Mesin Semprot Busa Poliuretan

- After rigorous testing, the spray foam machine guarantees zero downtime, ensuring smooth and uninterrupted operation.

- The spray foam machine is designed to be lightweight and portable, making it suitable for mobile applications and on-site use.

- We offer a complete solution, from equipment to raw materials, ensuring a seamless production process for our customers.

Classification Of UREXCEED PU Foam Spray Machine

JYYJ-3D Polyurethane Spray Machine

| Driven mode | Pneumatic |

| model | JYYJ-3D |

| Power supply | Single phase 220V 50Hz |

| Heating power | 7.5KW |

| Raw output | 2~12 kg/min |

JYYJ-H600 PU Foam Spray Machine

| Drive mode | Hydraulic drive |

| model | JYYJ-H600 |

| Power supply | 3-phase 4-wires 380V 50HZ |

| Heating power | 22KW |

| Raw material output | 2~12 kg/min |

JYYJ-H800 Polyurethane Spray Foam Equipment

| Drive mode | Hydraulic drive |

| model | JYYJ-H800 |

| Power supply | 3-phase 4-wires 380V 50HZ |

| Heating power | 30KW |

| Raw material output | 2~12 kg/min |

JYYJ-Q300 Foam Insulation Machine

| Drive mode | Pneumatic |

| model | JYYJ-Q300 |

| Power supply | 380V 50HZ |

| Heating power | 15KW |

| Raw material output | 2~10 kg/min |

JYYJ-H-V6 Spray Foam Insulation Machine

| Drive mode | Hydraulic drive |

| model | JYYJ-H-V6 |

| power supply | Three-phase three-wire 380V |

| heating power | 22KWV |

| Raw material output | 2-10KG/Min |

JYYJ-A-V3 Foam Insulation Equipment

| Drive mode | Pneumatic drive |

| model | JYYJ-A-V3 |

| power supply | 380V 50Hz |

| heating power | 9.5KW |

| Raw material output | 2-10KG/Min |

Want to know more about specification of PU foam spray machine?

Transfer Pump

Power Cylinder

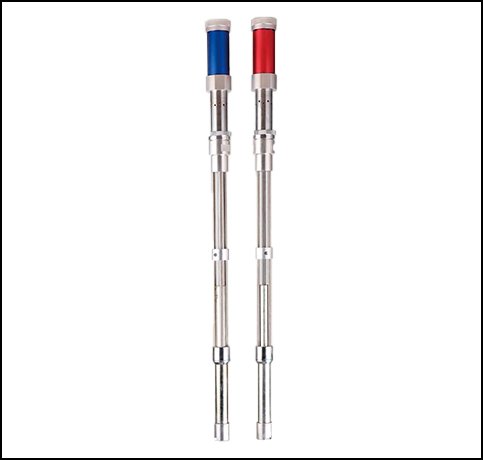

Spray Gun

Working Principle Of UREXCEED PU Foam Spray Machine

01 Material Supply

02 High-Pressure Delivery

03 Material Mixing

Inside the spray nozzle, the polyol and isocyanate are mixed under high shear. As the materials react chemically, they produce foam that rapidly expands. The mixing system within the nozzle ensures uniform blending of the components, preventing uneven foaming or air bubbles.

04 Spraying and Expansion

The mixed foam is sprayed onto the desired surface through the spray gun. Upon contact with the surface, the foam begins to expand immediately, forming an even layer. The foam cures within minutes, forming a solid, airtight, and thermal insulating layer.

05 Curing and Molding

Once sprayed, the foam material cures and solidifies, forming a durable, seamless insulation or protective layer. The foam provides excellent heat insulation, moisture resistance, and long-term durability, making it ideal for applications in construction, cold storage, automotive, and other industries.

FAQs Of UREXCEED PU Spray Foam Machine

We currently have two types of pneumatic and hydraulic, 220v and 380v. Recently, a Mexican customer requested 110V 400v, and we are also working on it.

Calculate based on the density of the raw material and the thickness of the spray coating. For example, the density is 30kg/m3 and the thickness is 7cm.

The material pump extracts the raw materials into the spraying machine, heats them to the required temperature, then transports them to the spray gun through the heating pipe, mixes them thoroughly in the spray gun, and then sprays them out.

A: The pipeline and power supply from the host computer to the gun are already connected.

The following checks should be carried out before operation:

1. All joints from the main unit to the gun do not leak air or material,

2. Be sure to separate the A and B materials in the entire input pipeline from the pump to the gun to avoid paralysis of the entire system.

3. There should be safety grounding and leakage protection.

4. When the equipment stops working, the heating system should be turned off in time and the power supply should be cut off to avoid deterioration in foaming quality caused by excessive heating time.

The pneumatic model is at least 0.9Mpa/min, and the hydraulic model is only 0.5Mpa/min.

Optimum temperature 10-25℃

Generally, as long as the sealing ring is replaced, we will give you some in the tool box of the following machine.

·The temperature of the fresh-keeping cold storage is about 5℃, and the thickness of the insulation layer is 15cm.

·The temperature of the freezer is about -20℃, and the thickness of the insulation layer is 25cm.

If you are interested in our spray insulation equipment, please contact us immediately

Playlist

Good Review Of UREXCEED PU Spray Foam Machine

Mesin busa PU bertekanan rendah ini merupakan aset mutlak bagi proses produksi kami. Kami melihat kualitas dan efisiensi busa yang lebih baik.

Robert Smith Direktur TeknisMesin elastomer sangat efisien, dan kami telah melihat pengurangan waktu produksi yang signifikan. Ini adalah alat yang andal dan presisi.

Andre Dupont, seorang penulis Insinyur SeniorMesin TPU ini luar biasa! Mudah digunakan dan menghasilkan kualitas yang luar biasa. Kami telah melihat peningkatan yang sangat besar dalam produksi kami.

David Li Pengawas ManufakturKami telah melihat hasil yang luar biasa dengan mesin busa semprot ini. Mesin ini menghasilkan lapisan yang merata dan mudah dikontrol.

Mesin pelapis bekerja dengan lancar, mengaplikasikan lem dalam jumlah yang tepat setiap saat. Ini merupakan tambahan yang bagus untuk lini produksi kami.

Eliot Davis Direktur OperasionalApplication Of UREXCEED PU Spray Foam Machine

PU Spray Foam Machine For Insulation

PU Spray Foam Machine For waterproofing

PU Spray Foam Machine For Slab Lifting

Related Products About UREXCEED PU Spray Foam Machine

Polyurethane Foam Planer

Air Compressor

Mesin busa PU bertekanan tinggi telah meningkatkan efisiensi produksi kami. Mudah digunakan dan sangat andal.

John Williams Manajer Produksi