Ligne de production de sièges auto de haute qualité

Ligne de production de sièges auto

UREXCEED polyurethane automotive seat production line is designed for efficient and high-precision molding of automotive seats, meeting the stringent requirements of modern automotive industries for comfort, safety, and environmental standards. The full production line includes a machine à mousser, moules et cadres de moules, intégrés à des systèmes de contrôle avancés pour garantir les normes de qualité les plus élevées tout au long du processus de production.

Flux de processus d'UREXCEED PU Car Seat Production Line

Étape 1

Étape 2

Étape 3

Étape 4

Étape 5

À propos d'UREXCEED Ligne de production de sièges auto

UREXCEED offers a wide range of customizable lines, including rotary lines, carousel lines and banana lines, designed to meet the specific needs of different manufacturing processes. Regardless of the complexity or scale of your production needs, UREXCEED can provide you with the right line to ensure maximum productivity and minimize downtime. Our comprehensive solutions are designed to increase efficiency, reduce operating costs and enhance the overall manufacturing process.

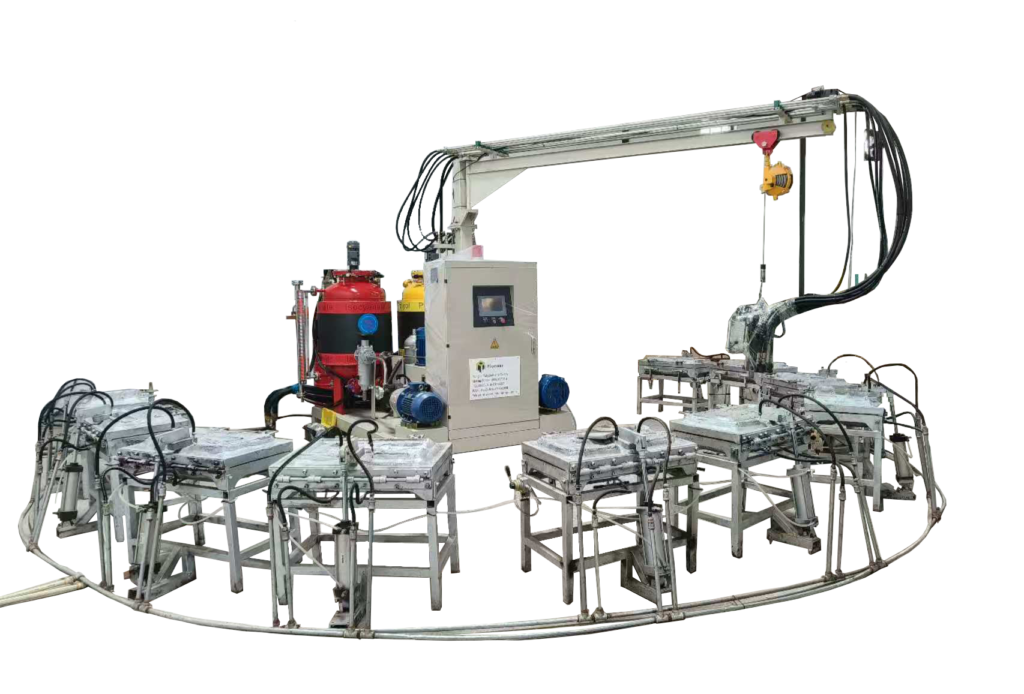

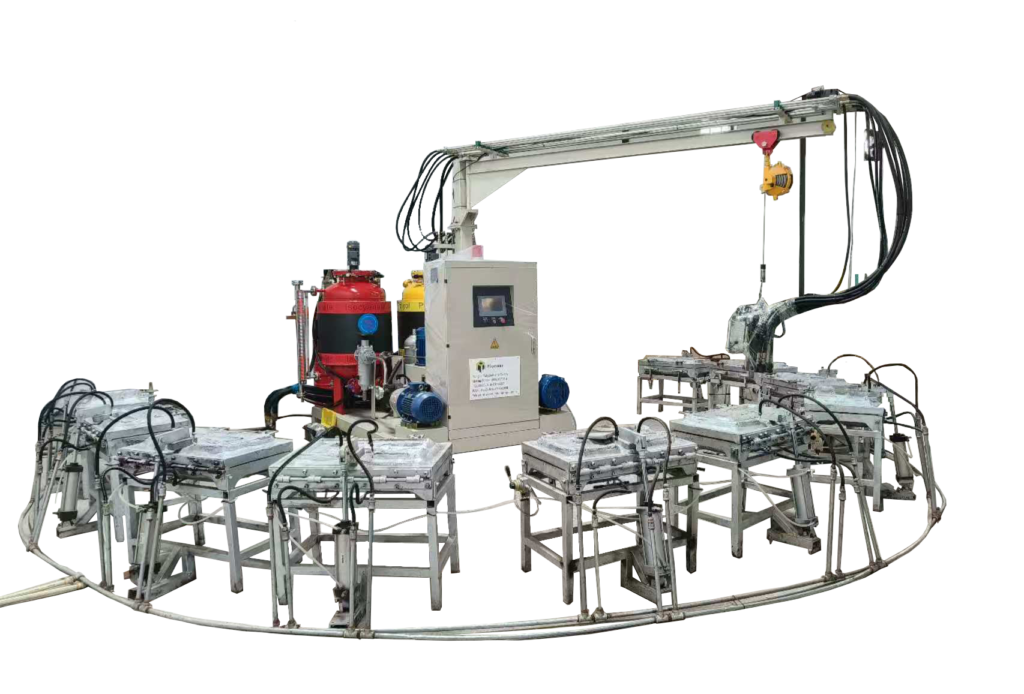

Ligne de production de carrousels

Idéal pour une production simple à cycle court avec une structure simple

Ligne de production de carrousels

Idéal pour une production simple à cycle court avec une structure simple

Applications : La ligne de production UREXCEED est adaptée aux processus de fabrication relativement simples, tels que le revêtement, le pressage ou d'autres opérations. Elle est généralement utilisée pour la production en petites séries ou pour des produits ayant des exigences de processus spécifiques.

Caractéristiques : Compacte et simple, la ligne de production à carrousel est idéale pour la fabrication de produits uniques ou pour les besoins de production à petite échelle et à cycle court.

