decorative material in homes.

- Ceramic Tiles: Ceramic tiles have a high thermal conductivity of 0–1.5 W/m·K, offering poor insulation properties and are not suitable for thermal insulation applications.

- Plaque de plâtre: Gypsum board’s thermal conductivityis 3–0.5 W/m·K, and like ceramic tiles, it offers poor thermal insulation.

Résistance au feu

Matériel | Fire Rating | Résistance au feu | Suitable Applications |

Polyuréthane | B2 (Combustible) or B1 (Flame-retardant) | Needs fire treatment | High-temperature areas, thermal insulation |

Bois | B3 (Flammable) | Flammable (needs treatment) | Needs fire treatment in construction |

Ceramic Tiles | A1 (Non-combustible) | Excellent fire resistance | Kitchens, bathrooms, high-fire-risk areas |

Plaque de plâtre | A2 (Non-combustible) | Good fire resistance | Wall and ceiling fireproofing |

- Polyuréthane: Polyurethane is generally B2 rated (combustible)but can be treated to achieve B1 rating (flame-retardant). It needs additional fire treatment for fire-sensitive applications.

- Bois: Wood is naturally B3 rated (flammable), and without proper fire treatment, it is highly combustible.

- Ceramic Tiles: Ceramic tiles have excellent fire resistance, with an A1 fire rating (non-combustible), making them ideal for kitchens, bathrooms, and other fire-prone areas.

- Plaque de plâtre: Gypsum board has good fire resistance with an A2 fire rating (non-combustible), suitable for walls and ceilings in fire-sensitive environments.

Price Comparison

Matériel | Price per Square Meter | Caractéristiques |

Polyuréthane | ¥50–150 | Price varies depending on density and application, suitable for high-performance insulation |

Bois | ¥100–500 | Price depends on wood type and treatment, requires maintenance |

Ceramic Tiles | ¥30–300 | Varies by brand and type, higher installation cost due to complexity |

Plaque de plâtre | ¥20–80 | Economical, but requires other materials for complete insulation |

- Polyuréthane: The price range for polyurethane foam varies from ¥50–150 per square meter, depending on its density and application. Although the initial cost may be higher, it provides significant cost savings over time due to its long lifespan and low maintenance.

- Bois: Wood is typically priced between ¥100–500 per square meter. While high-quality wood is expensive, it requires ongoing maintenance to prevent deterioration, which adds to its long-term cost.

- Ceramic Tiles: The cost of ceramic tiles ranges from ¥30–300 per square meter, with more expensive options typically offering better design or performance. The installation process is more complex, increasing the overall cost.

- Plaque de plâtre: Gypsum board is relatively inexpensive, typically priced between ¥20–80 per square meter, but additional materials like insulation may be needed, raising the overall cost.

Impact environnemental

Matériel | VOC Emissions | Recyclabilité | Certifications | Harmful Substances |

Polyuréthane | Low (modern PU often uses low-VOC formulas) | High (recyclable) | Meets international environmental standards | Non-toxic (high-quality PU) |

Bois | Moderate (depends on treatment and type) | High (wood can be recycled) | FSC-certified wood is environmentally friendly | May contain harmful chemicals if not treated properly |

Ceramic Tiles | Low (mostly inert) | High (recyclable) | Generally eco-friendly | Typically free of harmful substances |

Plaque de plâtre | Low (minimal VOC emissions) | High (can be recycled) | Meets environmental standards | Free of harmful substances (unless treated with additives) |

- Polyuréthane: Moderne polyuréthanematerials use low-VOC formulations and are largely recyclable. They are generally non toxique, meeting international environmental standards. However, the production of PU foam does consume energy, and the raw material may have a higher carbon footprint compared to some other materials.

- Bois: The environmental impact of boisvaries depending on the type and treatment process. Sustainable, FSC-certified wood is a highly renewable resource and can be recycled. However, poorly treated wood can release harmful chemicals and contribute to deforestation.

- Ceramic Tiles: Ceramic tiles are generally considered respectueux de l'environnementbecause they are made from natural materials and are recyclable. They do not emit harmful chemicals but can be energy-intensive to produce.

- Plaque de plâtre: Gypsum boardhas a low VOC emission and can be recyclé. It is considered an environmentally responsible choice when sourced responsibly, though it may contain additives that could be harmful in certain applications.

Conclusion

In conclusion, Polyuréthane stands out in terms of performance et environmental benefits, especially when it comes to sound insulation, isolation thermique, et durabilité. Its high performance in insulating, energy-saving, and noise-reduction aspects makes it suitable for modern, energy-efficient buildings. Though the initial cost may be higher, it can offer significant long-term savings.

However, Bois provides natural beauty and warmth but needs regular maintenance and treatment for fire resistance and moisture control. Ceramic Tiles are ideal for areas with high fire risk or where durability is paramount but are less effective in terms of insulation and soundproofing. Plaque de plâtre, while budget-friendly and eco-friendly, is better suited for basic construction needs and low-performance spaces.

Each material has its place in interior decoration depending on specific project needs such as budget, performance, et environmental considerations. Choosing the right material requires weighing the benefits and limitations of each according to the desired outcome of the project.