Lini Produksi Kursi Mobil Berkualitas Tinggi

Lini Produksi Kursi Mobil

UREXCEED polyurethane automotive seat production line is designed for efficient and high-precision molding of automotive seats, meeting the stringent requirements of modern automotive industries for comfort, safety, and environmental standards. The full production line includes a mesin pembuat busa, cetakan, dan rangka cetakan, terintegrasi dengan sistem kontrol canggih untuk memastikan standar kualitas tertinggi di seluruh proses produksi.

Aliran Proses UREXCEED Lini Produksi Kursi Mobil PU

Langkah 1

Langkah 2

Langkah 3

Langkah 4

Langkah 5

Tentang UREXCEED Lini Produksi Kursi Mobil

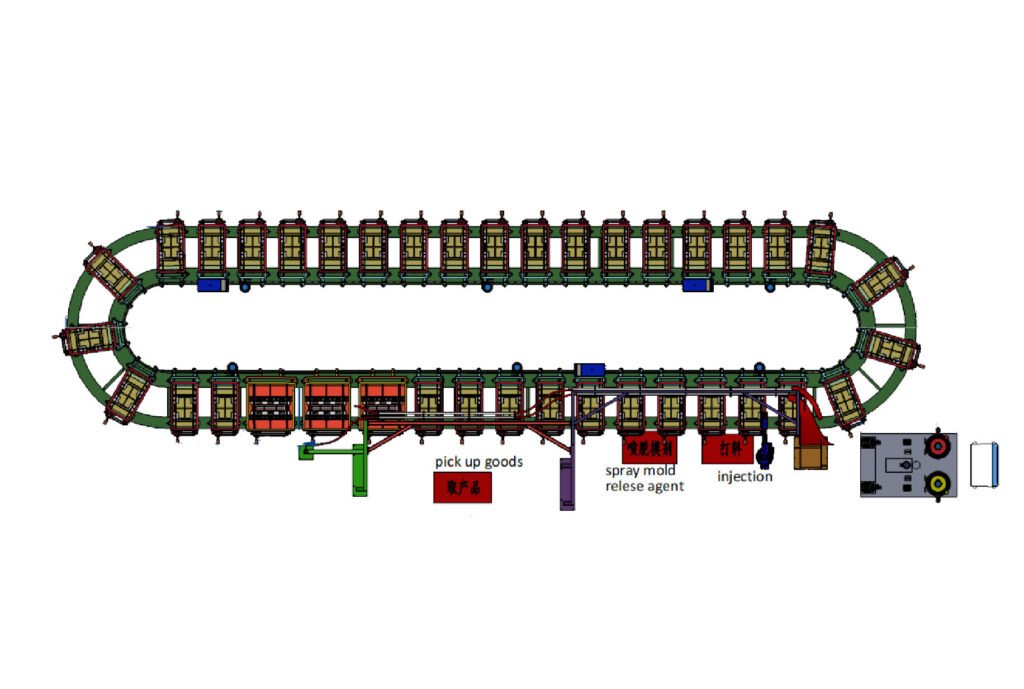

UREXCEED offers a wide range of customizable lines, including rotary lines, carousel lines and banana lines, designed to meet the specific needs of different manufacturing processes. Regardless of the complexity or scale of your production needs, UREXCEED can provide you with the right line to ensure maximum productivity and minimize downtime. Our comprehensive solutions are designed to increase efficiency, reduce operating costs and enhance the overall manufacturing process.