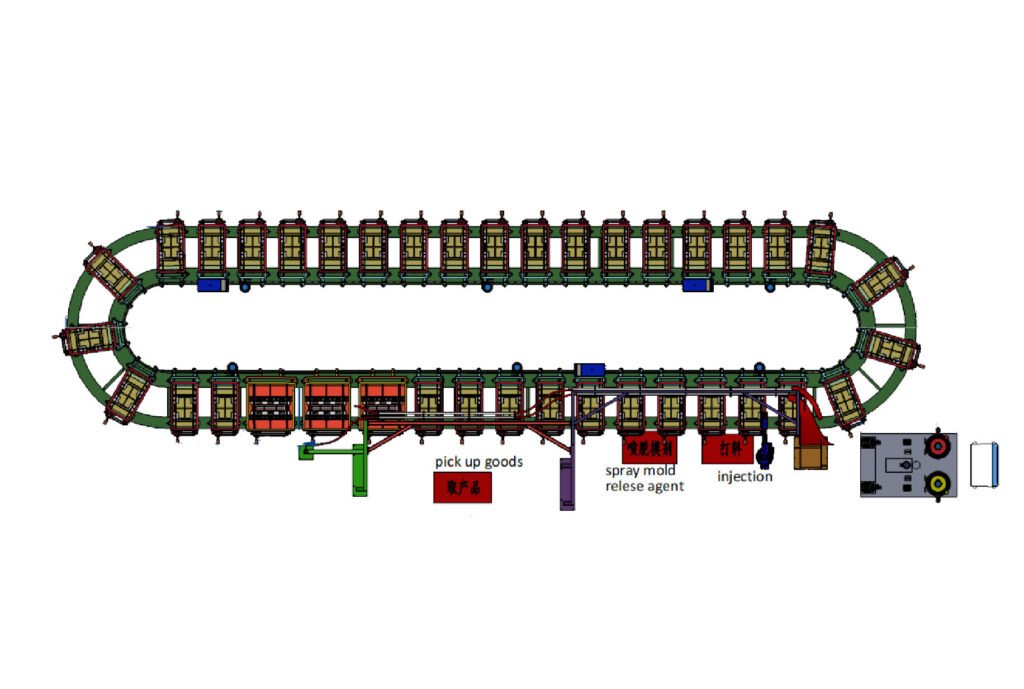

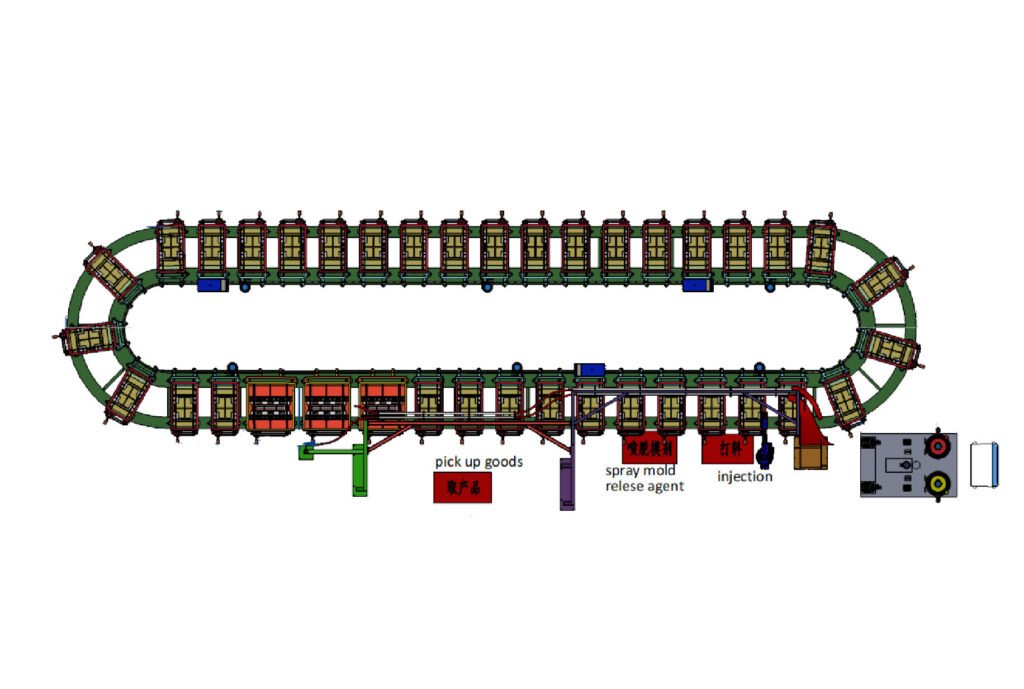

Ligne de production rotative

Convient à la production automatisée à grande échelle et en plusieurs étapes.

Ligne de production rotative

Convient à la production automatisée à grande échelle et en plusieurs étapes.

Applications : Les lignes de production rotatives UREXCEED sont souvent utilisées pour les produits nécessitant plusieurs processus et une production continue. Elles sont particulièrement efficaces dans la production de masse et les environnements hautement automatisés.

Caractéristiques : Grâce à leur grande flexibilité, les lignes de production rotatives peuvent être configurées avec plusieurs postes de travail. Elles sont particulièrement adaptées aux tâches de production à long terme et à haut rendement, impliquant souvent des produits plus complexes.

Ligne de production de bananes

Conçu pour les produits nécessitant des formes spécialisées ou des pistes de traitement courbes, offrant une grande flexibilité.

Ligne de production de bananes

Conçu pour les produits nécessitant des formes spécialisées ou des pistes de traitement courbes, offrant une grande flexibilité.

Applications : Ce type de ligne de production est utilisé pour les processus nécessitant des pistes courbes ou des formes spécifiques. Elle est particulièrement adaptée à la manipulation de matériaux flexibles ou à la fabrication de produits aux formes complexes.

