Lini Produksi Sol/Sol Dalam PU

UREXCEED polyurethane sole/ insole production line offers high-efficiency, automated solutions for producing durable and customizable shoe soles and uppers, backed by advanced technology and comprehensive support services.

Lini Produksi Sol/Sol Dalam PU

UREXCEED polyurethane sole/ insole production line is specifically designed for footwear manufacturers, providing efficient and precise production solutions. The line utilizes advanced high-pressure polyurethane foaming technology, enabling the rapid and stable production of various polyurethane shoe soles and uppers. We offer a complete set of customized equipment, including foaming machines, mixing systems, feeding devices, spraying equipment, and molds, making the entire production process more intelligent and automated.

In addition, UREXCEED sole/ insole production line ensures high product quality and stability while improving production efficiency. Whether it’s the hardness, elasticity of the shoe sole, or the comfort and durability of the upper, these parameters can be accurately adjusted according to customer needs. We also offer a one-stop service for raw material formulation development, equipment maintenance, and technical support, helping customers reduce production costs and improve market competitiveness.

Aliran Proses UREXCEED Lini Produksi Sol/Sol Dalam PU

Langkah 1

Langkah 2

Langkah 3

Langkah 4

Langkah 5

Langkah 6

Langkah 7

Tentang UREXCEED Jalur Produksi

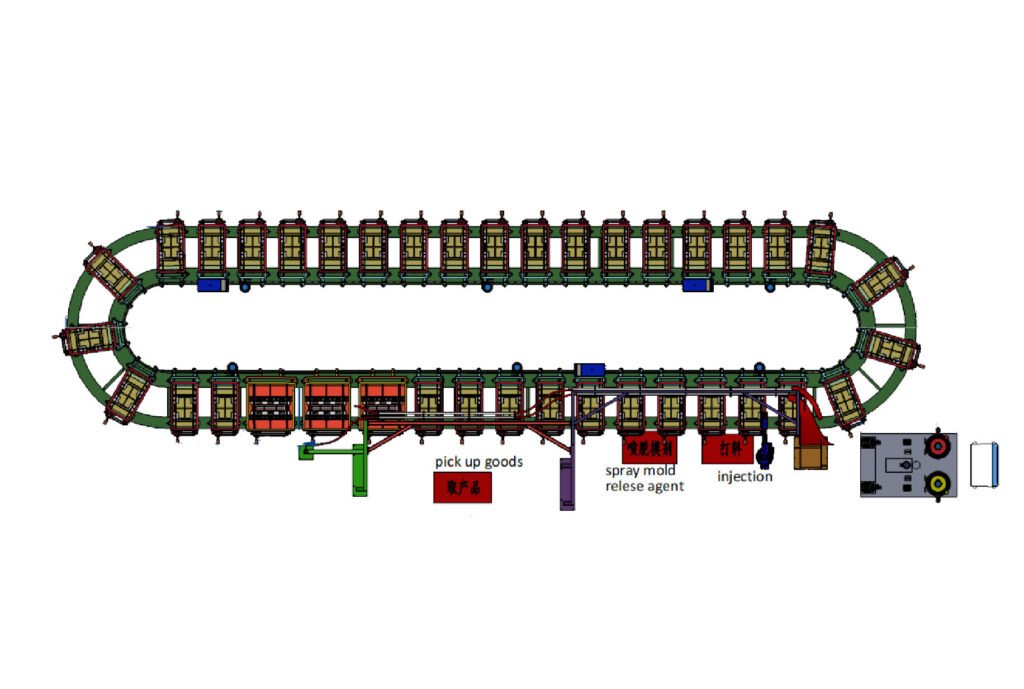

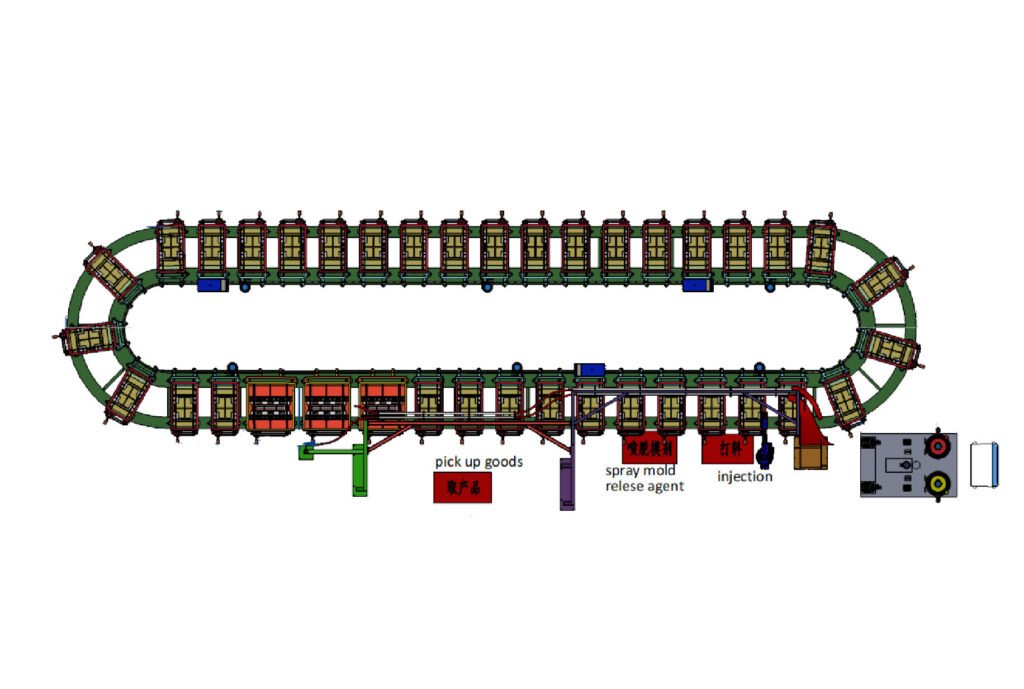

