자동차 시트 생산 라인

UREXCEED polyurethane automotive seat production line is designed for efficient and high-precision molding of automotive seats, meeting the stringent requirements of modern automotive industries for comfort, safety, and environmental standards. The full production line includes a 발포기, 금형 및 금형 프레임은 고급 제어 시스템과 통합되어 생산 공정 전반에 걸쳐 최고의 품질 표준을 보장합니다.

UREXCEED의 프로세스 흐름 PU Car Seat Production Line

1단계

2단계

3단계

4단계

5단계

UREXCEED 소개 자동차 시트 생산 라인

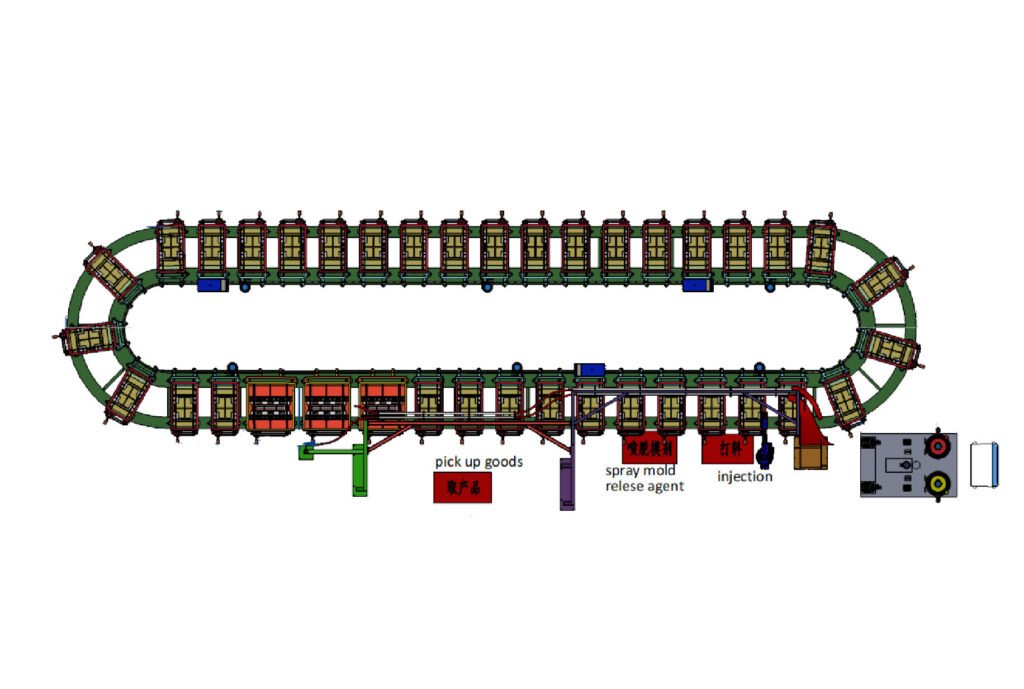

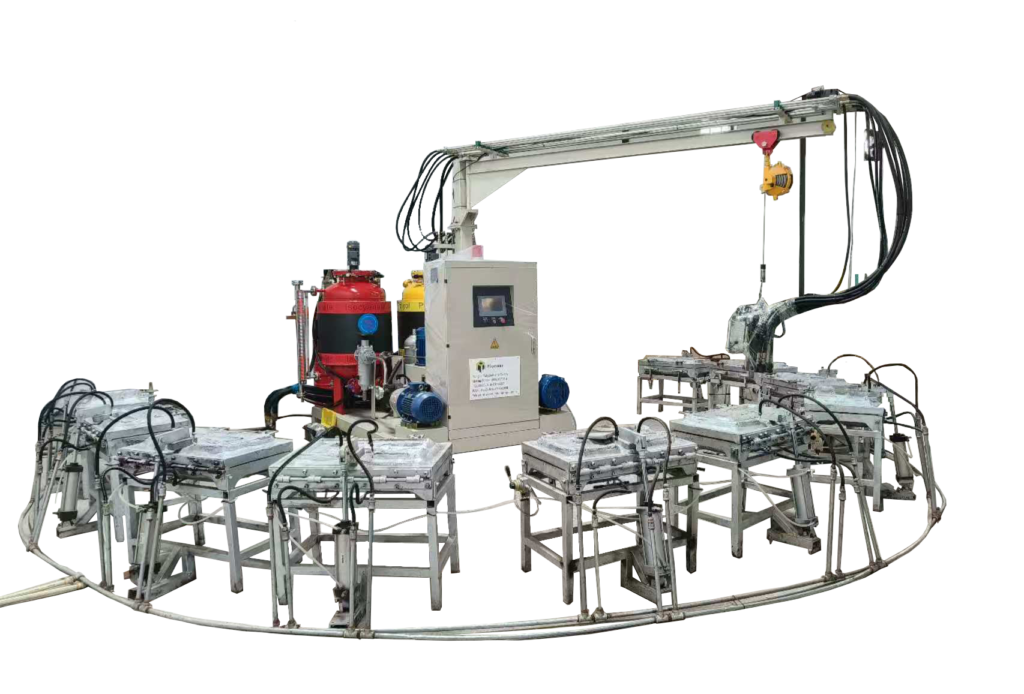

UREXCEED offers a wide range of customizable lines, including rotary lines, carousel lines and banana lines, designed to meet the specific needs of different manufacturing processes. Regardless of the complexity or scale of your production needs, UREXCEED can provide you with the right line to ensure maximum productivity and minimize downtime. Our comprehensive solutions are designed to increase efficiency, reduce operating costs and enhance the overall manufacturing process.

