Lini Produksi Kulkas & Freezer PU

TERLEBIH DAHULU Menyediakan solusi lini produksi lengkap untuk kabinet busa pada kulkas, freezer, lemari pajangan komersial, dan peralatan pendingin lainnya. Cocok untuk pabrik baru atau proyek perluasan, dan mendukung kustomisasi sesuai permintaan, pengiriman cepat, serta instalasi dan komisioning di lokasi global.

Jenis Lini Produksi Kulkas dan Freezer UREXCEED PU

Lini produksi kulkas dan freezer dirancang dan dikembangkan oleh TERLEBIH DAHULU terutama termasuk tipe rel tanah, tipe bergerak, tipe linier, tipe putar, dll. sesuai dengan jalur produksi yang berbeda.

Jalur Produksi PU Rel Tanah untuk Produksi Kabinet Kulkas & Freezer

Lini produksi ini dikembangkan untuk lemari es, freezer, lemari pajangan, dan komponen struktural kotak lainnya. Lini ini terdiri dari sistem penggerak rantai, perlengkapan pembusa, oven, platform mesin pembusa, sistem pemanas dan pembuangan uap, manipulator pengisian, mekanisme pembuka kunci, troli pengangkut, rel pemandu pembuka dan penutup, perangkat penjepit tambahan, sistem pneumatik pendukung, sistem hidrolik, sistem kontrol elektronik, dll., untuk mencapai pencetakan busa poliuretan PU yang efisien, akurat, dan batch. Lini ini dapat dihubungkan dengan seluruh operasi aliran lini dan banyak digunakan dalam proses pengisian kotak produk rantai dingin seperti lemari es rumah tangga, lemari pajangan supermarket, dan peralatan katering.

Sirkulasi Otomatis Penuh

Sistem rel loop tertutup untuk produksi batch yang konsisten

Injeksi Akurat

Injeksi tekanan tinggi multi-titik menghindari penyusutan atau rongga

Spesifikasi Lini Produksi PU Rel Tanah

Barang | Spesifikasi |

Dimensi Keseluruhan (P×L×T) | Sekitar 29.500 × 7.950 × 3.350 mm |

Jumlah Stasiun | 26 |

Ukuran Template Perlengkapan | Ukuran 2.000 × 900 mm |

Tinggi Penutupan Cetakan | 200 mm (dapat disesuaikan berdasarkan permintaan) |

Waktu Siklus Produksi | 20 detik (tidak termasuk waktu operasi manual) |

Metode Pemanasan | Pemanasan uap atau pengontrol suhu cetakan minyak |

Bahan Berbusa | POL + Siklopentana + ISO, atau POL + 141b + ISO |

Metode Injeksi | Penuangan vertikal manual dengan cetakan terbuka |

Kapasitas Uap | 200 m³/jam |

Suhu Oven Pengeringan | 55 ± 5 derajat celcius |

Suhu Uap | 120–150°C |

Persyaratan Udara Terkompresi | Tekanan kerja ≥ 0,5 MPa; Aliran udara sekitar 0,1 m³/menit |

Konsumsi Daya | – Dengan pemanas uap: sekitar 25 kW (380V, 50Hz) |

Lini Produksi PU Garis Lurus untuk Lemari Kulkas & Freezer

Lini produksi busa mengadopsi tata letak linier, terdiri dari oven pemanas awal, lini rol daya, mesin pemutar 90° untuk kotak masuk (termasuk identifikasi kotak), sistem transportasi dua arah (yang mungkin mencakup perangkat pengisian nitrogen otomatis), perlengkapan produksi busa, sistem pengisian otomatis, mesin pengangkat dan penerjemah outlet, sistem pemanas air cetakan eksternal, dan sistem pneumatik pendukung dan sistem kontrol elektronik. Perlengkapan memiliki fungsi pemblokiran gelembung otomatis, dan penggantian cetakan mengadopsi silinder atau mekanisme batang penghubung yang digerakkan secara manual, yang memiliki fungsi penguncian otomatis ganda dari kontrol manual dan kontrol listrik. Cocok untuk kapasitas produksi skala kecil dan menengah atau skenario manufaktur lini campuran multi-spesifikasi. Lini produksi memiliki karakteristik penampilan yang indah, struktur kompak, polusi lingkungan yang lebih sedikit, intensitas tenaga kerja yang rendah, tapak kecil, fungsi yang kuat, efisiensi produksi yang tinggi, dan produksi yang fleksibel dari berbagai varietas.

