실란트 산업을 위한 수요에 따른 PU 디스펜싱 머신 제조

글로벌 접착제 분배 및 밀봉 시장은 다음과 같은 다양한 응용 분야를 포괄합니다. 전자, 자동차, 건설, 의료 산업. 그 중에서도 폴리우레탄은 접착력, 내마모성, 밀봉성이 좋아 대부분의 산업용에 적합하며 자동차 및 전자 산업에서 널리 사용되고 있습니다. 환경 보호 요구 사항이 증가함에 따라 폴리우레탄 밀봉재에 대한 수요도 증가하고 있습니다.

우레엑시드 폴리우레탄 디스펜싱 머신 는 폴리우레탄 재료를 지정된 위치에 정확하고 제어 가능한 방식으로 분배, 주입 또는 적용하는 데 특별히 사용되는 자동화 장비입니다. 폴리우레탄 분배기에는 터치 스크린, PLC 제어 등으로 작동하는 최신 지능형 제어 시스템이 장착되어 있습니다. 사용하기 쉽고 작업자는 생산을 시작하기 위해 디버깅만 하면 됩니다.

실란트 산업에서 폴리우레탄의 전망

실란트 산업에서 폴리우레탄의 적용 전망을 더 잘 이해하기 위해 시장 규모, 성장률, 경쟁 환경 등의 측면에서 데이터 분석을 수행하고, 실제 시장 동향과 소비자 수요를 기반으로 폴리우레탄의 시장 잠재력을 종합적으로 평가할 수 있습니다.

실란트 산업에서의 다양한 단열재의 분포

재료 | 주요 응용 분야 | 시장 침투 |

폴리우레탄(PU) | 냉장 트럭, 냉장 상자, 냉동 창고, 의약품, 식품 및 기타 고급 냉장 체인 애플리케이션 | 35%-40% |

발포 폴리스티렌(EPS) | 저온식품, 로우엔드 콜드체인 포장, 냉장용기 | 25%-30% |

진공 단열 패널(VIP) | 고급 의약품, 생물학적 제품, 초저온 냉장 운송 | 10%-15% |

미네랄울 | 냉장 보관 시설, 산업용 냉장 보관 시설 | 10%-15% |

폴리염화비닐폼(PVC) | 로우엔드 콜드체인 어플리케이션, 식품, 콜드체인 구축 | 5%-10% |

Urexceed의 실란트 산업 파트너는 다양하며 규모도 다양합니다.

당신이 무엇이든 상관없이 자동차 제조업체 및 부품 공급업체, 전기 및 전자 장비 제조업체, 가전 제품 제조업체, 항공기 제조업체 및 항공 부품 공급업체, 군용 통신 장비 및 도구 제조업체, 태양광 패널 제조업체, 풍력 터빈 장비 제조업체, 펌프, 밸브 및 배관 시스템 제조업체, 산업 기계 섀시 제조업체, 다른 브랜드의 부품을 생산하는 소규모 기업 아니더라도, 실란트 산업에 대한 자세한 정보를 알고 싶으시면 저희에게 연락주세요.

