Ligne de production de semelles/semelles intérieures en PU

UREXCEED polyurethane sole/ insole production line offers high-efficiency, automated solutions for producing durable and customizable shoe soles and uppers, backed by advanced technology and comprehensive support services.

Ligne de production de semelles/semelles intérieures en PU

UREXCEED polyurethane sole/ insole production line is specifically designed for footwear manufacturers, providing efficient and precise production solutions. The line utilizes advanced high-pressure polyurethane foaming technology, enabling the rapid and stable production of various polyurethane shoe soles and uppers. We offer a complete set of customized equipment, including foaming machines, mixing systems, feeding devices, spraying equipment, and molds, making the entire production process more intelligent and automated.

In addition, UREXCEED sole/ insole production line ensures high product quality and stability while improving production efficiency. Whether it’s the hardness, elasticity of the shoe sole, or the comfort and durability of the upper, these parameters can be accurately adjusted according to customer needs. We also offer a one-stop service for raw material formulation development, equipment maintenance, and technical support, helping customers reduce production costs and improve market competitiveness.

Flux de processus d'UREXCEED PU Sole/Insole Production Line

Étape 1

Étape 2

Étape 3

Étape 4

Étape 5

Étape 6

Étape 7

À propos d'UREXCEED Ligne de production

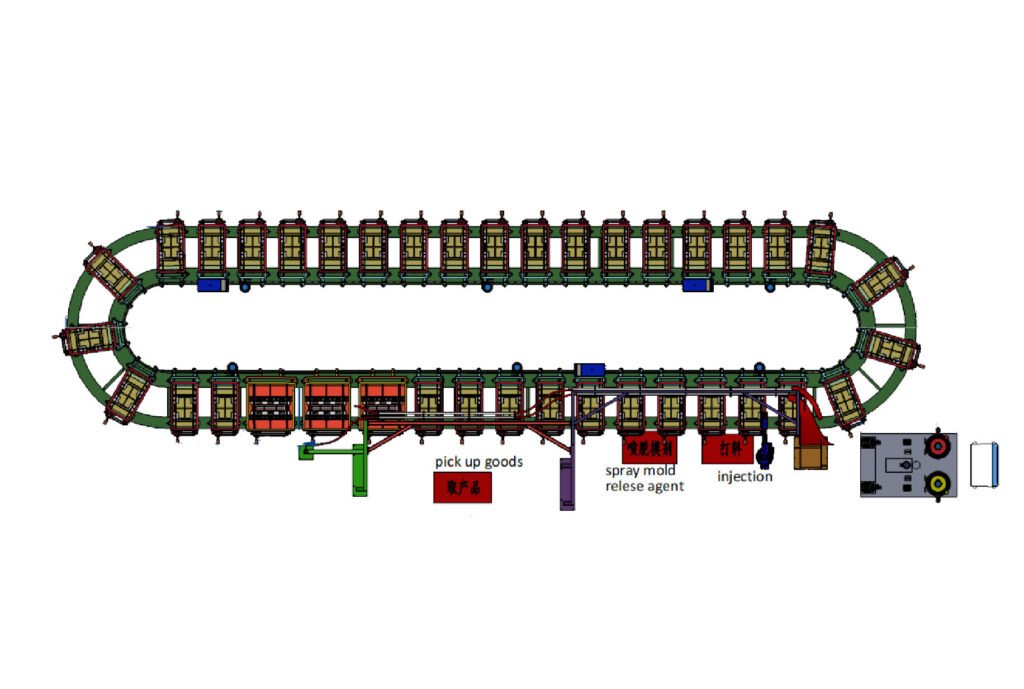

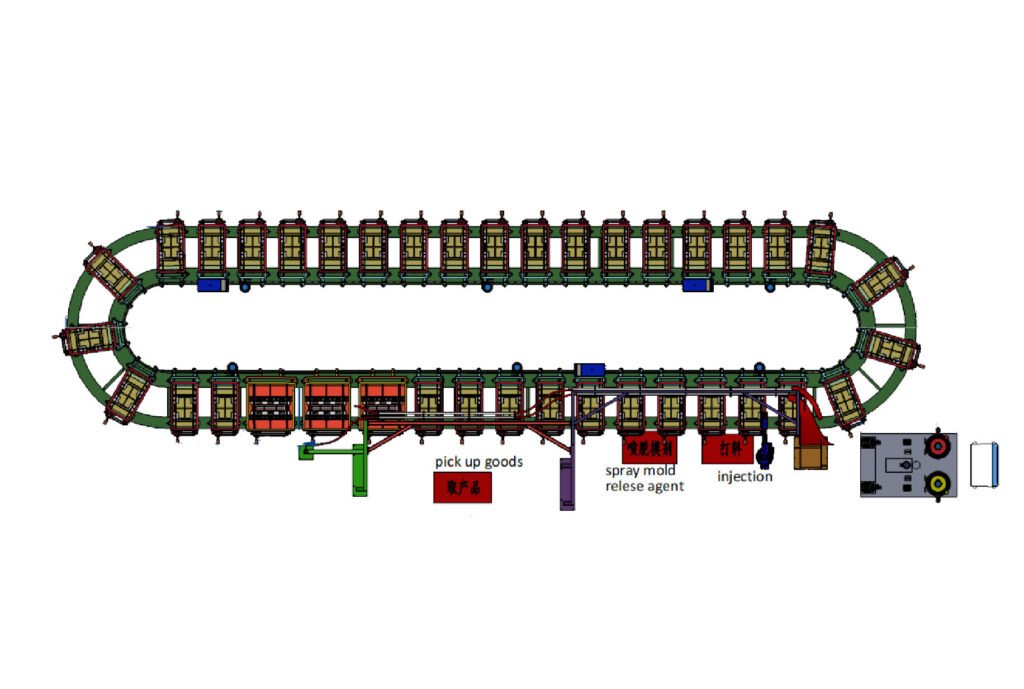

UREXCEED offer a variety of customizable production lines, including carousel lines, disk lines, and banana lines, designed to meet the specific needs of different manufacturing processes. Each production line type is engineered for maximum efficiency, flexibility, and scalability, enabling businesses to optimize their production while maintaining high-quality standards.