회전 생산 라인

대규모 다단계 자동화 생산에 적합합니다.

응용 분야: UREXCEED 회전 생산 라인은 종종 여러 공정과 연속 생산이 필요한 제품에 사용됩니다. 대량 생산 및 고도로 자동화된 환경에서 특히 효과적입니다.

특징: 높은 유연성으로 회전 생산 라인은 여러 작업 스테이션으로 구성할 수 있습니다. 이는 종종 더 복잡한 제품을 포함하는 장기적이고 고효율적인 생산 작업에 적합합니다.

바나나 생산 라인

특수한 모양이나 곡선 가공 트랙이 필요한 제품을 위해 설계되어 높은 유연성을 제공합니다.

응용 분야: 이 유형의 생산 라인은 곡선 트랙이나 특정 모양이 필요한 공정에 사용됩니다. 특히 유연한 소재를 처리하거나 복잡한 형태의 제품을 제조하는 데 적합합니다.

특징: 적응성이 뛰어난 것으로 알려진 바나나 생산 라인은 독특한 모양이나 각도의 작업물을 처리할 수 있어 다양한 각도나 모양에 맞는 가공이 필요한 제품에 이상적입니다.

원스톱 솔루션 자동차 시트 생산 라인

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

Mold Temperature Control Machine

원료

전체 범위 견적을 원하시면 저희에게 연락하세요

UREXCEED 기계는 유럽 기계보다 30%가 저렴합니다.

자주 묻는 질문 자동차 시트 생산 라인

Uniform foaming is achieved by precisely controlling the raw material mix ratios, injection pressure, and mold temperature. The mold temperature controller plays a key role in maintaining consistent heat distribution, ensuring that the foam expands evenly and cures uniformly.

The mold temperature machine (or mold temperature controller) heats or cools the mold to maintain a constant temperature. This is critical for controlling the foaming reaction, ensuring proper material flow, and ultimately achieving a high-quality, consistent product.

Regular maintenance is essential. It includes:

- Routine inspections and cleaning of molds, nozzles, and mixing heads.

- Calibration of dosing pumps and monitoring of injection pressure.

- Preventive maintenance schedules to reduce downtime and maintain optimal production efficiency.

In case of issues, check the following:

- Raw Material Mix: Ensure the correct ratios of polyol and isocyanate.

- Injection Parameters: Verify that the injection pressure and speed are set correctly.

- Mold Temperature: Confirm that the mold is at the required temperature.

- Release Agent Application: Ensure even application to prevent sticking and surface defects.

Safety and environmental compliance are ensured by:

- Adhering to strict operational protocols and safety guidelines.

- Using eco-friendly raw materials and release agents.

- Implementing proper ventilation and waste management systems to control emissions and protect workers.

Operators receive comprehensive training that includes:

- Detailed operation manuals and on-site training sessions.

- Remote technical support and troubleshooting assistance.

- Continuous updates on best practices to ensure efficient and safe production.

플레이리스트

Transaction Case Of UREXCEED PU Car Seat Production Line

Good Review Of Car Seat Production Line

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

UREXCEED의 생산 라인은 신뢰할 수 있고 효율적이어서 생산량을 늘리고 가동 중단 시간을 줄였습니다. 장비와 지원에 매우 만족합니다.

사라 뮐러 독일우리는 UREXCEED의 시트 생산 라인에 매우 만족합니다. 효율성을 개선하고 고품질을 보장했습니다. 팀은 훌륭한 기술 지원을 제공했습니다. 강력히 추천합니다!

후안 페레스 멕시코UREXCEED의 시트 생산 라인으로 생산 효율성이 30% 증가했습니다. 스마트한 기능으로 오류가 줄어들었고, 서비스도 훌륭했습니다. 매우 만족합니다!

압둘 아지즈 아랍에미리트UREXCEED의 생산 라인은 안정적이고 효율적이며 고도로 자동화되어 있습니다. 오류를 최소화하고 생산을 늘렸습니다. 강력히 추천합니다!"

카를로스 멘도사 스페인이 스프레이 폼 머신으로 훌륭한 결과를 보았습니다. 균일한 코팅을 제공하고 제어하기 쉽습니다.

코팅 기계는 매끄럽게 작동하며 매번 적절한 양의 접착제를 도포합니다. 생산 라인에 큰 도움이 됩니다.

엘리엇 데이비스 운영 이사

A Mexican automotive parts manufacturer sought to improve seat production efficiency and ensure stable product quality. They required a highly efficient and automated polyurethane car seat production line, including a high-pressure polyurethane foaming machine, mold temperature controller, seat molds, and a production line. After multiple discussions, we provided a customized, energy-efficient solution, optimizing key processes such as mold heating, release agent spraying, material injection, and foaming. The client was impressed by our equipment stability, uniform foaming, and one-stop service, leading to a successful order. After installation, we offered remote technical support and on-site training to ensure smooth production. The line is now fully operational, delivering high product yield and helping the client enhance efficiency while reducing costs.

멕시코