UREXCEED offer a variety of customizable production lines, including carousel lines, disk lines, and banana lines, designed to meet the specific needs of different manufacturing processes. Each production line type is engineered for maximum efficiency, flexibility, and scalability, enabling businesses to optimize their production while maintaining high-quality standards.

No matter the complexity or scale of your production needs, UREXCEED have the right line for you, ensuring maximum productivity and minimal downtime. UREXCEED comprehensive solutions are designed to improve efficiency, reduce operational costs, and enhance the overall manufacturing process.

Lini Produksi Korsel

Kompak, cepat, dan sangat otomatis; terbaik untuk produksi bervolume tinggi dan terstandarisasi.

Lini Produksi Korsel

Kompak, cepat, dan sangat otomatis; terbaik untuk produksi bervolume tinggi dan terstandarisasi.

Lini Produksi Rotary

Lebih besar, lebih fleksibel untuk desain yang rumit; cocok untuk volume produksi sedang hingga tinggi.

Lini Produksi Rotary

Lebih besar, lebih fleksibel untuk desain yang rumit; cocok untuk volume produksi sedang hingga tinggi.

Lini Produksi Pisang

Hemat-ruang, fleksibel untuk produksi skala kecil dan pesanan khusus.

Solusi Satu Atap Lini Produksi Sepatu PU

UREXCEED offer a comprehensive one-stop service for shoe production lines, providing customers with end-to-end solutions from raw materials to machinery, molds, and complete production lines. Whether it’s polyurethane shoe soles, uppers, or other shoe components, UREXCEED can tailor our services to meet specific customer needs. UREXCEED supply high-quality raw materials, including polyurethane foam, adhesives, and more, alongside advanced production equipment and automated production lines to ensure efficiency and precision throughout the manufacturing process.

