In the cold chain industry, the market share of thermal insulation materials is affected by many factors, including performance requirements, cost control, environmental protection policies, industry standards, etc. So we will introduce in detail the market share of PU, EPS, VIP, Mineral Wool, PVC Foam and XPS in the cold chain industry and their differences in performance, cost, and environmental protection. Through the above comparison and analysis, we believe that you will be more determined to choose polyurethane as the raw material for your production of cold chain products like refrigerators, freezer trucks, insulated boxed and so on.

Analysis of Market Share of Different Materials in the Cold Chain Industry

폴리우레탄(PU)

Polyurethane has gradually occupied an important market share in the cold chain industry due to its excellent thermal insulation performance, light weight, durability and low thermal conductivity.

Polyurethane accounts for about 40%-50% of the market share in refrigerated trucks and cold chain transport boxes, especially in application scenarios that require efficient insulation and light weight, polyurethane is almost the preferred material.

Polyurethane has a high market share of about 35%-45% ~에 cold storage, freezer and refrigerated facilities. Due to its excellent thermal insulation performance, it can achieve good insulation effect at a smaller thickness, especially in high temperature difference environments.

폴리스티렌(EPS)

Polystyrene (EPS) is a traditional insulation material. With its low cost, light weight and easy processing characteristics, it is widely used in low-cost insulation demand scenarios in the cold chain industry.

EPS accounts for about 25%-35% of the market in low-cost cold chain boxes, refrigerated bags and insulated packaging. This material is mainly used for some simpler insulation needs, especially for more economical application scenarios such as food packaging and drug transportation.

In cold chain transportation vehicles, EPS accounts for about 15%-20% of the market. Although the insulation effect is not as good as polyurethane, its low cost advantage makes it still widely used in some transportation scenarios with low temperature requirements.

