메모리폼 베개 생산 라인

UREXCEED polyurethane memory pillow production line is designed for efficient and precise manufacturing of memory foam pillows, making it the ideal choice to meet modern market demands. This production line features advanced 고압 발포 기술정밀한 금형 설계와 자동화된 제어 시스템을 결합하여 각 베개가 뛰어난 형상 기억 성능과 탁월한 편안함을 제공하도록 보장합니다.

UREXCEED의 프로세스 흐름 Pillow Production Line

PU Foam Pillow Product Process

1단계

2단계

3단계

4단계

5단계

Gel Pillow Product Process

1단계

2단계

3단계

4단계

5단계

6단계

7단계

UREXCEED 소개 폼 필로우 생산 라인

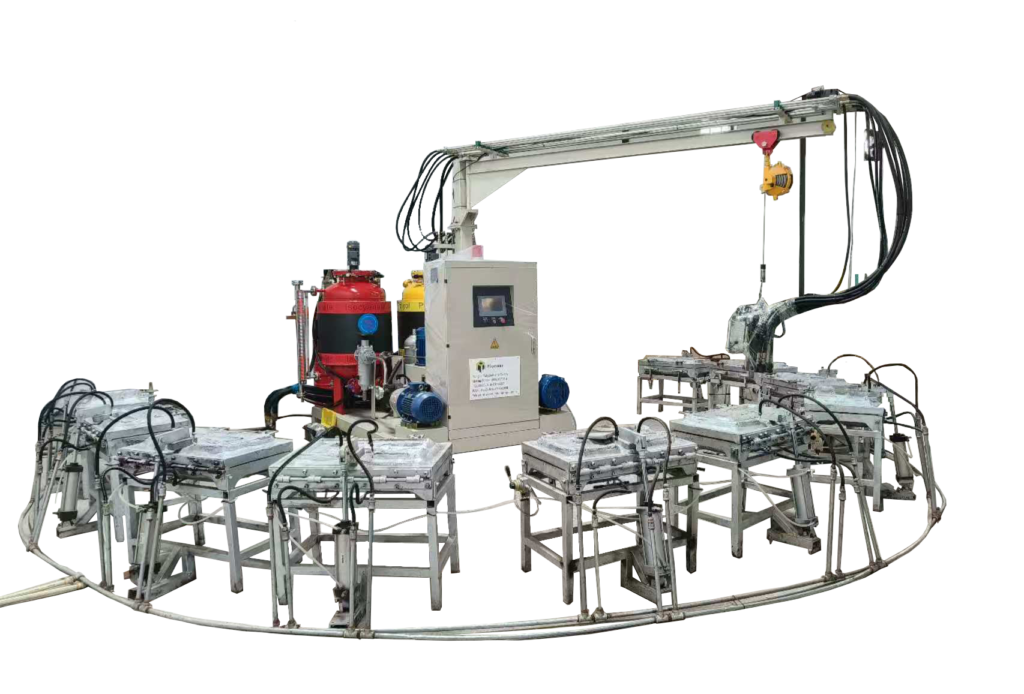

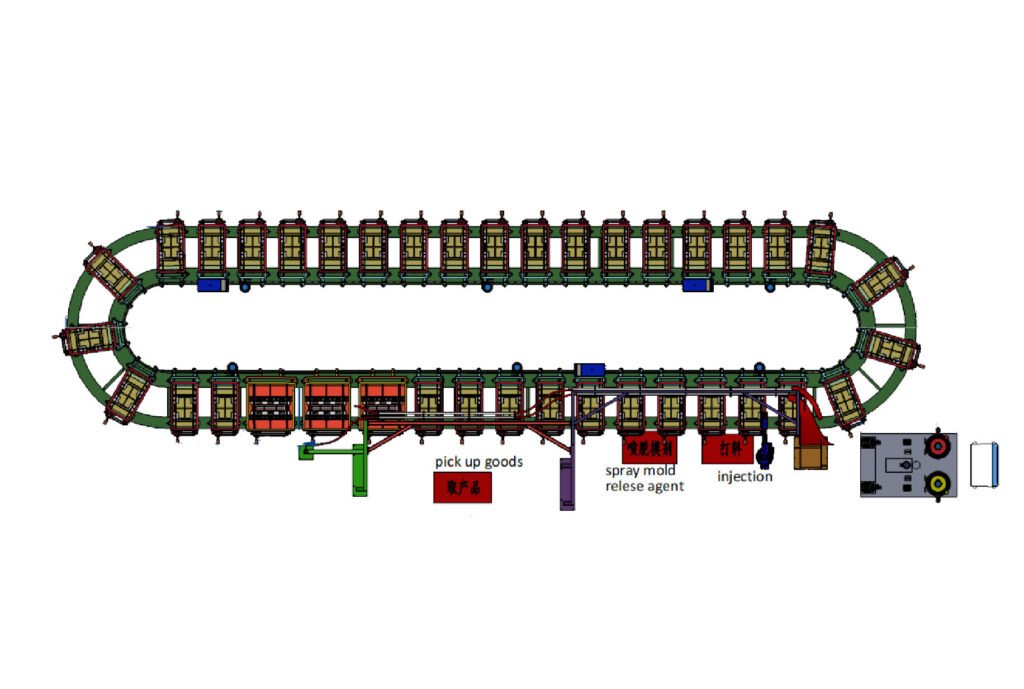

UREXCEED offer a variety of customizable production lines, including carousel lines, rotary lines, and banana lines, designed to meet the specific needs of different manufacturing processes. Each production line type is engineered for maximum efficiency, flexibility, and scalability, enabling businesses to optimize their production while maintaining high-quality standards.