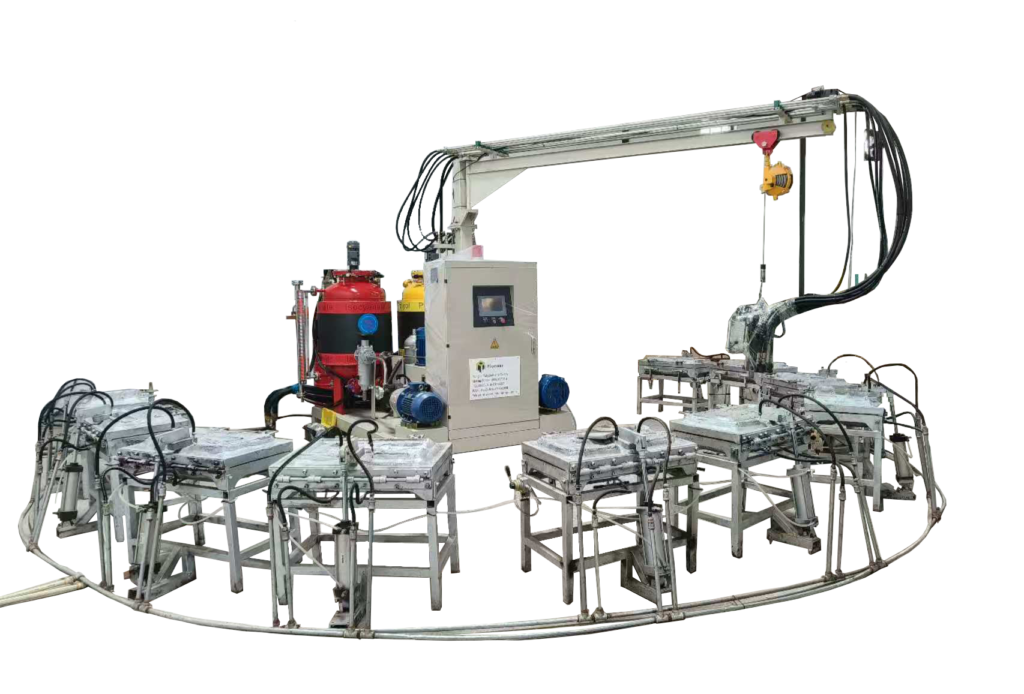

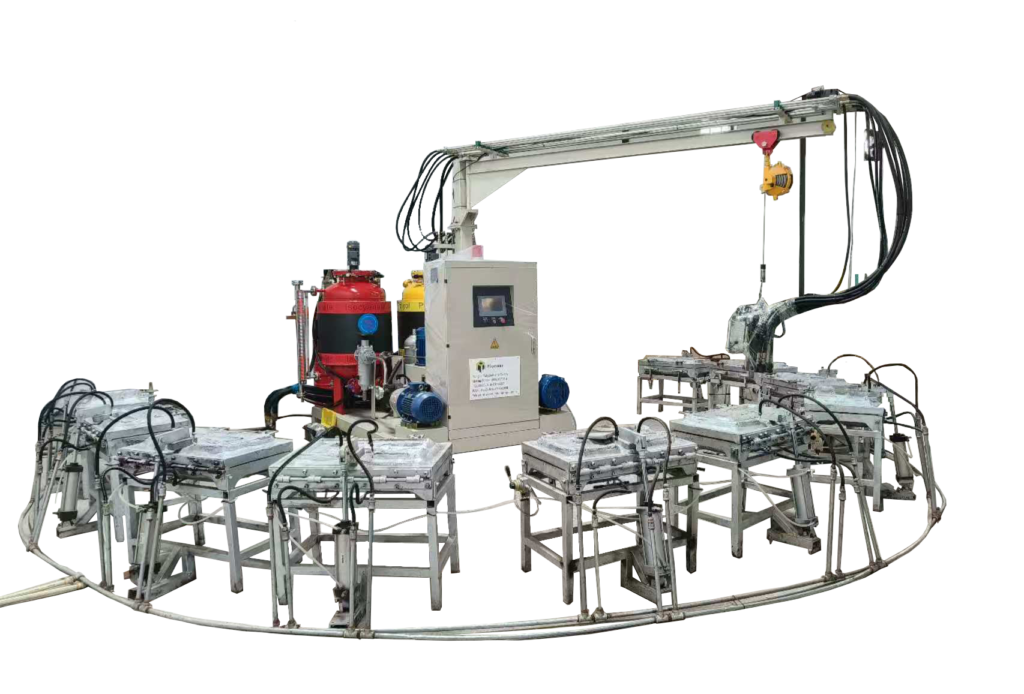

Lini Produksi Korsel

Paling cocok untuk produksi siklus pendek yang sederhana dengan struktur yang mudah dipahami

Lini Produksi Korsel

Paling cocok untuk produksi siklus pendek yang sederhana dengan struktur yang mudah dipahami

Aplikasi: Lini produksi UREXCEED cocok untuk proses manufaktur yang relatif sederhana, seperti pelapisan, pengepresan, atau operasi lainnya. Lini ini umumnya digunakan untuk produksi skala kecil atau produk dengan persyaratan proses tertentu.

Fitur: Kompak dan mudah digunakan, lini produksi karusel ideal untuk produksi produk tunggal atau kebutuhan produksi skala kecil dan siklus pendek.

Lini Produksi Rotary

Cocok untuk produksi otomatis berskala besar dan multi-langkah.

Aplikasi: Lini produksi putar UREXCEED sering digunakan untuk produk yang memerlukan beberapa proses dan produksi berkelanjutan. Lini ini sangat efektif dalam produksi massal dan lingkungan yang sangat otomatis.

Fitur: Dengan fleksibilitas tinggi, lini produksi putar dapat dikonfigurasikan dengan beberapa stasiun kerja. Lini ini sangat cocok untuk tugas produksi jangka panjang dengan efisiensi tinggi, yang sering kali melibatkan produk yang lebih kompleks.