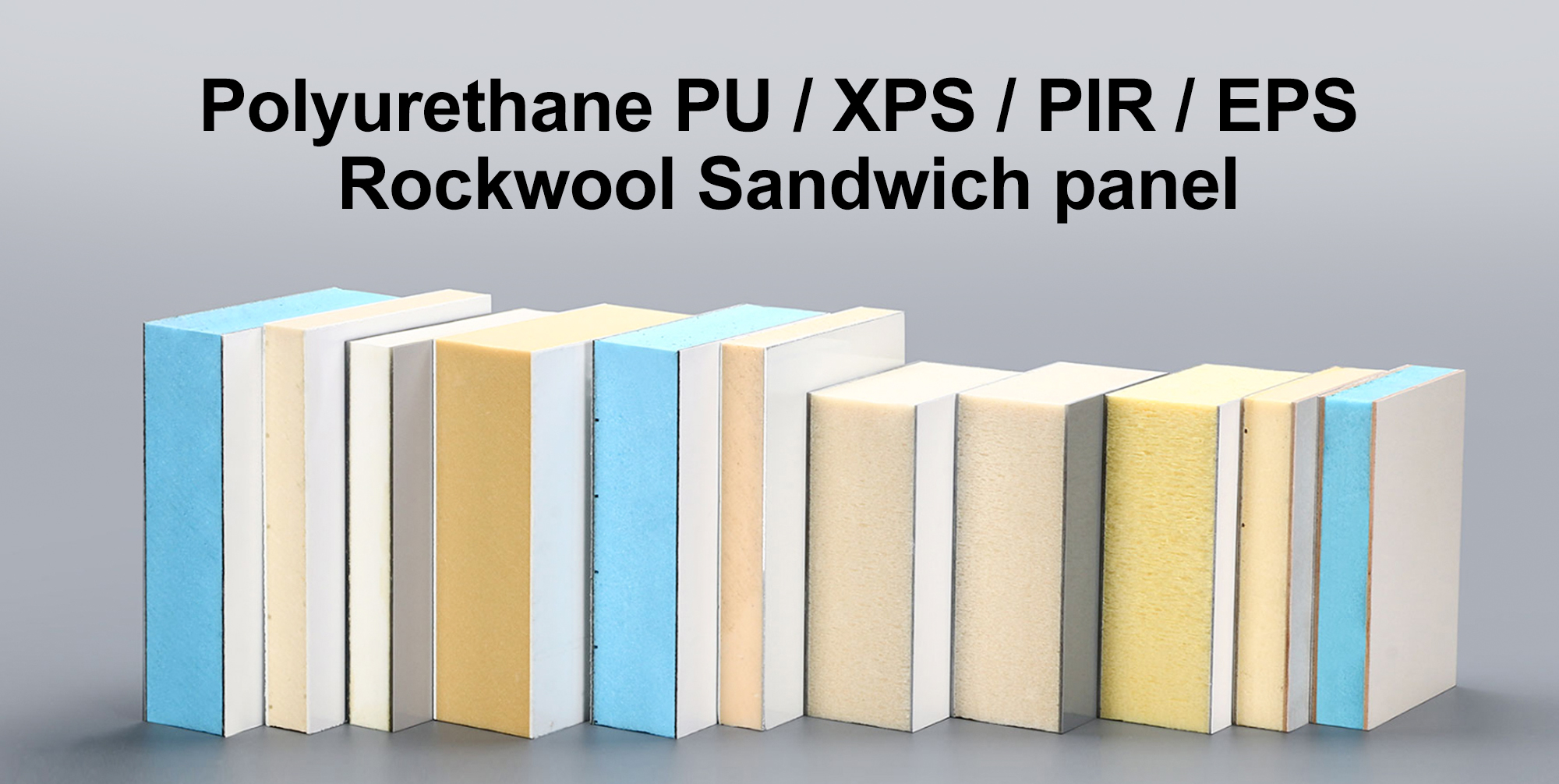

Extruded polystyrene (XPS)

Extruded polystyrene (XPS) is a high-density, closed-cell foam material with low thermal conductivity, high compressive strength and good moisture resistance.

XPS has a certain market share in cold chain transportation, about 10%-20%, and is particularly suitable for applications in cold chain transportation that require high compression resistance, aging resistance and moisture resistance.

에서 wall and floor insulation of cold storage and refrigerated facilities, XPS has a relatively large market share of about 20%-30%. Due to its good compression resistance and moisture resistance, it is widely used in the construction field.

Rock Wool and Glass Wool

Rock wool and glass wool are mainly used in high-temperature insulation and fireproofing requirements. Although they are relatively less used in the cold chain industry, their fireproof performance and high-temperature insulation properties make them still have a certain market share in specific application scenarios.

Rock wool and glass wool are mainly used for wall, roof and floor insulation of cold storage buildings. In construction applications, the market share of rock wool and glass wool is about 10%-15%. This type of material is usually used in cold chain storage facilities with high fireproofing and insulation requirements.

Due to the higher density and poorer insulation performance of rock wool and glass wool, they occupy a relatively small share in cold chain transportation, about 5%-10%.

Other materials (such as vacuum insulation panels VIP, aerogel, etc.)

With the development of new insulation technologies, materials such as vacuum insulation panels (VIP) and aerogel have gained some attention in the field of high-efficiency insulation.

The market share of these new insulation materials is still small, about 1%-5%, because of their high cost, suitable for high-value, special requirements of cold chain transportation, such as medicines, vaccines, electronic products, etc.

Performance Comparison of Polyurethane with Other Materials

Thermal Conductivity Comparison

Thermal conductivity (λ value) is an important indicator for measuring the insulation performance of insulation materials. The lower the thermal conductivity, the better the insulation performance of the material.

재료 | 열전도도(W/m·K) | Temperature Range | 형질 |

폴리우레탄 | 0.020 – 0.025 | -50°C to 120°C | Excellent thermal insulation, durable, long-term insulation performance for various cold chain applications. |

주당 순이익 | 0.035 – 0.045 | -50°C to 70°C | Lower cost but inferior insulation performance compared to polyurethane, suitable for low-end cold chain applications. |

VIP | 0.003 – 0.008 | -70°C to 200°C | Best thermal conductivity but expensive, suitable for high-end cold chain applications. |

미네랄울 | 0.030 – 0.045 | -30°C to 650°C | Excellent at high temperatures but heavier, suitable for building and industrial cold chain applications. |

PVC Foam | 0.035 – 0.040 | -50°C to 75°C | Inferior insulation performance but has some fire-resistant properties, suitable for low-temperature environments. |

Polyurethane (PU) provides excellent thermal isolation performance at both normal and low temperatures, with a thermal conductivity far lower than that of polystyrene foam (EPS) and polyvinyl chloride foam (PVC). Vacuum insulation panels (VIP) offer the best insulation performance, but due to their higher cost, they are mainly used in high-end cold chain industries.

Density and Weight Comparison

Density and weight directly affect the transportation cost and operational convenience of materials during cold chain transportation and installation. Lighter materials help reduce transportation costs and improve work efficiency.