생산 요구 사항의 복잡성이나 규모에 상관없이 UREXCEED는® 당신에게 맞는 라인을 제공하여 최대 생산성과 최소 가동 중단 시간을 보장합니다. 당사의 포괄적인 솔루션은 효율성을 개선하고, 운영 비용을 절감하고, 전반적인 제조 공정을 향상하도록 설계되었습니다.

바나나 생산 라인

장시간 냉각이 필요한 공정에 사용됩니다.

작동 방식: 금형이 곡선 경로를 따라 움직이므로 특정 생산 단계에서 더 많은 시간을 사용할 수 있습니다.

장점:

·더 크거나 밀도가 높은 베개 등 경화 시간이 길어야 하는 제품에 이상적입니다.

·중요 단계의 시간을 늘려 생산 병목 현상을 줄입니다.

·공장 레이아웃 및 생산 공정에 맞게 높은 사용자 정의가 가능합니다.

제한 사항:

·원형 및 디스크형 라인에 비해 더 큰 공간이 필요합니다.

·특수 또는 수요가 높은 생산 공정에 가장 적합합니다.

차이점 요약

| 생산라인 | 주요 특징 | 가장 적합한 | 공간 요구 사항 | 생산능력 |

|---|---|---|---|---|

| 회전식 생산 라인 | 중앙 회전 디스크 | 소규모 생산 | 낮은 | 낮은 |

| 회전 생산 라인 | 연속적인 원형 트랙 | 대규모 유니폼 생산 | 중간 | 높은 |

| 그라운드 레일 회전 라인 | 바닥에 내장된 레일 시스템 | 무거운 금형, 대용량 생산 | 중간-높음 | 높은 |

| 바나나 생산 라인 | 확장된 곡선 트랙 | 장시간 경화/냉각 공정 | 높은 | 중간-높음 |

추천:

- 디스크 또는 원형 라인: 적당한 공간과 예산으로 표준 메모리폼 베개 생산에 적합합니다.

- 지상 레일 순환선: 대용량 또는 무거운 금형에 중점을 둔 공장에 이상적입니다.

- 바나나라인: 장시간 경화 또는 냉각이 필요한 복잡한 제품에 가장 적합합니다.