No matter the complexity or scale of your production needs, UREXCEED have the right line for you, ensuring maximum productivity and minimal downtime. UREXCEED comprehensive solutions are designed to improve efficiency, reduce operational costs, and enhance the overall manufacturing process.

Ligne de production de carrousels

Compact, rapide et hautement automatisé ; idéal pour une production standardisée à haut volume.

Ligne de production de carrousels

Compact, rapide et hautement automatisé ; idéal pour une production standardisée à haut volume.

Ligne de production rotative

Plus grand, plus flexible pour les conceptions complexes ; adapté aux volumes de production moyens à élevés.

Ligne de production rotative

Plus grand, plus flexible pour les conceptions complexes ; adapté aux volumes de production moyens à élevés.

Ligne de production de bananes

Peu encombrant, flexible pour les petites séries de production et les commandes personnalisées.

Ligne de production de bananes

Peu encombrant, flexible pour les petites séries de production et les commandes personnalisées.

Solution unique De la ligne de production de chaussures en PU

UREXCEED offer a comprehensive one-stop service for shoe production lines, providing customers with end-to-end solutions from raw materials to machinery, molds, and complete production lines. Whether it’s polyurethane shoe soles, uppers, or other shoe components, UREXCEED can tailor our services to meet specific customer needs. UREXCEED supply high-quality raw materials, including polyurethane foam, adhesives, and more, alongside advanced production equipment and automated production lines to ensure efficiency and precision throughout the manufacturing process.