Lini Produksi Pisang

Dirancang untuk produk yang memerlukan bentuk khusus atau jalur pemrosesan melengkung, menawarkan fleksibilitas tinggi.

Lini Produksi Pisang

Dirancang untuk produk yang memerlukan bentuk khusus atau jalur pemrosesan melengkung, menawarkan fleksibilitas tinggi.

Aplikasi: Jenis lini produksi ini digunakan untuk proses yang memerlukan lintasan lengkung atau bentuk tertentu. Lini ini sangat cocok untuk menangani material fleksibel atau memproduksi produk dengan bentuk yang rumit.

Fitur: Dikenal karena kemampuan beradaptasinya, lini produksi pisang dapat menangani benda kerja dengan bentuk atau sudut yang unik, membuatnya ideal untuk produk yang memerlukan pemrosesan sudut variabel atau bentuk khusus.

Solusi Satu Atap Dari Lini Produksi Kursi Mobil

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

Mesin Busa

Cetakan

Mold Temperature Control Machine

Bahan mentah

Hubungi kami untuk penawaran lengkap

Mesin UREXCEED 30% lebih murah dibandingkan mesin Eropa

Tanya Jawab Umum Dari Lini Produksi Kursi Mobil

Uniform foaming is achieved by precisely controlling the raw material mix ratios, injection pressure, and mold temperature. The mold temperature controller plays a key role in maintaining consistent heat distribution, ensuring that the foam expands evenly and cures uniformly.

The mold temperature machine (or mold temperature controller) heats or cools the mold to maintain a constant temperature. This is critical for controlling the foaming reaction, ensuring proper material flow, and ultimately achieving a high-quality, consistent product.

Regular maintenance is essential. It includes:

- Routine inspections and cleaning of molds, nozzles, and mixing heads.

- Calibration of dosing pumps and monitoring of injection pressure.

- Preventive maintenance schedules to reduce downtime and maintain optimal production efficiency.

In case of issues, check the following:

- Raw Material Mix: Ensure the correct ratios of polyol and isocyanate.

- Injection Parameters: Verify that the injection pressure and speed are set correctly.

- Mold Temperature: Confirm that the mold is at the required temperature.

- Release Agent Application: Ensure even application to prevent sticking and surface defects.

Safety and environmental compliance are ensured by:

- Adhering to strict operational protocols and safety guidelines.

- Using eco-friendly raw materials and release agents.

- Implementing proper ventilation and waste management systems to control emissions and protect workers.

Operators receive comprehensive training that includes:

- Detailed operation manuals and on-site training sessions.

- Remote technical support and troubleshooting assistance.

- Continuous updates on best practices to ensure efficient and safe production.

Daftar Putar

Transaction Case Of UREXCEED PU Car Seat Production Line

Good Review Of Car Seat Production Line

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

Lini produksi UREXCEED dapat diandalkan dan efisien, meningkatkan hasil produksi dan mengurangi waktu henti. Kami sangat puas dengan peralatan dan dukungan yang diberikan.

Sarah Muller JermanKami sangat puas dengan lini produksi kursi UREXCEED. Lini ini meningkatkan efisiensi dan memastikan kualitas tinggi. Tim menyediakan dukungan teknis yang hebat. Sangat direkomendasikan!

Juan Perez MeksikoEfisiensi produksi kami meningkat sebesar 30% dengan lini produksi kursi UREXCEED. Fitur-fitur cerdas mengurangi kesalahan, dan layanannya sangat baik. Sangat puas!

Abdul Aziz Uni Emirat ArabLini produksi UREXCEED stabil, efisien, dan sangat otomatis. Lini ini meminimalkan kesalahan dan meningkatkan produksi. Sangat direkomendasikan!"

Carlos Mendoza SpanyolKami telah melihat hasil yang luar biasa dengan mesin busa semprot ini. Mesin ini menghasilkan lapisan yang merata dan mudah dikontrol.

Mesin pelapis bekerja dengan lancar, mengaplikasikan lem dalam jumlah yang tepat setiap saat. Ini merupakan tambahan yang bagus untuk lini produksi kami.

Eliot Davis Direktur Operasional

A Mexican automotive parts manufacturer sought to improve seat production efficiency and ensure stable product quality. They required a highly efficient and automated polyurethane car seat production line, including a high-pressure polyurethane foaming machine, mold temperature controller, seat molds, and a production line. After multiple discussions, we provided a customized, energy-efficient solution, optimizing key processes such as mold heating, release agent spraying, material injection, and foaming. The client was impressed by our equipment stability, uniform foaming, and one-stop service, leading to a successful order. After installation, we offered remote technical support and on-site training to ensure smooth production. The line is now fully operational, delivering high product yield and helping the client enhance efficiency while reducing costs.

Meksiko