Kemampuan multi-model

Mendukung cetakan yang dapat dialihkan untuk berbagai jenis kabinet

Otomatisasi tinggi

Lebih sedikit tenaga kerja, efisiensi lebih baik

Spesifikasi Lini Produksi PU Garis Lurus

Barang | Spesifikasi |

Kisaran Ukuran Kabinet | Panjang: 800–2000 mm; Lebar: 450–800 mm; Kedalaman: 450–900 mm |

Waktu Pengeringan | Dapat disesuaikan dalam 999 detik |

Jumlah Stasiun | 6–8 |

Metode Injeksi | Penuangan horizontal kepala tunggal dari satu ujung |

Bahan Berbusa | POL + Siklopentana + ISO, atau POL + 141b + ISO |

Waktu Siklus Produksi | 30 detik/unit (tergantung pada jumlah perlengkapan dan waktu pengeringan) |

Variasi Produk | Mendukung produksi simultan 6–8 ukuran produk yang berbeda |

Penggerak Pengangkat Perlengkapan | Digerakkan oleh motor |

Voltase | Tegangan 380V, 50Hz |

Total Daya Lini Produksi | Maks ≤ 190 kW, Daya kabinet eksternal: 24V |

Persyaratan Udara Terkompresi | Tekanan kerja ≥ 0,5 MPa; Aliran udara sekitar 0,1 m³/menit |

Lini Produksi PU Rotary untuk Pintu Kulkas dan Freezer

Lini pembusa adalah peralatan pembusa pintu putar (tipe hub) dengan tujuh (delapan) stasiun, yang terutama digunakan untuk pembusaan pintu lemari es (kabinet). Lini ini terdiri dari rangka utama, rangka putar, rangka cetakan pembusa, penggerak hidrolik, pemosisian, sistem buka-tutup cetakan, sistem injeksi dan transfer material, sistem identifikasi varietas, sistem hidrolik pendukung, dan sistem kontrol elektrik. Template penjepit dipanaskan dengan air. Penjepitan cetakan aman dan andal, serta penggantian cetakan mudah dan cepat, cocok untuk produksi fleksibel berbagai varietas. Lini produksi ini memiliki karakteristik ukuran kecil, struktur kompak, dan pengoperasian yang mudah.

Tata letak putar kompak

Desain hemat-ruang untuk lantai pabrik berukuran sedang

Waktu siklus cepat

Efisien untuk produksi volume sedang hingga tinggi

Spesifikasi Lini Produksi PU Rotary

Barang | Spesifikasi |

Dimensi Keseluruhan (P×L×T) | Sekitar 000 × 5500 × 4600 mm |

Jumlah Stasiun | 7 (8) |

Ukuran Template Perlengkapan (P×L) | Ukuran 2000 × 900 mm |

Tinggi Penutupan Cetakan | 200 mm |

Waktu Siklus Produksi | 46 detik (tidak termasuk waktu operasi manual) |

Bahan Berbusa | POL + Siklopentana + ISO, atau POL + 141b + ISO |

Metode Injeksi | Penuangan otomatis dengan cetakan terbuka |

Metode Pemanasan | Pemanasan air melalui pengontrol suhu cetakan |

Persyaratan Daya | Sekitar 65 kW (380V, 50Hz) |

Jika Anda ingin mengetahui lebih detail tentang lini produksi lemari es dan freezer

Jika pengantar di atas tidak dapat menjawab pertanyaan Anda, silakan hubungi kami secara langsung +8613656166310 Atau, tinggalkan informasi kontak dan kebutuhan Anda. Kami akan berusaha sebaik mungkin menghubungi Anda sesegera mungkin untuk menjawab pertanyaan Anda.

