Want consistent, high-quality PU foam? High-pressure machines might be the answer, but how do they actually work?

High-pressure PU foam machines mix polyol and isocyanate at very high speeds, creating a fine, consistent foam. They use precise metering, temperature control, and self-cleaning mixing heads for optimal results.

Interested in learning more about how these machines achieve such impressive results? Keep reading to dive into the details.

Polyurethane High-Pressure Foaming Machine: Why Choose High-Pressure Technology?

High-pressure foaming machines offer several advantages over low-pressure systems. The main reason to choose high-pressure is the superior mixing quality. Because the polyol and isocyanate are forced together at very high speeds, the mixing is extremely thorough and homogenous. This leads to a finer and more consistent cell structure in the resulting foam. Also, high-pressure machines have self-cleaning mixing heads, which reduces downtime and maintenance. All those advantages make them a good choice for high-volume production and applications where consistent foam quality is critical.

What are the Core Components and Functions of a High-Pressure Foaming Machine?

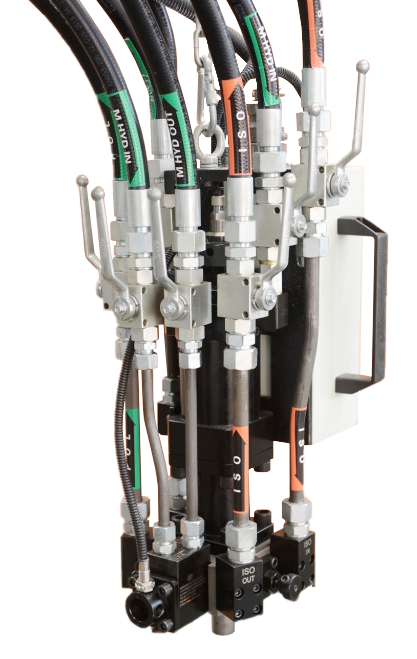

A high-pressure foaming machine is made up of several key components, each with a specific function. The tanks hold the polyol and isocyanate. Pumps precisely meter the two components. A mixing head mixes the polyol and isocyanate at high speed. Control systems monitor and adjust the machine’s parameters. The metering system is especially important. High-pressure machines use piston pumps or gear pumps combined with flow meters to deliver the exact ratio of components. The accuracy of metering directly affects the foam’s density and cell structure.

What is the Internal Working Principle of a High-Pressure Mixing Head?

The mixing head is where the magic happens in a high-pressure PU foam machine. Inside the mixing head, the polyol and isocyanate are injected into a small chamber at very high velocities. This creates a turbulent flow, resulting in rapid and complete mixing. After dispensing, a small piston or needle scrapes away any residual material, which keeps the head clean. This self-cleaning feature is a major advantage of high-pressure machines, because it reduces downtime and maintenance.

What are the Key Points for Controlling the High-Pressure Foaming Process?

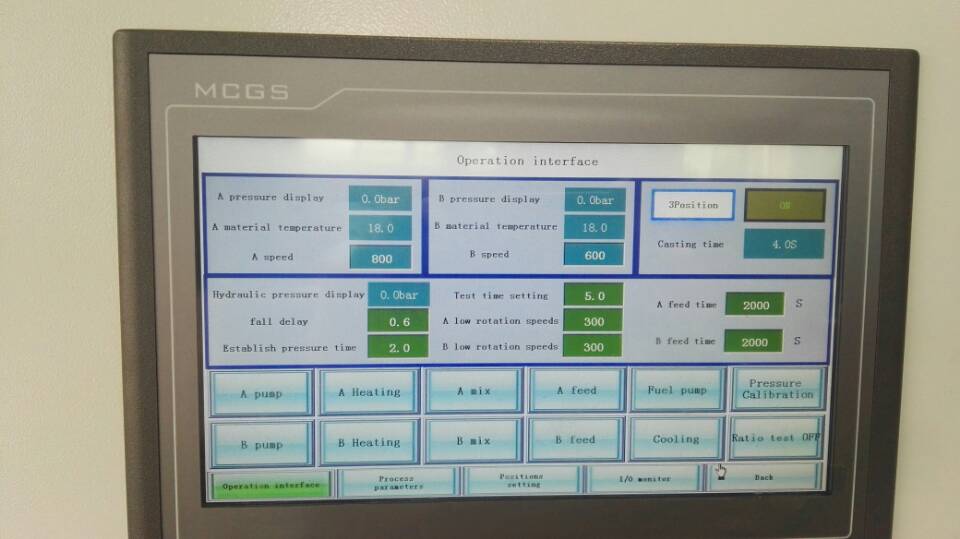

To get consistent results, you need to carefully control the high-pressure foaming process. Here are some key things to keep in mind:

- Precise Metering: Make sure the polyol and isocyanate are metered accurately and consistently.

- Kontrol Suhu: Keep the components at the correct temperature to ensure consistent viscosity and reactivity.

- Pressure Regulation: Control the pressure within the mixing head to achieve the desired cell structure.

- Mixing Ratio: Maintain the correct mixing ratio of polyol and isocyanate to achieve the desired foam properties.

Modern machines use closed-loop control systems that continuously monitor these parameters and automatically adjust the machine’s settings.

What are the Common Failures and Troubleshooting Methods of High-Pressure Foaming Machines?

Like any complex piece of machinery, high-pressure foaming machines can experience failures. Here are some common issues and how to troubleshoot them:

| Failure | Possible Cause | Troubleshooting Method |

|---|---|---|

| Inconsistent Foam | Metering issues, temperature variations | Check flow meters, temperature sensors, and control systems. |

| Mixing Head Clogging | Incomplete cleaning, reactive buildup | Inspect and clean mixing head, adjust cleaning cycle, use compatible raw materials. |

| Pump Failure | Wear and tear, contamination | Inspect pump components, replace worn parts, flush system to remove contaminants. |

| Pressure Fluctuations | Air in system, faulty pressure regulators | Bleed air from system, inspect and replace pressure regulators. |

| Material Degradation | Improper storage, excessive recirculation | Ensure proper storage conditions, optimize recirculation system to minimize material exposure to heat and oxygen. |

Regular maintenance and careful monitoring of the machine’s performance can help prevent these failures.

What are the Future Development Trends of High-Pressure Polyurethane Foaming Machines?

The future of high-pressure polyurethane foaming machines is focused on improving efficiency, sustainability, and control. Some trends include:

- More precise control systems: Advanced sensors and algorithms will allow for even more precise control over the foaming process.

- Use of sustainable materials: The industry is moving towards the use of bio-based polyols and blowing agents to reduce environmental impact.

- Improved energy efficiency: New machine designs will focus on reducing energy consumption.

- Integration with automation: High-pressure foaming machines will be integrated with robots and other automated systems for increased productivity.

One thing I’ve learned over the years is that the “best” high-pressure machine is the one that’s properly matched to the specific application and raw materials. Don’t overspend on features you don’t need. Focus on reliability, ease of maintenance, and the availability of technical support. Also, build a strong relationship with your raw material suppliers – their expertise can be invaluable in optimizing your process. I’ve been in this industry for 50 years, and I’ve seen a lot of changes. But one thing that hasn’t changed is the importance of understanding your materials and your process.

Kesimpulan

High-pressure PU foam machines offer precision and consistency. Understanding their workings helps achieve optimal foam quality.