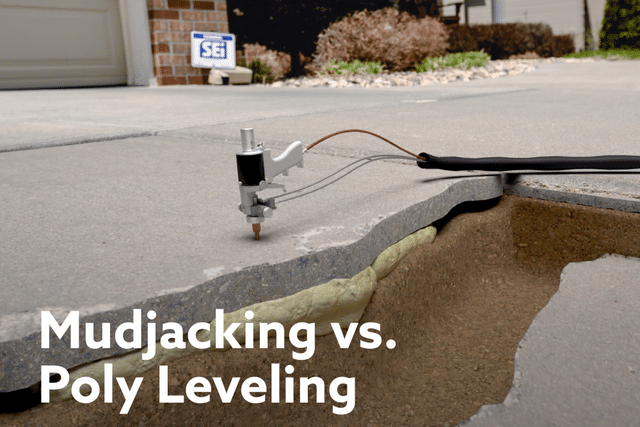

Have you got sunken or uneven concrete slabs? Maybe it’s a warehouse floor causing forklift issues, a settling foundation compromising structural integrity, or a driveway that’s become a trip hazard. These aren’t just eyesores; they’re safety risks and operational headaches that can cost your business time and money. For years, the go-to fix besides complete replacement was often “mud jacking” – pumping a cement slurry underneath. But you might wonder if that heavy, messy process is truly the best solution available today. You need a fix that’s fast, reliable, minimally disruptive, and actually lasts. As someone who has spent years working with the equipment that powers modern concrete repair solutions at UREXCEED, I know there’s a more advanced option: polyurethane foam lifting. How does this newer technology really stack up against the traditional method? Let’s break it down.

When comparing polyurethane foam lifting and traditional mud jacking (also called slab jacking), polyurethane foam lifting often emerges as the superior option for most modern concrete repair needs. While mud jacking uses a heavy mixture of cement, soil, sand, and water, polyurethane lifting uses a lightweight, high-density, expanding polymer foam. This fundamental difference leads to significant advantages for polyurethane: it requires much smaller injection holes (typically 5/8 inch vs 2+ inches for mud), cures incredibly fast (usable within minutes vs days), adds minimal weight to the underlying soil, and offers much greater precision in lifting. Polyurethane foam is also hydrophobic (repels water) and highly durable, resisting erosion and providing a long-lasting repair. While mud jacking might sometimes have a lower initial material cost, the speed, longevity, minimal disruption, and precision of polyurethane lifting often make it the better overall value and technical choice for commercial, industrial, and infrastructure applications.

Understanding that polyurethane often comes out ahead is one thing, but why is that the case? To really grasp the differences and make the best choice for your specific situation, we need to dive deeper into how these two methods compare across several critical factors, from the materials themselves to the long-term performance and cost.

Core Materials: Mud Slurry vs. Polyurethane Foam

The heart of the difference lies in the materials used. They behave very differently once injected beneath the concrete.

- Mud Jacking Material: This is typically a slurry made from a mixture of Portland cement, sand, soil, limestone dust, fly ash, and water. It’s essentially a dense, heavy grout. It relies on hydraulic pressure to lift the slab and then physically hardens over time through cement hydration. It fills voids but doesn’t significantly expand.

- Polyurethane Lifting Material: We use a two-component liquid polymer resin. When these components are mixed, usually right at the injection gun provided by specialized equipment like ours at UREXCEED, they undergo a rapid chemical reaction. This reaction creates expanding, high-density foam that fills voids 그리고 exerts controlled lifting pressure. It’s lightweight but very strong once cured.

Let’s compare the material science based on industry data:

| 매개변수 | Mud Grouting (Mud Jacking) | Polyurethane Grouting (Foam Lifting) |

|---|---|---|

| Grouting Material | Cement + Sand + Water etc. (Heavy) | Two-component Polyurethane Resin (Light) |

| 밀도 | ~1.8-2.2 g/cm³ | ~1.05-1.15 g/cm³ (liquid); Foam varies |

| Reaction Mech. | Physical hardening (cement hydration) | Chemical foaming expansion |

| 경화 시간 | 24-72+ hours for significant strength | 3-15 minutes to solid & traffic ready |

| 팽창 비율 | ~1x (Fills voids, minimal expansion) | Controllable (3x to 25x+ volume increase) |

| Lifting Force | Lower hydraulic pressure (~0.3 MPa) | High expansion force (~5 MPa possible) |

| 정도 | Less precise control | Millimeter-level control (±0.5mm possible) |

This difference in expansion force and controllability is key. Polyurethane’s ability to expand precisely allows for incredibly accurate lifts, even in tight spaces, something much harder to achieve with bulk slurry.

The Construction Process: How Do They Compare?

The way each material is installed significantly impacts disruption, labor, and potential damage to the existing structure.

