Lini Produksi Panel Sandwich PU

- UREXCEED fully automated sandwich panel lines are engineered for 24/7 operation, ensuring consistent output of PU/PIR insulation panels for roofing, walls, and cold storage.

- Modular configurations are tailored to your desired panel types (EPS, rock wool, glass wool cores) and production capacity (5,000㎡ to 50,000㎡+ per day).

- Over 85% of raw materials are recycled during production, minimizing waste and supporting sustainable manufacturing.

Lini Produksi Panel Sandwich PU

Polyurethane composite plate production line is the best thermal insulation, heat insulation, sound insulation, flame retardant, waterproof, light, new wall building materials and environmental protection function, can be widely used in high-rise buildings and senior office wall maintenance and decoration, industrial plant, cold storage, purification room and insulated container.

With the development of new building system, steel structure change rapidly, especially the city high-rise buildings and office buildings and all kinds of modern industrial plants, steel structure of public facilities, the transportation is convenient, simple construction, demand for environmentally friendly polyurethane composite plate appearance and has insulation and decorative effect of the increased. Therefore, many foreign building, building materials machinery and special equipment manufacturing enterprises have set foot in this field, the technical content of polyurethane composite plate production line and continuously improve the production process, constantly updated, and greatly promoted the development of international steel construction industry and new wall materials industry.

Main Parameters Of PU Sandwich Panel Production Line

Speed of production line : 3-10 m/min (adjustable)

The total length of production line : about 160 meters

Working table height : 1200mm

Working pressure of foam pouring : 150-200 bar

The length of double-belt conveyor : 24 m

Control way: PLC controlling

Total Power: about 250kw (heating power is not included)

Power Supply : 380V/3 phases/50Hz

Control Voltage: 24V/110V/220V ; Pneumatic:0.7Mpa (factory brings along with their own)

Hubungi kami untuk penawaran lengkap

Mesin UREXCEED 30% lebih murah dibandingkan mesin Eropa

Each Part In The Sandwich Panel Production Line

This advanced polyurethane sandwich panel production line integrates several core systems to ensure high efficiency, precision, and automation. Each section plays a vital role in guaranteeing seamless operation, consistent product quality, and minimized labor input.

Uncoiler System

Function introduction:

- Hydraulic Expansion:Cantilever-type expansion with hydraulic centering for easy coil loading.

- Coiling Block Adaptability:Supports 508mm & 610mm coil ID via 4 arc plates; auto hydraulic expansion.

- Assistant Supporter:Prevents shaft deformation for 5T coils; V-type clamp enables fast coil changes (<45s).

- Drive System:Motor + reducer control bi-directional uncoiling; synced with main line via ultrasonic sensing.

- Center Adjustment:Hydraulic system adjusts ±75mm from center; clear scale markers included.

- Material Pressing Unit:Top-pressing unit set at 30–40° to prevent frame collision during operation.

