Advanced PU Foam Machines for Cold Chain

Itu rantai dingin industry involves a lot of product applications, including refrigerated trucks, cold storage panels, cake cabinets, kitchen refrigerators, beverage cabinets, wine cabinets, cigar cabinets, insulation boxes, turnover boxes, etc. The production of these cold chain products is inseparable from polyurethane foaming machines.

TERLEBIH DAHULU mesin pembuat busa poliuretan have diversified configurations and high efficiency, support multi-point injection, PLC control systems, and meet the needs of medium and large cold chain products manufacturers.

The Types of UREXCEED PU Foam Machines

There are two main types of polyurethane foaming machines for producing cold chain products, high pressure PU machines Dan low pressure PU foam machines. High pressure polyurethane machines can be divided into ordinary high pressure polyurethane foam machines Dan cyclopentane system high pressure pu foaming machines. You can choose different models based on your budget, site size and output.

High Pressure PU Machine

TERLEBIH DAHULU high pressure PU foaming machine adopts high-pressure airless mixing technology. The two liquid materials A(polyol) Dan B(isocyanate) are transported to the mixing head through a high-pressure metering pump. Under the impact of high pressure, they are instantly mixed and evenly sprayed out for foaming reaction.

Metering pump: Beijing granis/A2VK-28

Hydraulic pump 10L: HUDE

Mixing head: South Korea SPU 1218-2KV

Material tank: Homemade

Main electrical control system: Omron/schneider/CHINT

Water chilling unit: Zhongcheng

All configurations can be customized according to your requirements.

Self-cleaning L-type High Pressure Mixing Head

Three times repeated mixing, anti-jamming, anti-mixing, mechanical life casting more than 3 million times.

Fungsi Pembersihan Otomatis

High pressure reflux + self-cleaning design, no need for manual disassembly and cleaning

The Specification of High Pressure PU Foaming Mahcine

Nama | Parameters |

Raw material mixing pressure | 8~16MPa |

Theoretical injection volume | 270~1300g/sec |

Injection time setting range | 0. 5s~999.9s |

Raw material ratio adjustment range | 100:100~100:120 |

Injection metering accuracy | ≤±1% |

Material system working temperature | can be set |

Hydraulic system working temperature | ≤60℃ |

Hydraulic oil working pressure | 10~18 MPa |

Pneumatic working pressure | 0.2~0.8 MPa |

Robot effective working radius | 1800-2500mm |

Robot maximum load | 165kg |

Equipment total electrical power | ≥33.5KW |

Cyclopentane High Pressure Polyurethane Molding Machine

Cyclopentane high pressure polyurethane injection molding machine is a kind of high pressure polyurethane foam equipment specially used for using cyclopentane as foaming agent. It adds explosion-proof system and safety interlock control system on the basis of ordinary high pressure pu foaming machine, and is used to replace Freon foaming agent, which meets environmental protection requirements (such as the Montreal Protocol).

★The injection mixing head can move freely in six directions: front, back, left, right, up and down;

★The mixing head adopts dual proximity switch control to achieve precise injection;

★The inverter soft start and high and low frequency automatic switching are low-carbon, energy-saving and environmentally friendly, and energy consumption is greatly reduced.

The Specification of High Pressure PU Foaming Mahcine

No. | Barang | Technical Parameters |

1 | Applicable Foam Type | Busa Kaku |

2 | Applicable Material Viscosity (25°C) | Polyol/Cyclopentane: up to ~2500 mPa·s |

3 | Tekanan Injeksi | 6–20 MPa (adjustable) |

4 | Repeat Injection Accuracy | ±1% |

5 | Injection Flow Rate (Mixing Ratio 1:1) | 270–1300 g/s |

6 | Mixing Ratio Range | 1:1 to 1:1.5 (adjustable) |

7 | Injection Time | 0.5–99.99 s (accurate to 0.01 s) |

8 | Material Temperature Control Accuracy | ±2°C |

9 | Hydraulic System | System Pressure: 10–20 MPa |

10 | Material Tank Volume | 500 L |

11 | Sistem Kontrol Suhu | Heating: 2 × 6 kW |

12 | Explosion-Proof Standard | GB36.1-2000 “General Requirements for Explosion-Proof Equipment in Explosive Atmospheres”; Electrical Protection Level: IP54 or above |

13 | Power Supply | Three-phase four-wire, 380V / 50Hz |

Low Pressure Polyurethane Machinery

Polyurethane Low Pressure Foaming Machine is also a device used for polyurethane foam molding. Compared with high pressure PU machines, it adopts mechanical stirring and mixing. Itu equipment structure is relatively simple and the cost is low. It is mainly used for small and medium-scale production or application scenarios that do not require extreme foam fineness.

The low pressure polyurethane foam machine uses a low pressure gear pump to transport the two components A/B (usually polyol and isocyanate) to the mixing head in a set ratio. The mixing impeller in the mixing head mixes them and then sprays them out. The materials foam and solidify on the surface of the mold or workpiece.