원스톱 솔루션 PU 폼 베개 생산 라인

UREXCEED foam pillow production line one-stop service is designed to provide customers with a comprehensive solution, from raw material sourcing to equipment installation and commissioning, as well as mold customization and production line setup. UREXCEED supply high-quality polyurethane raw materials, ensuring the comfort and durability of the pillows, and provide advanced foam pillow production equipment, including 고압/저압 발포기, automated assembly lines, and more, helping you improve production efficiency and reduce labor costs. Additionally, UREXCEED custom mold services allow for the production of molds in various sizes and styles to meet customer needs, ensuring product accuracy and consistency. Through this complete one-stop service, we help clients simplify the procurement process, reduce production risks, and enhance market competitiveness.

Raw material system

- Isocyanate (MDI): a key reaction component that affects the support and rebound properties of the foam.

- Polyether Polyol: Determines the softness and viscoelasticity of foam, and is the main material for regulating softness and hardness.

- Water: Reacts with isocyanates to produce CO ¾ gas, forming a pore structure and controlling the foaming rate.

- Catalyst: Adjust the foaming reaction rate, control the initiation time and molding efficiency.

- Crosslinking agent: enhances the stability of the foam structure, improves pressure resistance and durability.

- Emulsifiers/Surfactants: Optimize pore uniformity to prevent defects such as collapse and poor foaming.

- Auxiliaries (optional): antioxidants, anti-yellowing agents, flame retardants, fragrances, color pastes, antibacterial additives, etc., can be customized according to the target market

| Pillow type | Shore hardness (A) | Applicable population | Feature Description |

| Soft pillow | 10–15 | Women/children | Soft fit, low rebound |

| Medium soft (universal type) | 15–22 | Mass consumer market | Support + Comfort Balance |

| Rigid brace type | 22–30 | Cervical Support/Men’s Market | Obvious support, high rebound |

- The softness and hardness range of the pillow can be flexibly adjusted by the type and ratio of polyether (such as Shore hardness A 10-30).

- Can provide environmentally friendly, low VOC formulas, support REACH/CertificPUR certification requirements

- Customized fragrances, densities, and skin feel for different end point markets (cross-border e-commerce, high-end home furnishings, offline channels)

- A/B component storage tank (200L × 2)

- Precision heating constant temperature system (temperature control range 20-25 ℃)

- Mixing device (to prevent sedimentation)

- Pipeline pressurized circulating feeding system (connecting foaming equipment)

폼 머신

| Project | High Pressure Foaming Machine | Low Pressure Foaming Machine |

| Working principle | Components A and B are mixed by high-pressure impact without mechanical stirring | Components A and B are mixed by mechanical agitation in the mixing head |

| Working pressure | 120–200 bar | Atmospheric or low pressure (< 10 bar) |

| Injection method | Mechanical arm automatic feeding/fixed-point feeding system | Manual injection/Simple guide rail injection |

| Mixing uniformity | Very high, fine and uniform pores | Generally, there may be slight color differences or hardness fluctuations |

| Cleaning method | High-pressure self-cleaning, usually without solvent | Manual cleaning, using organic solvents |

| Product consistency | Excellent, suitable for high-standard products | Generally, it is greatly affected by manual operation |

| Automated adaptability | Highly compatible with automated production lines | Suitable for manual operation, limited automation capability |

| Equipment costs | Higher (about 1.5-2 times that of a low-voltage machine) | Low, suitable for small and medium-sized initial investments |

| Raw material adaptation requirements | Higher temperature and viscosity control requirements for raw materials | Strong adaptability to raw material conditions |

| Applicable scenarios | High-end brands/export orders/high-quality foam | Start-up factories/small batch production/markets with low labor costs |

| Advantages summary | Good mixing effect, no installation, easy to clean, high efficiency | Low cost, simple structure, easy maintenance |

| Summary of shortcomings | High investment costs and strict requirements for raw material conditions | Cleaning is cumbersome, and product consistency is slightly poor |