- Mud Jacking Process: This involves drilling relatively large holes, typically 1.5 to 3 inches (or even 50-100mm) in diameter, through the concrete slab. A cement slurry is then pumped under pressure through these holes using heavy hydraulic equipment. The process can be messy, requiring significant cleanup, and the large holes need patching afterwards, which can be visually unappealing. The weight of the equipment and material can also be substantial.

- Polyurethane Lifting Process: This is a much cleaner and less invasive method. We drill small holes, usually only 5/8 inch (around 16mm) or even smaller (down to 10mm), through the slab. The lightweight liquid polyurethane components are injected through these tiny ports using specialized proportioning pumps and injection guns. The foam expands beneath the slab, lifting it gently. The equipment is often truck-mounted or portable, requiring less site impact.

Here’s a comparison based on a typical 200m² (approx. 2150 sq ft) floor repair scenario:

| Indicator | Mud Jacking | Polyurethane Lifting |

|---|---|---|

| Drill Hole Diameter | 50-100mm (More invasive) | 10-16mm (Minimally invasive) |

| Average Hole Spacing | 1.2 – 1.8m | 0.6 – 1.0m (Allows finer control) |

| Material Per Hole | 20-40 Liters (Heavy slurry) | 3-8 kg (Light foam, expands significantly) |

| 장비 | Heavy hydraulic pumps, large hoses | Specialized proportioning pumps, smaller gun |

| Traffic Waiting Time | Typically 48+ hours | Often just 15-30 minutes |

Real-World Example: I recall a logistics warehouse project in Shanghai. They had around 500m² of sunken flooring causing major issues for their automated guided vehicles. Using polyurethane grouting equipment similar to what we manufacture, the repair team completed the entire job in just 8 hours overnight. Traffic was flowing normally the next morning. Traditional mud jacking would have likely taken 3 days or more, causing significant operational disruption.

Repair Effects and Performance: Which Lasts Longer?

How well does the repair work, and how long can you expect it to last? This is where polyurethane really shines.

- Solidification Time: Polyurethane reacts and cures extremely quickly, often reaching 90% strength within 15 minutes. This means areas can be returned to service almost immediately – a massive advantage for businesses. Mud slurry takes days to cure properly and gain strength.

- Lifting Precision: The controlled expansion of polyurethane allows for very precise lifting, often within millimeters. Mud jacking is a blunter instrument, making fine adjustments difficult.

- Weight: Mud slurry is heavy and adds significant weight to the underlying soil base. If the soil is already weak or poorly compacted, this extra weight can actually contribute to future settling. Polyurethane foam is incredibly lightweight yet strong, adding minimal burden to the soil.

- Durability & Stability: Polyurethane foam is hydrophobic – it repels water and won’t wash away. Its closed-cell structure (often >92% closed cells) makes it highly resistant to moisture penetration and freeze-thaw cycles. Mud slurry, being cement-based, can shrink over time, potentially creating new voids, and it can erode or break down if exposed to moisture, especially in freeze-thaw conditions.

Let’s look at the mechanical properties:

| 성능 | Mud Jacking | Polyurethane Lifting |

|---|---|---|

| 압축 강도 | 15-25 MPa (after 28 days curing) | 5-8 MPa (achieved quickly, flexible load) |

| Impermeability | Poor (can absorb water, erode) | Excellent (>92% closed-cell, waterproof) |

| Freeze-Thaw Resist. | Significant strength loss (>30% after 50 cycles) | No significant deterioration (tested 300+ cycles) |

| Dynamic Modulus | Higher, Rigid | Lower (0.5-1.2 GPa), Adapts to soil shifts |

| Secondary Repair Rate | Reported as high as 38% within 5 years | Typically <5% (often w/ 10+ year warranty) |

The dynamic modulus point is subtle but important. Polyurethane foam has some flexibility, allowing it to better accommodate minor soil movements without cracking or delaminating from the underlying ground, unlike a rigid cement slurry.

Weighing the Cost: Initial vs. Long-Term Value (TCO)

Cost is always a factor. At first glance, mud jacking materials might seem cheaper per unit volume than polyurethane resin. However, you need to look at the Total Cost of Ownership (TCO).

- Initial Costs: Mud jacking might have lower material costs and potentially simpler equipment needs. Polyurethane involves higher-cost chemical resins and requires precise, specialized proportioning equipment (like the high-pressure systems UREXCEED produces).

- Labor & Time: Polyurethane lifting is much faster, requires less labor, and involves far less cleanup. This significantly reduces labor costs and project time.

- Disruption Costs: This is huge for businesses. Polyurethane’s speed means minimal downtime for operations (factories, warehouses, roads). Mud jacking can shut down areas for days. What’s the cost of that lost productivity or business?

- Longevity & Repeat Repairs: Due to its durability and stability, polyurethane repairs typically last much longer than mud jacking. Factoring in the high potential need for repeat mud jacking repairs significantly impacts its long-term cost-effectiveness.