Tangki Material

Double interlining heating material tank with insulation outer layer, heart rapidly, low energy consumption.

Pompa Pengukur

High precision JR series gear metering pump (pressure-tolerant 4MPa、speed 26~130r.p.m ), make sure the metering and ration accurate and stable.

No

| Barang | Parameter teknis |

1 | Aplikasi busa | Rigid foam |

2 | Raw material viscosity(22℃) | ~3000CPS ISO ~1000MPas |

3 | Keluaran injeksi | 225-900g/s |

4 | Mencampur kisaran ransum | 100:50~150 |

5 | Mixing head | 2800-5000rpm, pencampuran dinamis paksa |

6 | Volume tangki | 120L |

7 | Pompa pengukur | A pump: GPA3-63 Type B Pump: GPA3-63 Type |

8 | Sistem kontrol suhu | Heat:2×3.2Kw |

9 | Daya masukan | Three-phase five-wire 380V 50HZ

|

10 | Daya terukur | About 12KW |

If you want to more details of our pu foam machines

Jika pengantar di atas tidak dapat menjawab pertanyaan Anda, silakan hubungi kami secara langsung +8613656166310 Atau, tinggalkan informasi kontak dan kebutuhan Anda. Kami akan berusaha sebaik mungkin menghubungi Anda sesegera mungkin untuk menjawab pertanyaan Anda.