| Indicator | High pressure pu foam machine | Low pressure pu foam machine |

| Mixed mode | High speed impact | Mechanical stirring |

| Mixing uniformity | ★★★★★ | ★★★☆☆ |

| Cost inputs | 높은 | Medium/Low |

| Adapt to automation | Support (recommended) | Basically not supported |

| Cleaning method | Self-cleaning | Solvent cleaning |

| Recommended yield | More than 1000 pieces/day | Less than 500 pieces/day |

- If your goal is to establish an automated and standardized plant, it is recommended to prioritize high-pressure systems.

- For customers with limited budgets or in the verification stage, they can start with low-voltage systems and upgrade later.

- We can recommend the most suitable foaming system solution based on your formula viscosity, daily production target, and operating team configuration.

Mold system

Mold material:

- Good thermal conductivity, fast heating, stable temperature control → shorten the foaming reaction and cool down, and improve production capacity

- Lightweight design for easy manual handling or automatic demolding and grabbing

- Surface treatment is smooth, supporting various surface processes such as mirror polishing/texture etching

- Strong corrosion resistance and resistance to polyurethane raw material erosion

- Long service life, up to 20-300,000 cycles on average

- Polished surface: suitable for soft touch pillows, simple appearance

- Corrosion imitation fabric: improve anti-slip performance, simulate fabric visual

- Mirror plating: used for high-end customization to enhance texture

Mould base:

The mold frame is used to support and fix the mold, which directly affects the opening and closing efficiency and operational safety of the mold. According to the degree of automation and production capacity requirements, the mold frame is mainly divided into the following categories.

- The opening and closing of the mold is completed by manually operating the mold frame handle or lever

- Simple structure, low cost, suitable for small batch or trial production

- The labor intensity is high, and the operator needs to have certain experience

2) Automatic opening and closing mold frame

- Using electric or hydraulic drive to achieve automatic opening and closing of the mold

- Improve production efficiency and reduce human error

- Adapt to automated production lines, support the use of robotic arms or gripping devices

3) Pneumatic auxiliary mold frame

- On the basis of manual opening and closing, a pneumatic power assist system is added

- Significantly reduce the labor intensity and difficulty of operators

- Suitable for factories with medium production capacity and the desire to save labor costs

Practical advice :

- If the target is the mid-to-high-end market, it is recommended to prioritize the use of etched or mirror-treated aluminum molds to enhance the appearance and texture of the product

- The recommended number of molds is 1.2 to 1.5 times the number of workstations to meet the needs of mold replacement, maintenance, and flexible production scheduling

- The mold needs to be used with a mold temperature machine to ensure the quality of foaming and setting time

Mold temperature machine

The mold temperature machine is an important equipment for adjusting the temperature of the mold. By circulating heating or cooling medium (usually hot oil or water), the mold is kept within the set constant temperature range to ensure uniform and stable chemical reactions during the foaming process.

Main functions and advantages:

- High temperature uniformity: avoid local overheating or overcooling of the mold, prevent uneven foaming, foaming defects or deformation of the product

- Shorten Foaming and Cooling Down: Accelerate curing speed, improve production rhythm and capacity

- Extend mold life: Constant temperature operation reduces thermal stress and avoids mold cracking or deformation

- Support multi-mold switching: set multi-stage temperature control through the program to meet the process requirements of different molds or products

Technical parameter reference:

- Temperature control range: common 30 ℃~ 150 ℃

- Temperature control accuracy: ± 1 ℃

- Heat medium: hot oil or circulating water (optional according to equipment scale and demand)

- Circulating flow and pressure: Ensure high-speed and uniform flow of heat medium, and respond quickly to temperature changes

Punching Machine (optional)

- Multiple punching methods: mechanical punching, pneumatic punching, or laser punching, choose the appropriate solution according to product requirements

- High degree of automation: supports automatic drilling on the assembly line, ensuring accurate and consistent drilling position and spacing