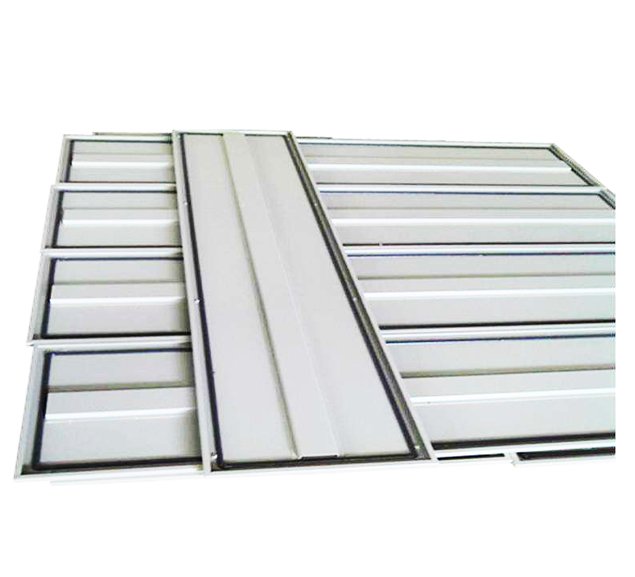

PU 폼 개스킷 디스펜싱 머신

을 위한 실란트 응용 프로그램

자동차 엔진 및 에어컨 부품 개스킷 분배 솔루션

우레엑시드 car air filter gasket dispensing machines are mostly used in air filters, engine hoods and air conditioning systems to improve sealing performance and energy efficiency. Through precise dispensing technology, liquid polyurethane raw materials are applied to the top of the automotive air filter or engine hood and other parts in a specific shape, which plays a role in bonding and sealing to isolate the air.

전기 장비 하우징 실런트 개스킷 주조 솔루션

우레엑시드 sealing strip casting machines are often used to seal electrical control boxes, distribution cabinets, and electronic equipment housings to prevent the ingress of water, dust, and humidity. Because polyurethane foam gaskets have excellent weather resistance, chemical resistance, and mechanical stress resistance. Our casting machines are suitable for sealing needs of complex shapes and irregular parts. It can provide consistent foam coating as required to ensure uniformity of gasket size and quality.

항공기 부품 밀봉 솔루션 맞춤형

우레엑시드 PU 개스킷 디스펜싱 머신 are used to seal cockpit instruments, lighting systems and cabin panels to ensure safety and stability in extreme environments. Polyurethane gaskets are used for waterproof sealing of electrical boxes, sensors and junction boxes. Dispensing machines realize automated processing and improve efficiency. Dispensing machines support the processing of special polyurethane materials such as high temperature resistance, low temperature resistance and corrosion resistance to meet the extreme environmental requirements of the aviation field.

다른 것을 만들고 싶다면 실란트 제품

위의 응용 프로그램이 귀하의 요구 사항을 충족하지 못하는 경우, 우리는 귀하의 제품 제작에 맞는 맞춤형 PU 폼 기계 솔루션을 제공할 수 있습니다.

폴리우레탄 디스펜싱 머신

을 위한 실란트 응용 프로그램

고객의 피드백

PU 기계용 실란트

회사는 고도로 숙련된 원예 조경 전문가 그룹으로 구성되어 있으며, 작은 세부 사항에 많은 관심을 기울입니다. 수년간의 경험을 통해 우리 직원은 귀하의 모습을 아름답게 유지하고 기능하도록 합니다.

회사는 고도로 숙련된 원예 조경 전문가 그룹으로 구성되어 있으며, 작은 세부 사항에 많은 관심을 기울입니다. 수년간의 경험을 통해 우리 직원은 귀하의 모습을 아름답게 유지하고 기능하도록 합니다.

최신 소식

우리의 PU 폼 기계

냉장고 생산 시 발생하는 과도한 거품을 처리하는 방법

During refrigerator manufacturing, the quality of the foam layer is directly related to thermal insulation performance and product stability. Improper control of the foaming time often results in excessive bubbles in the foam layer, bulging on the back, or localized overflow. These issues are largely due to poor internal structural design and production process control […]

냉장고 곰팡이의 발포가 불완전하고 모서리가 충분히 채워지지 않는 일반적인 원인과 해결 방법

If the corners of the refrigerator back panel or inner tank mold are not filled enough or the local foaming is not full during the polyurethane foaming process, it will not only affect the thermal insulation performance of the product, but may also lead to scrapping or rework. The following are common causes of such […]

냉장고의 발포 불량률이 증가하고 있나요?

In the refrigerator production process, the quality of polyurethane foaming is directly related to the thermal insulation performance and energy level of the product. When problems such as poor foaming, uneven foam structure or insufficient filling occur, they are often caused by omissions in process control or equipment parameters. In response to this challenge, the […]