재료 | Density (kg/m³) | Weight (same volume) | 형질 |

폴리우레탄 | 30~60세 | Relatively light, saves transportation costs | Lightweight, durable, suitable for various transport equipment. |

주당 순이익 | 10 – 50 | Extremely light | Cheap, but lower density with inferior insulation performance. |

VIP | 200 – 250 | Relatively heavy | Best insulation but heavier and more expensive due to complex structure. |

미네랄울 | 120 – 200 | Relatively heavy | Higher density, higher transportation costs, suitable for fixed installations rather than mobile equipment. |

PVC Foam | 40~60세 | Relatively light | Suitable for building cold chain, but higher density and narrower application. |

Polyurethane not only provides excellent insulation performance but is also relatively light, making transportation and installation convenient. Compared with other materials (such as mineral wool and vacuum insulation panels), polyurethane has more obvious advantages in transportation and installation.

Cost Comparison

The cost of insulation materials directly affects the overall investment in cold chain transportation and storage systems. Below are the price ranges for different insulation materials (prices may vary by region and specification).

재료 | Cost (USD/m², 50mm thickness) | 장점 |

폴리우레탄 | 6 – 12 | Relatively high cost, but excellent cost-performance ratio and long-term energy savings. |

주당 순이익 | 3 – 6 | Low price, suitable for cost-sensitive low-end applications. |

VIP | 20~40 | Best insulation performance, but very expensive, suitable for high-end markets. |

미네랄울 | 5 – 8 | Moderate cost, suitable for building cold chain and other fixed facilities. |

PVC Foam | 4 – 7 | Lower cost, has some fire-resistant properties, but inferior insulation performance. |

Polyurethane is more expensive, but due to its excellent insulation performance, it can save energy and operational costs in the long run, providing a better cost-performance ratio. EPS, as a low-cost option, is suitable for cold chain applications with less stringent insulation requirements.

Environmental Impact Comparison

With the growing global emphasis on environmental standards, there is an increasing demand for eco-friendly materials in the cold chain industry. Below is a comparison of the environmental impact of various materials.

재료 | 환경 영향 |

폴리우레탄 | Traditional polyurethane foam agents use chlorofluorocarbons (CFCs, HCFCs), which have environmental impact. However, recent developments focus on low GWP (global warming potential) or CFC-free agents to meet environmental requirements. |

주당 순이익 | EPS typically uses inorganic blowing agents, which are relatively eco-friendly, but recycling is difficult. New EPS materials are also exploring eco-friendly blowing agents to reduce environmental impact. |

VIP | VIP does not use chemical blowing agents, and the material itself has minimal environmental impact. However, the energy consumption in production and transportation due to high vacuum technology is significant. |

미네랄울 | Mineral wool has minimal environmental impact and is recyclable. However, it has high energy consumption in production and is relatively heavy, which hinders reducing transportation carbon emissions. |

PVC Foam | PVC foam has poor environmental impact, may release harmful gases during production, and is difficult to recycle. |

Polyurethane materials face certain environmental challenges, especially with the use of traditional blowing agents. However, with technological advancements, the use of low-GWP blowing agents is gradually making it more environmentally friendly. In comparison, VIP and mineral wool perform better in terms of environmental impact, but their disadvantages in price and weight limit their widespread application.

Overall Conclusion

폴리우레탄 remains the most commonly used insulation material in the cold chain industry due to its excellent thermal insulation, moderate density, good environmental performance, and high market penetration. Although it is more expensive, its excellent insulation performance can significantly reduce energy consumption and operational costs in the long run, providing a high cost-performance ratio.

주당 순이익 그리고 엑스포스 are suitable for low-end cold chain applications, with a low price, but its insulation performance is inferior to polyurethane, so it is mainly used in applications where thermal insulation requirements are lower.

VIP offers the best thermal insulation performance, but due to its high cost, it is suitable for high-end cold chain markets, such as biological products and pharmaceutical cold chain transportation.

미네랄울 그리고 PVC foam are suitable for building cold chains and other sectors, but they are relatively heavy, have limited insulation performance, and have poorer environmental characteristics.

Ultimately, choosing the right insulation material requires not only considering performance indicators such as thermal conductivity, density, and water absorption, but also comprehensively evaluating the overall cost-effectiveness of the material based on the needs of the actual application, budget, and safety requirements. Overall, polyurethane remains firmly established in the cold chain industry, especially in areas with higher temperature control requirements, and is still the preferred insulation material.

Last Blog: 폴리우레탄이 콜드체인 산업의 미래인 이유