- Adapt to a variety of materials and hardness: can handle PU foam materials of different densities and thicknesses

- Energy saving and environmental protection: the equipment operates stably, has low noise, and meets industrial safety standards

- High-end soft pillow, improve breathability, reduce stuffiness

- Special function pillows, such as massage or healthcare pillows, optimize air circulation

- Customized products to meet customers’ personalized needs

- Determine whether punching equipment is needed based on product design and Market Positioning

- For brand factories pursuing differentiated competitiveness, punching equipment is an effective tool to enhance product added value

Breaking bubble machine (optional)

- Effectively breaking large bubbles: using high-speed rotating blades or ultrasonic technology to destroy large bubbles in the foam

- Improve pore uniformity: optimize the internal microstructure of foam and enhance the stability of physical properties

- Reduce defect rate: reduce quality problems such as fracture and deformation caused by irregular pores

- Improve product consistency: ensure stable product quality between batches

- Suitable for high-end pillow products with high requirements for foam fineness

- Flexible selection based on production line size and budget

Demoulding system

- Advantages: low equipment investment, flexible operation, suitable for small batch or multi-variety production

- Disadvantages: high labor intensity, low efficiency, susceptible to human factors, poor quality stability

- Advantages: Improve demoulding speed, reduce labor costs, improve product consistency and safety

- Suitable for medium and large automated production lines

pu 메모리폼 베개 생산 라인에 대해 더 알고 싶으시다면 언제든지 저희에게 연락주세요.

플레이리스트

메모리 필로우 생산 라인에 대한 좋은 리뷰

UREXCEED Memory Foam Pillow Production Line has been widely praised by customers for its exceptional efficiency, precise molding capabilities, and reliable performance. With cutting-edge technology and customizable options, it delivers consistent quality while optimizing production processes. Customers highlight its ease of operation, durability, and ability to meet high market demands, making it an ideal solution for businesses aiming to enhance productivity and product quality.

저희는 1년 이상 이 생산 라인을 사용해 왔고, 이는 저희 사업에 게임 체인저였습니다. 내구성 있는 디자인과 안정적인 성능 덕분에 다운타임 없이 높은 시장 수요를 충족할 수 있습니다. 애프터 서비스 지원도 훌륭했습니다.

소피아 응우옌 베트남이 생산 라인 덕분에 최고의 품질을 유지하면서도 빠르게 규모를 확장할 수 있었습니다. 베개는 완벽하게 성형되었고, 기계는 최소한의 유지 관리로 원활하게 작동합니다. 이는 우리 공장에 투자한 최고의 성과입니다.

리암 스미스 영국이 기계로 생산된 베개의 품질은 뛰어납니다. 저희 고객들은 개선 사항을 알아차렸고, 그 결과 저희 매출이 증가했습니다. UREXCEED의 서비스와 기술 지원도 환상적이었습니다!

마리아 곤잘레스 멕시코우리는 메모리폼 필로우 생산 라인의 성능에 감명을 받았습니다. 출력의 정밀도와 일관성은 타의 추종을 불허합니다. 내구성이 뛰어나고 효율적이며 모든 페니의 가치가 있습니다. 팀의 서비스도 훌륭합니다!

올리버 브라운 호주이 생산 라인은 우리가 제품 품질을 개선하고 생산 시간을 단축하는 데 도움이 되었습니다. 신뢰할 수 있고 오래 지속되도록 제작되어 제조 요구 사항에 완벽하게 맞습니다. 우리는 결과에 매우 만족합니다.

아나스타샤 이바노바 러시아 제국젤 필로우 생산 라인이 필요하면 저희에게 연락하세요

메모리폼 필로우 생산 라인은 우리의 제조 공정을 변화시켰습니다. 성형의 정밀성과 품질의 일관성이 뛰어납니다. 작동과 유지 관리가 쉽고 생산 효율성이 기대를 뛰어넘었습니다. 강력히 추천합니다!

존 마르티네즈 미국