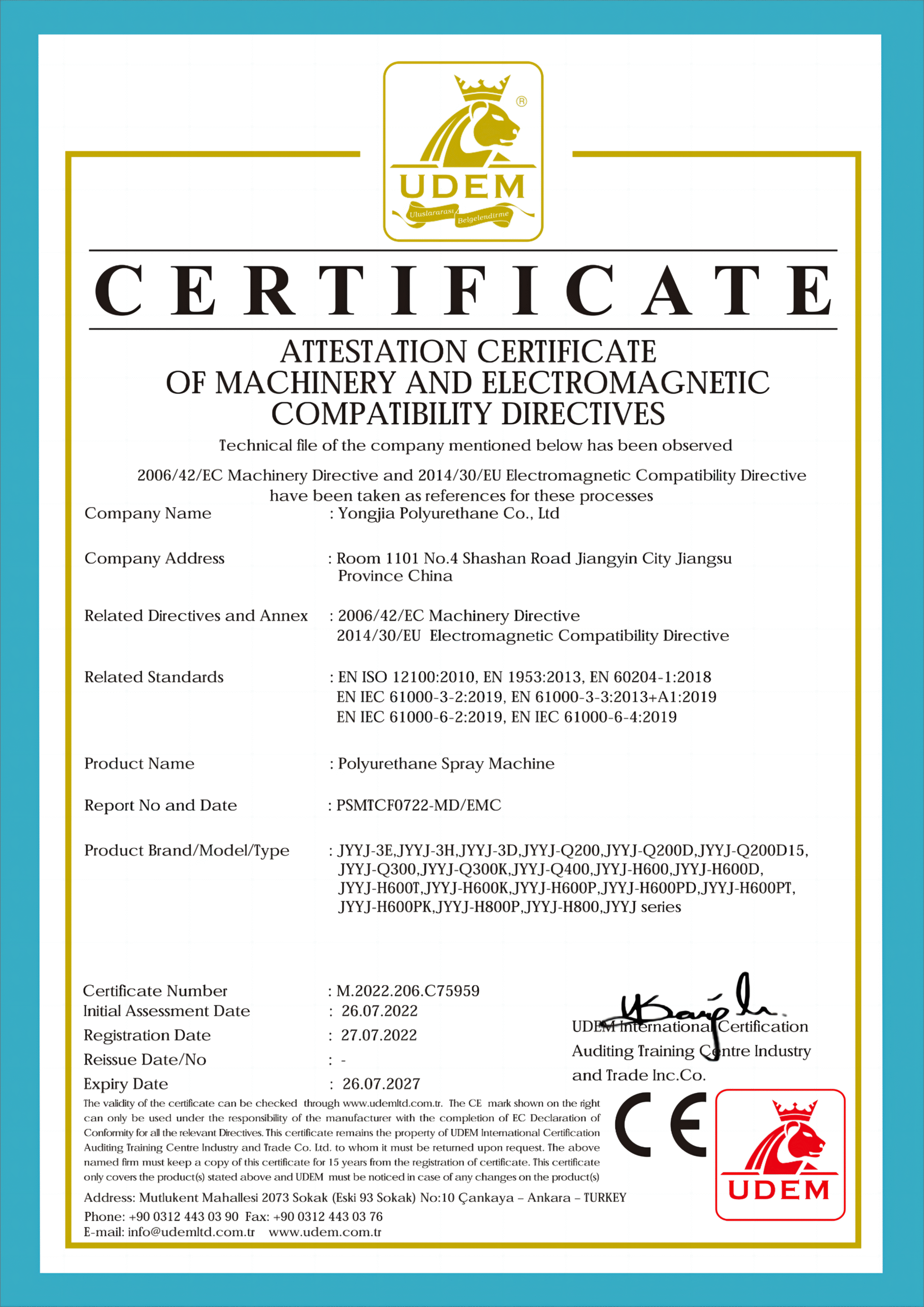

Sertifikasi dari

Lini Produksi PU UREXCEED

Mengapa Memilih

Lini Produksi Busa PU UREXCEED

Kustomisasi Mesin Penuh

Untuk mesin pembusa poliuretan, pelanggan dapat dengan bebas memilih konfigurasi mesin sesuai anggaran mereka. Dari Siemens PLC hingga tangki material buatan sendiri, TERLEBIH DAHULU dapat menyesuaikan mesin sesuai dengan kebutuhan pelanggan.

