Advanced Polyurethane Machinery for Efficient Building Insulation Manufacturing

그만큼 insulation industry is an important part of the construction industry. It mainly includes insulation materials used in building exterior walls, roofs, floors and other parts. Their main functions are to improve the energy efficiency of buildings, pipes, traffics and tanks, reduce energy consumption, improve comfort, and help reduce carbon emissions. Polyurethane (PU) materials have gradually become one of the main insulation materials in the building insulation industry, especially in the fields of energy-saving buildings and green buildings.

우레엑시드 PU 폼 스프레이 기계 are specially designed for construction insulation. Our polyurethane foam spray machines are available in a variety of styles, from low-flow models designed for laboratories to high-power models suitable for large-scale construction projects. From low prices to high prices, our customers can always choose the one that suits them best.

단열 산업에서 폴리우레탄의 전망

단열재 산업에서 폴리우레탄의 적용 전망을 더 잘 이해하기 위해 시장 규모, 성장률, 경쟁 환경 등의 측면에서 데이터 분석을 수행하고, 실제 시장 동향과 소비자 수요를 기반으로 폴리우레탄의 시장 잠재력을 종합적으로 평가할 수 있습니다.

글로벌 단열재 시장 규모 및 성장

시장 조사 보고서에 따르면, 글로벌 건물 단열재 시장 규모는 2023년에 약 1조 4,000억 달러이며, 2028년까지 약 81조 3,000억 달러에 도달할 것으로 예상됩니다. 중국, 미국, 유럽, 인도가 글로벌 건물 단열재 시장의 주요 시장입니다.

단열 산업에서 폴리우레탄의 시장 침투

시장 조사 보고서에 따르면 폴리우레탄은 건물 단열재 산업에서 약 20%-25%의 시장 점유율을 가지고 있으며 향후 몇 년 동안 계속 성장할 것으로 예상됩니다. 2023년 글로벌 건물 단열재 시장 규모는 약 $600억 달러이고 폴리우레탄 시장 규모는 $120억 달러에 도달했습니다. 2028년까지 약 6%-8%의 CAGR로 $200억 달러에 도달할 것으로 예상됩니다.

폴리우레탄 및 기타 소재의 경쟁력 분석

폴리스티렌(EPS)은 여전히 건물 단열 산업의 주류 소재로, 글로벌 시장 점유율 30%-35%를 차지합니다. 록울은 우수한 내화성으로 인해 건물 단열 시장에서 일정한 점유율을 차지하며, 연평균 성장률은 4%-5%가 될 것으로 예상됩니다. 유리울은 열 절연 성능과 흡습성이 좋지 않아 시장 점유율이 낮으며, 연평균 성장률은 2%-3%입니다.

단열 산업에서의 다양한 단열재의 분포

재료 | 열전도도(W/m·K) | 장점 |

폴리우레탄(PU) | 0.020-0.025 | 우수한 단열성능, 경량, 방습, 친환경성, 에너지절약형 건물에 적합 |

폴리스티렌(EPS) | 0.030-0.040 | 저렴한 비용, 편리한 구조, 대규모 응용 분야에 적합 |

XPS(압출 폴리스티렌) | 0.029-0.035 | 방습성 및 내압성이 강하여 지하 및 외벽 단열에 적합 |

암면 | 0.035-0.045 | 우수한 방화 및 방음 성능으로 고층 빌딩 및 산업용 건물에 적합합니다. |

유리솜 | 0.035-0.045 | 우수한 방음 성능으로 특수 환경에 적합 |

Polyurethane Machinery For

격리 응용 프로그램

Polyurethane Machinery Wall Insulation Solution

고효율 벽 단열재인 폴리우레탄(PU)은 뛰어난 단열 성능, 내구성 및 시공 편의성으로 인해 건설 분야의 단열 프로젝트에 널리 사용됩니다. 폴리우레탄 경질 폼은 건물의 외부 또는 내부 벽에 직접 분사하여 연속적이고 매끄러운 단열 층을 형성합니다. 이 방법은 열교 발생을 효과적으로 줄이고 건물의 전반적인 단열 효과를 개선할 수 있습니다.

우레엑시드 폴리우레탄 스프레이 폼 장비 JYYJ-3H는 벽 분무용으로 특별히 설계되었으며 모든 분무기 모델 중에서 가장 경제적입니다. 동시에 고객의 분무 영역, 분무기 두께 등을 확인하여 고객이 원자재 수요를 계산하고 원자재 매칭 솔루션을 제공할 수 있도록 도울 수도 있습니다.

Roofing PU Foam Insulation Solution

폴리우레탄 지붕 단열재는 뛰어난 성능으로 인해 현대 건물에서 에너지 절약을 위한 이상적인 선택이 되었습니다. 특히 복잡한 모양의 지붕 구조에 적합합니다. 표면에 견고한 방수 단열층을 형성하여 열 손실을 효과적으로 차단할 수 있습니다. 건물 에너지 소비를 크게 줄일 수 있을 뿐만 아니라 실내 환경에 편안한 온도 조절 효과를 제공할 수도 있습니다.

사용 중 우레엑시드 폴리우레탄 스프레이 폼 단열 기계, 2성분 폴리우레탄 소재(폴리올과 이소시아네이트)를 비율에 맞게 혼합하여 지붕 표면에 분사합니다. 소재는 빠르게 발포되고 팽창하여 응고되어 연속적이고 기밀한 단열층을 형성합니다. 특정 프로젝트 요구 사항이 있는 경우 건물 특성과 예산에 따라 분무기 솔루션을 선택하고 자세한 시공 계획을 세울 수 있습니다.