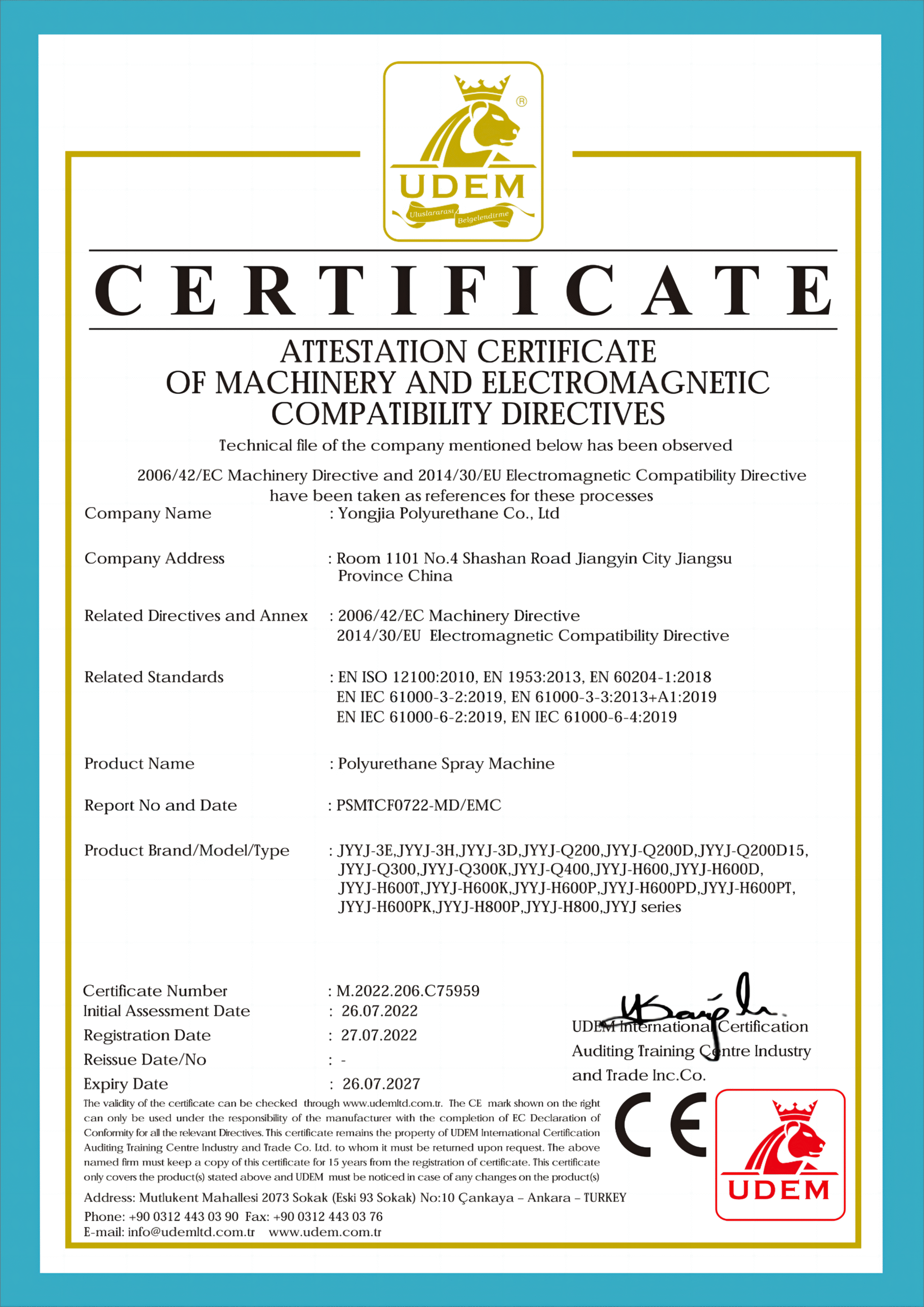

Sertifikasi dari

UREXCEED PU Foam Machines

Mengapa Memilih

UREXCEED PU Foam Machines

Kustomisasi Mesin Penuh

Untuk mesin pembusa poliuretan, pelanggan dapat dengan bebas memilih konfigurasi mesin sesuai anggaran mereka. Dari Siemens PLC hingga tangki material buatan sendiri, TERLEBIH DAHULU dapat menyesuaikan mesin sesuai dengan kebutuhan pelanggan.

Insinyur Berpengalaman

Kami memiliki insinyur mekanik yang berpengalaman. Selain menyesuaikan mesin sesuai kebutuhan pelanggan, TERLEBIH DAHULU juga dapat menyediakan instalasi di tempat dan layanan pelatihan untuk meningkatkan efisiensi pembelajaran pelanggan dan menghemat waktu pembelajaran pelanggan.

Penyedia Solusi Satu Atap

TERLEBIH DAHULU dapat menyediakan satu set lengkap jalur produksi rantai dingin, dari cetakan untuk mesin pembuat busa jalur perakitan lengkap, untuk memenuhi semua kebutuhan pelanggan untuk produksi rantai dingin.

Layanan Purnajual 24 Jam

TERLEBIH DAHULU Mesin PU memiliki A Garansi 1 tahun dan tindak lanjut melalui telepon dan video selama 3 tahun. TERLEBIH DAHULU dapat menyediakan layanan diagnosis jarak jauh untuk masalah apa pun.

Pelanggan dari

UREXCEED PU Foam Machines

UREXCEED telah menghadirkan mesin pembusa poliuretan berkualitas tinggi kepada pelanggan di lebih dari 100 negara dan wilayah di seluruh dunia.

FAQ tentang UREXCEED

PU Foam Machines

Pertanyaan dan jawaban yang paling sering diajukan

Ya, UREXCEED adalah produsen peralatan poliuretan dengan pengalaman lebih dari sepuluh tahun. Kami memiliki tim desain, teknisi, dan tim penjualan sendiri.

Pabrik kami berada di Jiangyin, Wuxi, sekitar 2 jam perjalanan dari Shanghai. Anda dapat naik kereta cepat langsung dari Shanghai ke Jiangyin, yang hanya memakan waktu 1 jam. Kami dapat menjemput Anda di stasiun kereta cepat.

Keduanya bekerja berdasarkan prinsip yang berbeda. Yang satu mengandalkan tekanan tinggi untuk mencampur bahan baku, dan yang lainnya mengandalkan pengadukan mekanis untuk mencampur bahan baku. Mesin bertekanan tinggi mencampur lebih sempurna, memiliki jangkauan aliran yang lebih luas, dan memiliki fungsi pembersihan otomatis. Mesin bertekanan rendah berukuran lebih kecil dan harganya lebih murah, serta dapat digunakan untuk memproduksi beberapa produk busa yang sangat kecil.

Berat produk yang perlu Anda produksi, hasil produksi, anggaran Anda, dan ukuran lokasi, dll.

45-60 hari.

Terbaru Berita

Of UREXCEED PU Foam Machines

Industri rantai dingin berperan penting dalam memastikan bahwa produk makanan, farmasi, dan biofarmasi tetap berada pada suhu rendah yang dibutuhkan selama transportasi dan penyimpanan. Karena permintaan konsumen akan keamanan pangan, kualitas produk, dan keberlanjutan lingkungan terus meningkat, industri rantai dingin mengalami pertumbuhan yang stabil, khususnya di…

Dalam industri rantai dingin, pangsa pasar bahan insulasi termal dipengaruhi oleh banyak faktor, termasuk persyaratan kinerja, pengendalian biaya, kebijakan perlindungan lingkungan, standar industri, dll. Jadi, kami akan memperkenalkan secara rinci pangsa pasar PU, EPS, VIP, Mineral Wool, PVC Foam, dan XPS dalam rantai dingin…

Dengan kemajuan globalisasi yang berkelanjutan dan meningkatnya permintaan akan makanan dan farmasi berkualitas tinggi dari konsumen, industri rantai dingin memainkan peran yang semakin penting dalam logistik global. Untuk memastikan kontrol suhu yang tepat selama transportasi dan penyimpanan, industri rantai dingin bergantung pada bahan insulasi berkinerja tinggi. Di antara berbagai…