Insinyur Berpengalaman

Kami memiliki insinyur mekanik yang berpengalaman. Selain menyesuaikan mesin sesuai kebutuhan pelanggan, TERLEBIH DAHULU juga dapat menyediakan instalasi di tempat dan layanan pelatihan untuk meningkatkan efisiensi pembelajaran pelanggan dan menghemat waktu pembelajaran pelanggan.

Penyedia Solusi Satu Atap

TERLEBIH DAHULU dapat menyediakan satu set lengkap jalur produksi rantai dingin, dari cetakan untuk mesin pembuat busa jalur perakitan lengkap, untuk memenuhi semua kebutuhan pelanggan untuk produksi rantai dingin.

Layanan Purnajual 24 Jam

TERLEBIH DAHULU Mesin PU memiliki A Garansi 1 tahun dan tindak lanjut melalui telepon dan video selama 3 tahun. TERLEBIH DAHULU dapat menyediakan layanan diagnosis jarak jauh untuk masalah apa pun.

Pelanggan dari

Lini Produksi Busa PU UREXCEED

UREXCEED telah menghadirkan mesin pembusa poliuretan berkualitas tinggi kepada pelanggan di lebih dari 100 negara dan wilayah di seluruh dunia.

FAQ tentang UREXCEED

Lini Produksi Busa PU

Pertanyaan dan jawaban yang paling sering diajukan

Ya, UREXCEED adalah produsen peralatan poliuretan dengan pengalaman lebih dari sepuluh tahun. Kami memiliki tim desain, teknisi, dan tim penjualan sendiri.

Our factory is in Jiangyin, Wuxi, about 2 hours’ drive from Shanghai. You can take the high-speed rail directly from Shanghai to Jiangyin, which only takes 1 hour. We can pick you up at the high-speed rail station.

They work on different principles. One relies on high pressure to mix raw materials, and the other relies on mechanical stirring to mix raw materials. The high-pressure machine mixes more fully, has a wider flow range, and has a self-cleaning function. The low-pressure machine is smaller in size and cheaper in price, and can be used to produce some particularly small foam products.

The weight of the product you need to produce, the product output, your budget and the size of the site, etc.

Terbaru Berita

Of UREXCEED PU Foam Production Line

Industri rantai dingin berperan penting dalam memastikan bahwa produk makanan, farmasi, dan biofarmasi tetap berada pada suhu rendah yang dibutuhkan selama transportasi dan penyimpanan. Karena permintaan konsumen akan keamanan pangan, kualitas produk, dan keberlanjutan lingkungan terus meningkat, industri rantai dingin mengalami pertumbuhan yang stabil, khususnya di…

Dalam industri rantai dingin, pangsa pasar bahan insulasi termal dipengaruhi oleh banyak faktor, termasuk persyaratan kinerja, pengendalian biaya, kebijakan perlindungan lingkungan, standar industri, dll. Jadi, kami akan memperkenalkan secara rinci pangsa pasar PU, EPS, VIP, Mineral Wool, PVC Foam, dan XPS dalam rantai dingin…

Dengan kemajuan globalisasi yang berkelanjutan dan meningkatnya permintaan akan makanan dan farmasi berkualitas tinggi dari konsumen, industri rantai dingin memainkan peran yang semakin penting dalam logistik global. Untuk memastikan kontrol suhu yang tepat selama transportasi dan penyimpanan, industri rantai dingin bergantung pada bahan insulasi berkinerja tinggi. Di antara berbagai…