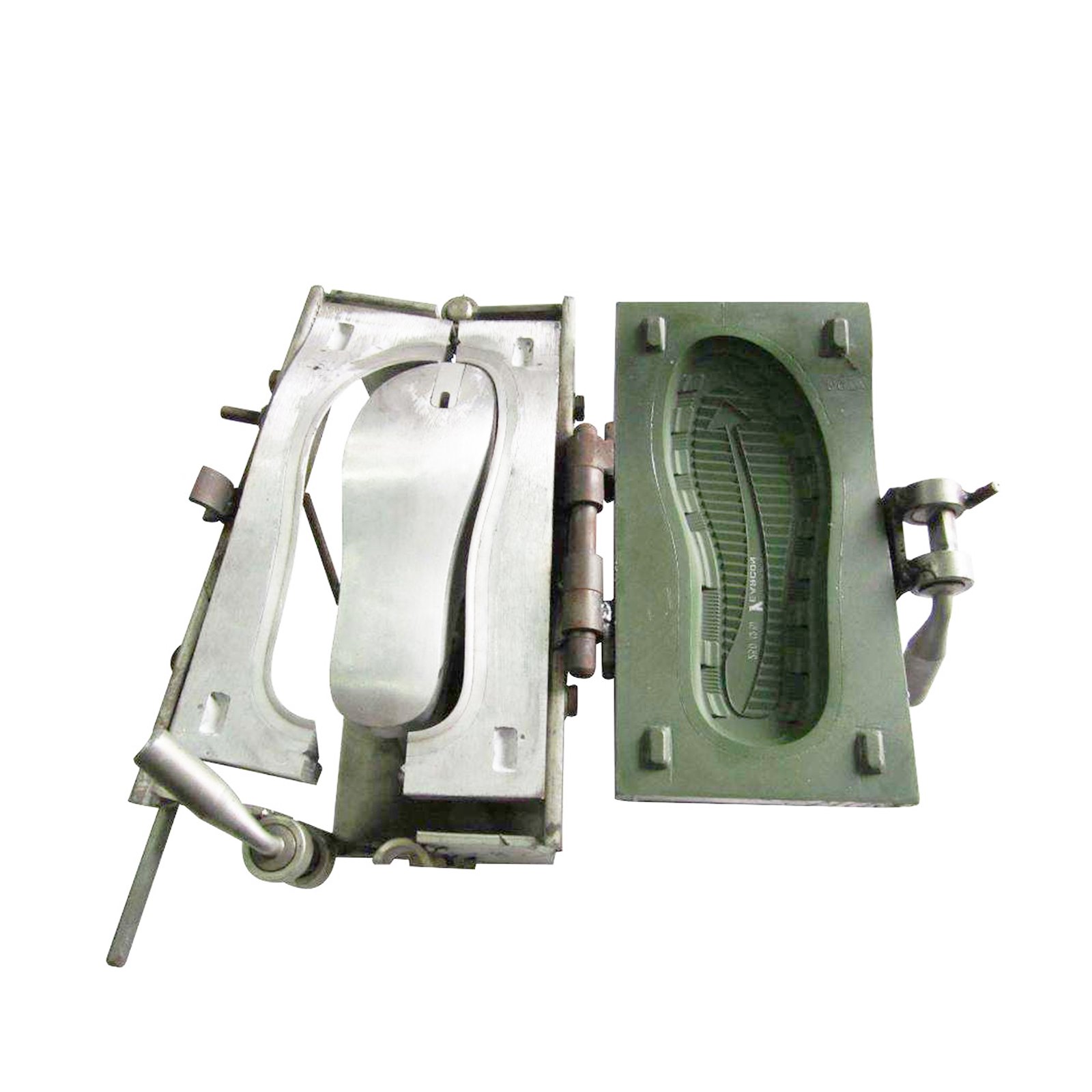

In terms of equipment, UREXCEED provide a full set of specialized machines, including foaming machines, mixing systems, and mold forming machines, ensuring seamless integration across all production stages. Additionally, UREXCEED can offer customized molds based on specific production requirements, helping customers improve efficiency and reduce production costs. UREXCEED PU shoes production line designs are flexible and can be tailored to fit factory spaces and meet individual production needs.

Through UREXCEED one-stop solution, customers can save time on procurement, reduce intermediary steps, lower overall operational costs, and ensure smooth production workflows. UREXCEED also provide comprehensive after-sales support, including equipment installation, technical training, and long-term maintenance services, ensuring stable and efficient production for our clients.

Machine à mousse

Moule

Matière première

Si vous souhaitez en savoir plus sur la ligne de production de semelles/semelles intérieures en PU, n'hésitez pas à nous contacter

Liste de lecture

Application d'UREXCEED PU Car Seat Production Line

Polyurethane soles are commonly found in sports, outdoor, medical and industrial workplaces. They are practical and comfortable and are one of the important materials for modern footwear manufacturing.

Sports Shoes And Casual Shoes:

Medical And Rehabilitation Shoes:

Anti-slip Shoes And Rain Boots:

Work Shoes And Safety Shoes:

Bon aperçu de la ligne de production de semelles/semelles intérieures en PU

UREXCEED polyurethane sole/ insole production line has received outstanding feedback from customers worldwide, praising its high efficiency, precision, and flexibility. Clients appreciate UREXCEED comprehensive service, from raw material supply to equipment installation and technical support, making the entire production process smoother and more cost-effective. Here are some of the positive reviews from satisfied customers:

La ligne de production est facile à utiliser et la qualité de nos chaussures s'est améliorée. Nous avons pu augmenter la production sans sacrifier la qualité. Excellent service !

Sarah Müller AllemagneLa ligne de production de chaussures en polyuréthane a considérablement amélioré notre efficacité de production. Les machines sont robustes et faciles à entretenir, et l'équipe a fourni un excellent service après-vente. Nous constatons des délais de production plus rapides et des résultats de meilleure qualité.

Ahmed Farsi Arabie SaouditeNous utilisons la ligne de production de chaussures en polyuréthane depuis plusieurs mois maintenant et nous ne pourrions être plus satisfaits. La mise en place a été rapide et l'équipe a fourni une formation approfondie. La ligne fonctionne sans problème et nous produisons désormais des chaussures de meilleure qualité et de meilleure qualité.

Li Wei ChineCertificat de la ligne de production de chaussures en PU UREXCEED

UREXCEED shoe production lines are built to meet the highest industry standards and are backed by internationally recognized certifications. We hold ISO 9001:2015 for quality management, ensuring consistent performance and reliability; ISO 13485 for precision and safety in manufacturing processes; and IATF 16949:2016, a global standard for quality in the automotive industry, demonstrating our expertise in high-quality production equipment. Additionally, we provide material certification, process and batch traceability, full-size reports, and inspection certificates, ensuring every aspect of the production line meets stringent global requirements. These certifications guarantee that our solutions deliver unmatched quality and compliance for customers worldwide.

Nous sommes très satisfaits de la ligne de production de chaussures en polyuréthane. Le système est efficace et fiable, et le support est excellent. La production s'est améliorée et les coûts ont diminué. Je recommande vivement !

Juan Pérez Mexique