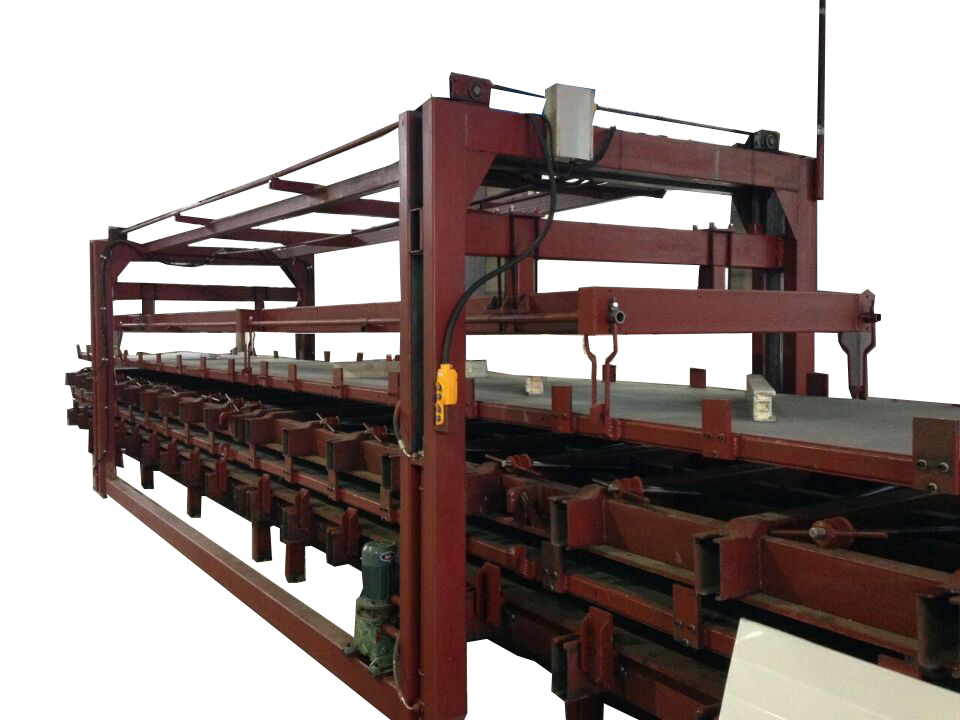

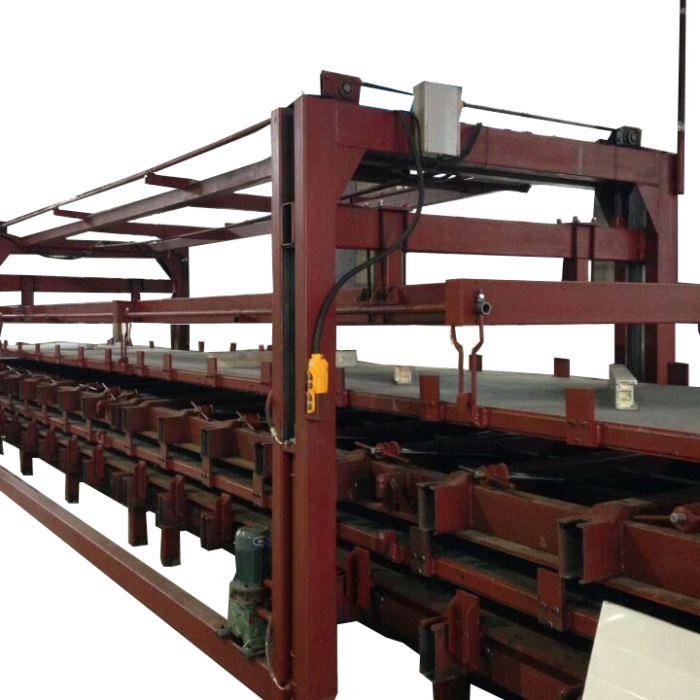

Up Panel Lifting Device

The function up panel lifting device is used for leading the steel panel into the up roll forming machine from the ground.

Technical parameter:

- Gantry type frame, adopts welded steel structure

- Lifting motor power: 1.5KW

- Feeding motor power: 0.75KW

- Up and down lifting & feeding roller: a pair of roller, surface of chain drive roller coated with PU

- Feeding cylinder: SC63*25(2 pcs)

- Feeding and lifting unit: feeding unit has the function of lifting the steel panel

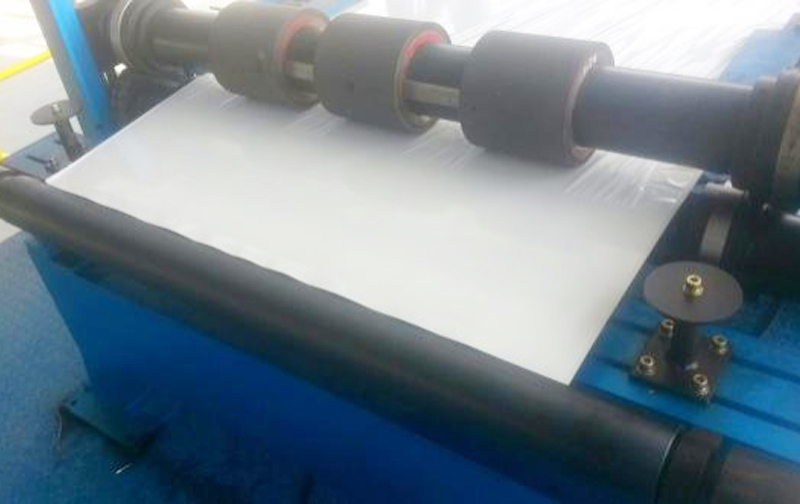

Filming Device

Fungsi Introduction:

The filming unit uses an air-expanding roller (∮75mm ID) to fix the film coil. Powered drum-type press and support rollers ensure stable film application. Left-right adjustment aligns film with steel panels for smooth, bubble-free lamination. The rotating shaft allows easy coil handling, and ample space enables operators to attach the film head efficiently.

Technical Parameter:

- Inner diameter of coiling block for fixing film coil: ∮75mm

- Diameter of air expanding roller: ∮75mm

- Air expanding pressure: above 5kgs

- Film frame weight capacity: 100kgs

- There are both uncoiling stand for up and down forming machine

- Uncoiling with brake function

- Poll knife motor power:0.75kw

- Poll knife speed : about 50 m/min

- Driving roller motor power : 1.5kw

- Driving roller speed: about 18m/min

Cutting Device, Side Slitting & Rewinding Device

Transverse machine framing pre-cutter is used to cut off the steel panel when finish the single batch of order, so that can avoid the waste.