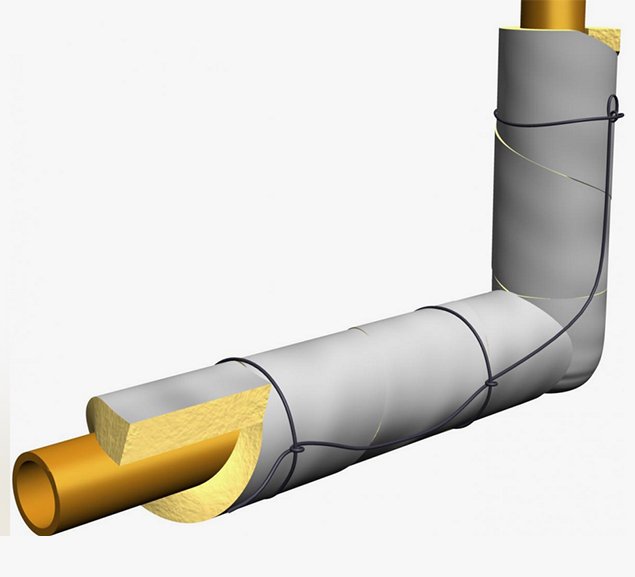

Pipe PU Foam Insulation Solution

고효율 단열재로서 폴리우레탄 폼은 파이프 단열 분야에서 널리 사용되고 있으며, 특히 난방 파이프, 냉동 파이프, 장기간 안정적인 온도를 유지해야 하는 화학 파이프와 같은 프로젝트에서 사용됩니다. 폴리우레탄 폼 단열 파이프는 구조가 간단하고 성능이 뛰어나 단열과 부식 방지를 모두 할 수 있습니다.

Pipe insulation also has several different construction methods. We will recommend different machine solutions based on the customer’s budget and the size of the project. The simplest is to use our 폴리우레탄 폼 스프레이 기계 to spray a large area inside and outside the pipe. You can also use our high pressure polyurethane machine to pour foam into a customized mold to form a pipe shell, and use the pipe shell to cover and reinforce the pipe. No matter which solution you need, we can provide it.

Water Heater PU Insulation Foam Injection Machine Solution

폴리우레탄(PU) 소재는 온수기 생산에 널리 사용되며, 특히 온수기용 단열재 제조에 사용됩니다. 폴리우레탄은 뛰어난 단열성, 경량성, 내구성 및 환경적 지속 가능성을 제공하여 온수기의 에너지 효율을 높이고 서비스 수명을 연장하며 에너지 소비를 줄이는 데 중요한 소재입니다.

온수기의 외부 셸은 일반적으로 폴리우레탄 폼으로 채워져 열 발산을 크게 줄이고 에너지 효율을 개선합니다. 폴리우레탄은 열 손실을 최소화함으로써 온수기가 더 낮은 에너지 소비로 물 온도를 유지할 수 있게 하고 가열 과정에서 열이 유지되는 시간을 연장합니다.

Water Tank Insulation PU Foam Spray Solution

폴리우레탄(PU)은 탱크 제조에 중요한 역할을 하는데, 특히 단열, 내열성, 부식 방지 및 경량 설계와 같은 측면에서 중요합니다.

우레엑시드 폴리우레탄 기계 have applications in surface treatment for tanks, such as spraying, to enhance the appearance and durability of the tank. Surface coatings can improve the UV resistance, corrosion resistance, and stain resistance of the tank’s outer shell, thereby extending its service life and durability. The surface treatment with polyurethane not only enhances the visual appeal of the tank but also improves its functionality.

다른 요구 사항이 있는 경우 격리

위의 응용 프로그램이 귀하의 요구 사항을 충족하지 못하는 경우, 우리는 귀하의 제품 제작에 맞는 맞춤형 PU 폼 기계 솔루션을 제공할 수 있습니다.

Urexceed의 단열재 산업 파트너는 다양하며 규모도 다양합니다.

당신이 무엇이든 상관없이 장식 회사, 건설 계약자, 도시 엔지니어링 회사, 조선소, 개별 건설 팀, 농부, 폴리우레탄 스프레이 기계 임대 회사, PU 폼 스프레이 기계 대리점, 스프레이 폼 기계 임대 아니더라도, 단열 산업에 대한 자세한 정보를 알고 싶으시면 저희에게 연락주세요.

단열 응용 분야

관련된 Polyurethane Machinery

고객의 피드백

Polyurethane machinery for 격리

We’ve been using your polyurethane spray machine on our construction projects, and it’s been performing really well. Easy to operate, consistent spray, and super reliable on-site. It’s made our insulation work faster and cleaner. Great equipment and solid support — thanks!

최신 소식

Of UREXCEED Polyurethane Machinery

냉장고 생산 시 발생하는 과도한 거품을 처리하는 방법

During refrigerator manufacturing, the quality of the foam layer is directly related to thermal insulation performance and product stability. Improper control of the foaming time often results in excessive bubbles in the foam layer, bulging on the back, or localized overflow. These issues are largely due to poor internal structural design and production process control […]

냉장고 곰팡이의 발포가 불완전하고 모서리가 충분히 채워지지 않는 일반적인 원인과 해결 방법

If the corners of the refrigerator back panel or inner tank mold are not filled enough or the local foaming is not full during the polyurethane foaming process, it will not only affect the thermal insulation performance of the product, but may also lead to scrapping or rework. The following are common causes of such […]

냉장고의 발포 불량률이 증가하고 있나요?

In the refrigerator production process, the quality of polyurethane foaming is directly related to the thermal insulation performance and energy level of the product. When problems such as poor foaming, uneven foam structure or insufficient filling occur, they are often caused by omissions in process control or equipment parameters. In response to this challenge, the […]