Here’s a simplified cost model analysis based on 2024 market estimates (costs vary significantly by region and project):

| Project Cost Component | Mud Jacking (Estimate/m²) | Polyurethane Lifting (Estimate/m²) | 노트 |

|---|---|---|---|

| Material Cost | ¥120 – ¥180 | ¥350 – ¥600 | PU resin cost is higher per unit |

| Equip. Depreciation | ¥40 – ¥60 | ¥80 – ¥120 | PU requires more specialized equipment |

| Labor & Time | Higher (longer duration) | Lower (much faster) | Less drilling, faster cure, less cleanup |

| Indirect Cost (Downtime) | Potentially High | Minimal to Zero | Huge factor for commercial operations |

| Re-Repair Likelihood | Higher (e.g., 38% in 5yr) | Lower (e.g., <5% in 10yr) | Impacts long-term cost |

| Est. Comprehensive TCO (10yr) | ¥680 – ¥900+ | ¥480 – ¥750+ | PU often 20-35% lower TCO |

While the initial quote for polyurethane might seem higher, when you factor in speed, minimal disruption, and longevity, its TCO is often significantly lower than traditional mud jacking over the life of the repair.

When to Choose Which: Scenario Analysis

While polyurethane is often superior, are there times mud jacking might still be considered?

Prioritize Polyurethane Lifting When:

- Speed is critical: Roads, warehouses, factories needing immediate return to service.

- Precision is required: Supporting sensitive equipment foundations, achieving very specific slab heights.

- Underlying soil is weak or wet: Polyurethane’s lightweight nature avoids overburdening poor soil, and its water resistance is crucial in wet conditions (e.g., high water tables).

- Long-term stability is paramount: Critical infrastructure, permanent building foundations.

- Minimal disruption is needed: Hospitals, retail spaces, residential areas.

- Environmental concerns exist: Polyurethane has lower carbon emissions in production and avoids potential groundwater contamination from cement leachate (some resins are even NSF/ANSI 61 certified for potable water contact).

Consider Mud Jacking Only When:

- The project is very temporary: Short-term fixes where longevity isn’t a primary concern (e.g., temporary structure).

- The underlying soil is exceptionally stable and dry: Less risk of future settlement from added weight or erosion.

- The absolute lowest initial cost is the only driving factor: Even potentially sacrificing longevity and performance (budget < ¥300/m² might force this).

- Precision is not a major concern.

In most modern construction and infrastructure repair scenarios, the technical advantages and long-term value strongly favor polyurethane lifting.

Potential Risks and Limitations

No technology is without potential downsides if not implemented correctly.

Mud Jacking Risks:

- Weight: Can exacerbate problems on already weak soil.

- Shrinkage: Cement slurry can shrink as it cures, creating new small voids.

- Washout: Can erode over time if exposed to water flow.

- Mess & Invasiveness: Large holes, potential slurry spills.

- Lack of Precision: Difficult to control the lift finely.

- Environmental: Cement production has high carbon emissions; slurry runoff can contaminate groundwater (high pH). May require permits for handling potential runoff.

Polyurethane Lifting Risks:

- Requires Skilled Technicians: Proper mixing and injection technique are crucial. Using reliable equipment like ours helps, but operator skill matters.

- Higher Initial Material Cost: As discussed.

- Potential for Over-Lifting: If not monitored carefully, the expansion can lift too much (though experienced techs manage this with monitoring).

- Chemical Handling: Liquid components require proper safety procedures during installation (though cured foam is inert).

Environmental regulations are also tightening. Many regions now restrict or discourage cement-based grouting near waterways or sensitive areas due to leaching concerns (e.g., EPA guidelines in the US). Polyurethane systems, especially closed-cell and certified ones, generally pose far less environmental risk.

결론

So, returning to our question: Polyurethane lifting or mud jacking?

While traditional mud jacking has served its purpose for decades, polyurethane foam lifting represents a significant technological advancement offering compelling advantages in most concrete repair situations. Its core strengths – speed, precision, minimal disruption, lightweight nature, and long-term durability – directly address the shortcomings of older methods.

From our perspective at UREXCEED, providing the specialized equipment needed for polyurethane grouting, we see firsthand how this technology transforms repair projects. The ability to lift slabs with millimeter accuracy, return areas to service within minutes instead of days, and provide a water-resistant, non-eroding, long-lasting solution is invaluable for asset owners and managers.

While the upfront material cost of polyurethane might be higher, the Total Cost of Ownership (TCO) analysis frequently favors polyurethane due to drastically reduced downtime, lower labor costs, and significantly reduced likelihood of needing repeat repairs. Add the environmental benefits and reduced site impact, and the case for polyurethane becomes even stronger. For critical applications demanding performance, longevity, and efficiency, polyurethane lifting isn’t just better – it’s often the smartest investment.