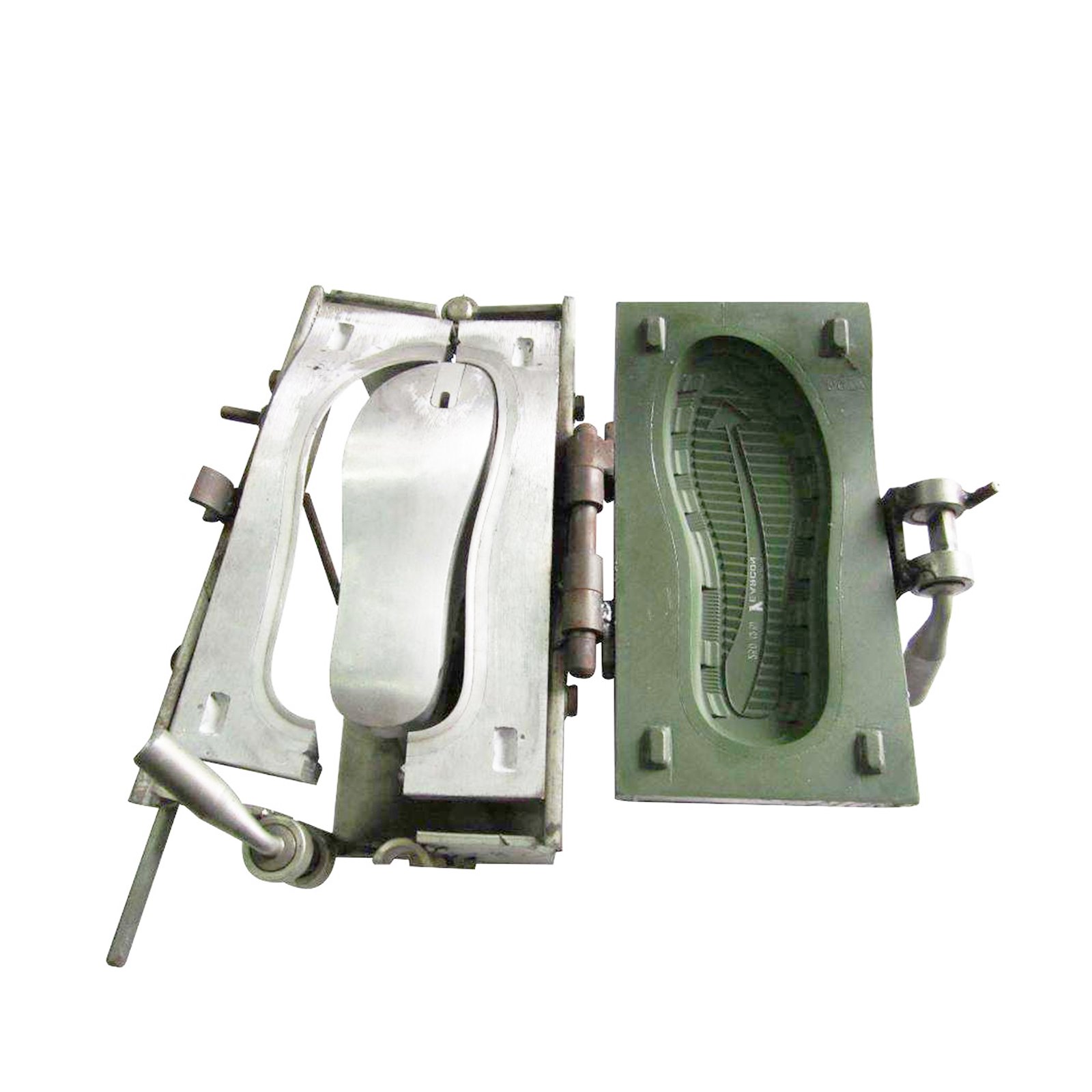

In terms of equipment, UREXCEED provide a full set of specialized machines, including foaming machines, mixing systems, and mold forming machines, ensuring seamless integration across all production stages. Additionally, UREXCEED can offer customized molds based on specific production requirements, helping customers improve efficiency and reduce production costs. UREXCEED PU shoes production line designs are flexible and can be tailored to fit factory spaces and meet individual production needs.

Through UREXCEED one-stop solution, customers can save time on procurement, reduce intermediary steps, lower overall operational costs, and ensure smooth production workflows. UREXCEED also provide comprehensive after-sales support, including equipment installation, technical training, and long-term maintenance services, ensuring stable and efficient production for our clients.

Mesin Busa

Cetakan

Bahan mentah

Jika Anda ingin tahu lebih banyak tentang lini produksi sol pu / sol dalam, jangan ragu untuk menghubungi kami

Daftar Putar

Aplikasi UREXCEED Lini Produksi Kursi Mobil PU

Polyurethane soles are commonly found in sports, outdoor, medical and industrial workplaces. They are practical and comfortable and are one of the important materials for modern footwear manufacturing.

Sports Shoes And Casual Shoes:

Medical And Rehabilitation Shoes:

Anti-slip Shoes And Rain Boots:

Work Shoes And Safety Shoes:

Ulasan Bagus Tentang Lini Produksi Sol/Sol Dalam PU

UREXCEED polyurethane sole/ insole production line has received outstanding feedback from customers worldwide, praising its high efficiency, precision, and flexibility. Clients appreciate UREXCEED comprehensive service, from raw material supply to equipment installation and technical support, making the entire production process smoother and more cost-effective. Here are some of the positive reviews from satisfied customers:

Lini produksi mudah dioperasikan, dan kualitas sepatu kami pun meningkat. Kami mampu meningkatkan produksi tanpa mengorbankan kualitas. Layanan yang hebat!

Sarah Muller JermanLini produksi sepatu poliuretan telah meningkatkan efisiensi produksi kami secara signifikan. Mesin-mesinnya kuat dan mudah dirawat, dan tim kami memberikan layanan purnajual yang sangat baik. Kami melihat waktu produksi yang lebih cepat dan hasil yang lebih berkualitas.

Ahmad Farisi Arab SaudiKami telah menggunakan lini produksi sepatu poliuretan selama beberapa bulan, dan kami sangat puas. Proses pemasangannya cepat, dan tim memberikan pelatihan menyeluruh. Lini produksi berjalan lancar, dan kini kami memproduksi sepatu dengan kualitas dan konsistensi yang lebih baik."

Li Wei CinaSertifikat Lini Produksi Sepatu UREXCEED PU

UREXCEED shoe production lines are built to meet the highest industry standards and are backed by internationally recognized certifications. We hold ISO 9001:2015 for quality management, ensuring consistent performance and reliability; ISO 13485 for precision and safety in manufacturing processes; and IATF 16949:2016, a global standard for quality in the automotive industry, demonstrating our expertise in high-quality production equipment. Additionally, we provide material certification, process and batch traceability, full-size reports, and inspection certificates, ensuring every aspect of the production line meets stringent global requirements. These certifications guarantee that our solutions deliver unmatched quality and compliance for customers worldwide.

Kami sangat senang dengan lini produksi sepatu poliuretan. Sistemnya efisien dan andal, dan dukungannya luar biasa. Produksi telah meningkat, dan biaya telah turun. Sangat direkomendasikan!

Juan Perez Meksiko