Slitting unit can meet the requirement to produce different products with the standard steel coil.

Technical Parameter:

- Supporting roller: φ60mm

- Material of blade: Gr12mov

- Hardness of blade: HRC60°-62°

- Motor power: 4kw

- Plane cutter base linear guide rail: 2 sets

- Slitting width: min. 5mm, max. 150mm

- Slitting thickness: 0.3-0.8

- Slitter base guide rail: 4 sets

Heating System

Steel Plate Preheating Furnace

Preheatng furnace body,heating unit,air duct and related accessories,temperature control system and so on.

Steel Plate Preheating Furnace

Preheatng furnace body,heating unit,air duct and related accessories,temperature control system and so on.

The preheating furnace uses hot air circulated via a heat exchanger and fan system to heat both upper and lower steel sheets. This ensures better bonding and stable foaming. Temperature is steplessly adjustable with built-in heat recycling. A thermal detector monitors and displays temperature data. Heating sources can be gas, oil, or electricity, provided by the user.

Main Structure

The furnace body, heating equipment, and air ducts are made of galvanized and colored steel, with thermal insulation material inside. Both upper and lower guide rollers use galvanized rollers for durability and smooth operation.

Technical Parameters

Steel width : Max 1200mm

Heating capacity : 43000kcal/h

Circulation fan air volume : about 4200 cubic meter/h

Plate velocity : Max 8 m/min

Preheating furnace length : 5 m

Blast blower motor power : 5.5 kw

Temperature control uniformity : less than ±3

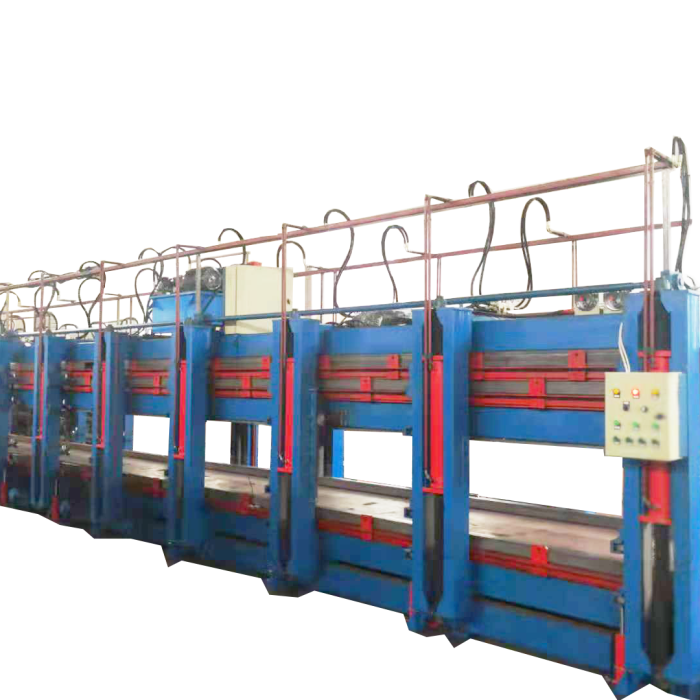

Double-Belt Temperature Control System

The hot air circulation system evenly heats the panels, enhancing foam stability and adhesion.

Double-Belt Temperature Control System

The hot air circulation system evenly heats the panels, enhancing foam stability and adhesion.

This system uses hot air circulation to heat the upper and lower crawler panels uniformly as they move at a constant speed. The heating improves PU foam curing stability and adhesion, reducing bubbles and foam spots. Heat is generated via an electric heating device and distributed through upper and lower air ducts, with the exchanger mounted atop the double crawler belt.

Technical parameters:

Double-belt plate working temperature: 45 ℃(PU)

The warming time of chain plate (Room temperature) to the working temperature Heating capacity: 2*43000kcal/h

Circulation fan air volume: about 2*4200 cubic meter/h

Blast blower motor power: 5.5 kw *2

Temperature control uniformity: less than ±3 ℃

If you want to know more about sandwich panel production line , feel free to contact us

Daftar Putar

Good Review Of UREXCEED PU Sandwich Panel Production Line

UREXCEED polyurethane sandwich panel production line has received widespread praise from global customers for its automation, stability, and cost-efficiency. Here’s what some of our partners have to say:

The whole system is stable and well-designed. Our output has increased without extra manpower.

Jonas Becker AustraliaReliable quality and low maintenance. A smart investment for any insulation panel producer.

Lucas Fernandes Uni Emirat ArabInstallation was smooth, and training was professional. Great ROI within the first few months.

Prakash Mehta Jerman

The production line runs smoothly with minimal downtime. Very efficient and easy to operate. Great support from the team!

Ahmet Demir Chili