Caractéristiques : Connue pour son adaptabilité, la ligne de production de bananes peut gérer des pièces aux formes ou angles uniques, ce qui la rend idéale pour les produits nécessitant un traitement à angle variable ou à forme spécifique.

Solution unique De la ligne de production de sièges d'auto

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

Machine à mousse

Moule

Mold Temperature Control Machine

Matière première

Contactez-nous pour un devis complet

Les machines UREXCEED sont 30% moins chères que les machines européennes

FAQ De la ligne de production de sièges d'auto

Uniform foaming is achieved by precisely controlling the raw material mix ratios, injection pressure, and mold temperature. The mold temperature controller plays a key role in maintaining consistent heat distribution, ensuring that the foam expands evenly and cures uniformly.

The mold temperature machine (or mold temperature controller) heats or cools the mold to maintain a constant temperature. This is critical for controlling the foaming reaction, ensuring proper material flow, and ultimately achieving a high-quality, consistent product.

Regular maintenance is essential. It includes:

- Routine inspections and cleaning of molds, nozzles, and mixing heads.

- Calibration of dosing pumps and monitoring of injection pressure.

- Preventive maintenance schedules to reduce downtime and maintain optimal production efficiency.

In case of issues, check the following:

- Raw Material Mix: Ensure the correct ratios of polyol and isocyanate.

- Injection Parameters: Verify that the injection pressure and speed are set correctly.

- Mold Temperature: Confirm that the mold is at the required temperature.

- Release Agent Application: Ensure even application to prevent sticking and surface defects.

Safety and environmental compliance are ensured by:

- Adhering to strict operational protocols and safety guidelines.

- Using eco-friendly raw materials and release agents.

- Implementing proper ventilation and waste management systems to control emissions and protect workers.

Operators receive comprehensive training that includes:

- Detailed operation manuals and on-site training sessions.

- Remote technical support and troubleshooting assistance.

- Continuous updates on best practices to ensure efficient and safe production.

Liste de lecture

Transaction Case Of UREXCEED PU Car Seat Production Line

Good Review Of Car Seat Production Line

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

La ligne de production d'UREXCEED est fiable et efficace, ce qui augmente la production et réduit les temps d'arrêt. Nous sommes très satisfaits de l'équipement et du support.

Sarah Müller AllemagneNous sommes très satisfaits de la ligne de production de sièges d'UREXCEED. Elle a amélioré l'efficacité et assuré une qualité élevée. L'équipe a fourni un excellent support technique. Hautement recommandé !

Juan Pérez MexiqueNotre efficacité de production a augmenté de 30% grâce à la ligne de production de sièges UREXCEED. Les fonctions intelligentes ont réduit les erreurs et le service était excellent. Très satisfait !

Abdul Aziz Émirats arabes unisLa ligne de production d'UREXCEED est stable, efficace et hautement automatisée. Elle minimise les erreurs et augmente la production. Je recommande vivement ! »

Carlos Mendoza EspagneNous avons obtenu d'excellents résultats avec cette machine à mousse pulvérisée. Elle produit un revêtement uniforme et est facile à contrôler.

La machine d'enduction fonctionne parfaitement, en appliquant à chaque fois la bonne quantité de colle. C'est un excellent ajout à notre ligne de production.

Eliot Davis Directeur des opérations

A Mexican automotive parts manufacturer sought to improve seat production efficiency and ensure stable product quality. They required a highly efficient and automated polyurethane car seat production line, including a high-pressure polyurethane foaming machine, mold temperature controller, seat molds, and a production line. After multiple discussions, we provided a customized, energy-efficient solution, optimizing key processes such as mold heating, release agent spraying, material injection, and foaming. The client was impressed by our equipment stability, uniform foaming, and one-stop service, leading to a successful order. After installation, we offered remote technical support and on-site training to ensure smooth production. The line is now fully operational, delivering high product yield and helping the client enhance efficiency while reducing costs.

Mexique