Advanced PU Foam Machines for Cold Chain

그만큼 콜드 체인 industry involves a lot of product applications, including refrigerated trucks, cold storage panels, cake cabinets, kitchen refrigerators, beverage cabinets, wine cabinets, cigar cabinets, insulation boxes, turnover boxes, etc. The production of these cold chain products is inseparable from polyurethane foaming machines.

우레엑시드 폴리우레탄 발포기 have diversified configurations and high efficiency, support multi-point injection, PLC control systems, and meet the needs of medium and large cold chain products manufacturers.

The Types of UREXCEED PU Foam Machines

There are two main types of polyurethane foaming machines for producing cold chain products, high pressure PU machines 그리고 low pressure PU foam machines. High pressure polyurethane machines can be divided into ordinary high pressure polyurethane foam machines 그리고 cyclopentane system high pressure pu foaming machines. You can choose different models based on your budget, site size and output.

High Pressure PU Machine

우레엑시드 high pressure PU foaming machine adopts high-pressure airless mixing technology. The two liquid materials A(polyol) 그리고 B(isocyanate) are transported to the mixing head through a high-pressure metering pump. Under the impact of high pressure, they are instantly mixed and evenly sprayed out for foaming reaction.

Metering pump: Beijing granis/A2VK-28

Hydraulic pump 10L: HUDE

Mixing head: South Korea SPU 1218-2KV

Material tank: Homemade

Main electrical control system: Omron/schneider/CHINT

Water chilling unit: Zhongcheng

All configurations can be customized according to your requirements.

Self-cleaning L-type High Pressure Mixing Head

Three times repeated mixing, anti-jamming, anti-mixing, mechanical life casting more than 3 million times.

자동 세척 기능

High pressure reflux + self-cleaning design, no need for manual disassembly and cleaning

The Specification of High Pressure PU Foaming Mahcine

이름 | Parameters |

Raw material mixing pressure | 8~16MPa |

Theoretical injection volume | 270~1300g/sec |

Injection time setting range | 0. 5s~999.9s |

Raw material ratio adjustment range | 100:100~100:120 |

Injection metering accuracy | ≤±1% |

Material system working temperature | can be set |

Hydraulic system working temperature | ≤60℃ |

Hydraulic oil working pressure | 10~18 MPa |

Pneumatic working pressure | 0.2~0.8 MPa |

Robot effective working radius | 1800-2500mm |

Robot maximum load | 165kg |

Equipment total electrical power | ≥33.5KW |

Cyclopentane High Pressure Polyurethane Molding Machine

Cyclopentane high pressure polyurethane injection molding machine is a kind of high pressure polyurethane foam equipment specially used for using cyclopentane as foaming agent. It adds explosion-proof system and safety interlock control system on the basis of ordinary high pressure pu foaming machine, and is used to replace Freon foaming agent, which meets environmental protection requirements (such as the Montreal Protocol).

★The injection mixing head can move freely in six directions: front, back, left, right, up and down;

★The mixing head adopts dual proximity switch control to achieve precise injection;

★The inverter soft start and high and low frequency automatic switching are low-carbon, energy-saving and environmentally friendly, and energy consumption is greatly reduced.

The Specification of High Pressure PU Foaming Mahcine

No. | 목 | Technical Parameters |

1 | Applicable Foam Type | 경질 폼 |

2 | Applicable Material Viscosity (25°C) | Polyol/Cyclopentane: up to ~2500 mPa·s |

3 | 사출 압력 | 6–20 MPa (adjustable) |

4 | Repeat Injection Accuracy | ±1% |

5 | Injection Flow Rate (Mixing Ratio 1:1) | 270–1300 g/s |

6 | Mixing Ratio Range | 1:1 to 1:1.5 (adjustable) |

7 | Injection Time | 0.5–99.99 s (accurate to 0.01 s) |

8 | Material Temperature Control Accuracy | ±2°C |

9 | Hydraulic System | System Pressure: 10–20 MPa |

10 | Material Tank Volume | 500 L |

11 | 온도 조절 시스템 | Heating: 2 × 6 kW |

12 | Explosion-Proof Standard | GB36.1-2000 “General Requirements for Explosion-Proof Equipment in Explosive Atmospheres”; Electrical Protection Level: IP54 or above |

13 | Power Supply | Three-phase four-wire, 380V / 50Hz |

Low Pressure Polyurethane Machinery

Polyurethane Low Pressure Foaming Machine is also a device used for polyurethane foam molding. Compared with high pressure PU machines, it adopts mechanical stirring and mixing. 그 equipment structure is relatively simple and the cost is low. It is mainly used for small and medium-scale production or application scenarios that do not require extreme foam fineness.

The low pressure polyurethane foam machine uses a low pressure gear pump to transport the two components A/B (usually polyol and isocyanate) to the mixing head in a set ratio. The mixing impeller in the mixing head mixes them and then sprays them out. The materials foam and solidify on the surface of the mold or workpiece.

재료 탱크

Double interlining heating material tank with insulation outer layer, heart rapidly, low energy consumption.

계량 펌프

High precision JR series gear metering pump (pressure-tolerant 4MPa、speed 26~130r.p.m ), make sure the metering and ration accurate and stable.

No

| 목 | 기술적 매개변수 |

1 | 폼 적용 | Rigid foam |

2 | Raw material viscosity(22℃) | ~3000CPS ISO ~1000MPas |

3 | 주입 출력 | 225-900g/s |

4 | 혼합비 범위 | 100:50~150 |

5 | Mixing head | 2800~5000rpm, 강제 동적 혼합 |

6 | 탱크 용량 | 120L |

7 | 계량 펌프 | A pump: GPA3-63 Type B Pump: GPA3-63 Type |

8 | 온도 조절 시스템 | Heat:2×3.2Kw |

9 | 입력 전원 | Three-phase five-wire 380V 50HZ

|

10 | 정격 전력 | About 12KW |

If you want to more details of our pu foam machines

If the above introduction cannot answer your questions, please call us directly +8613656166310 or leave your contact information and needs. We will try our best to contact you as soon as possible to answer your questions.

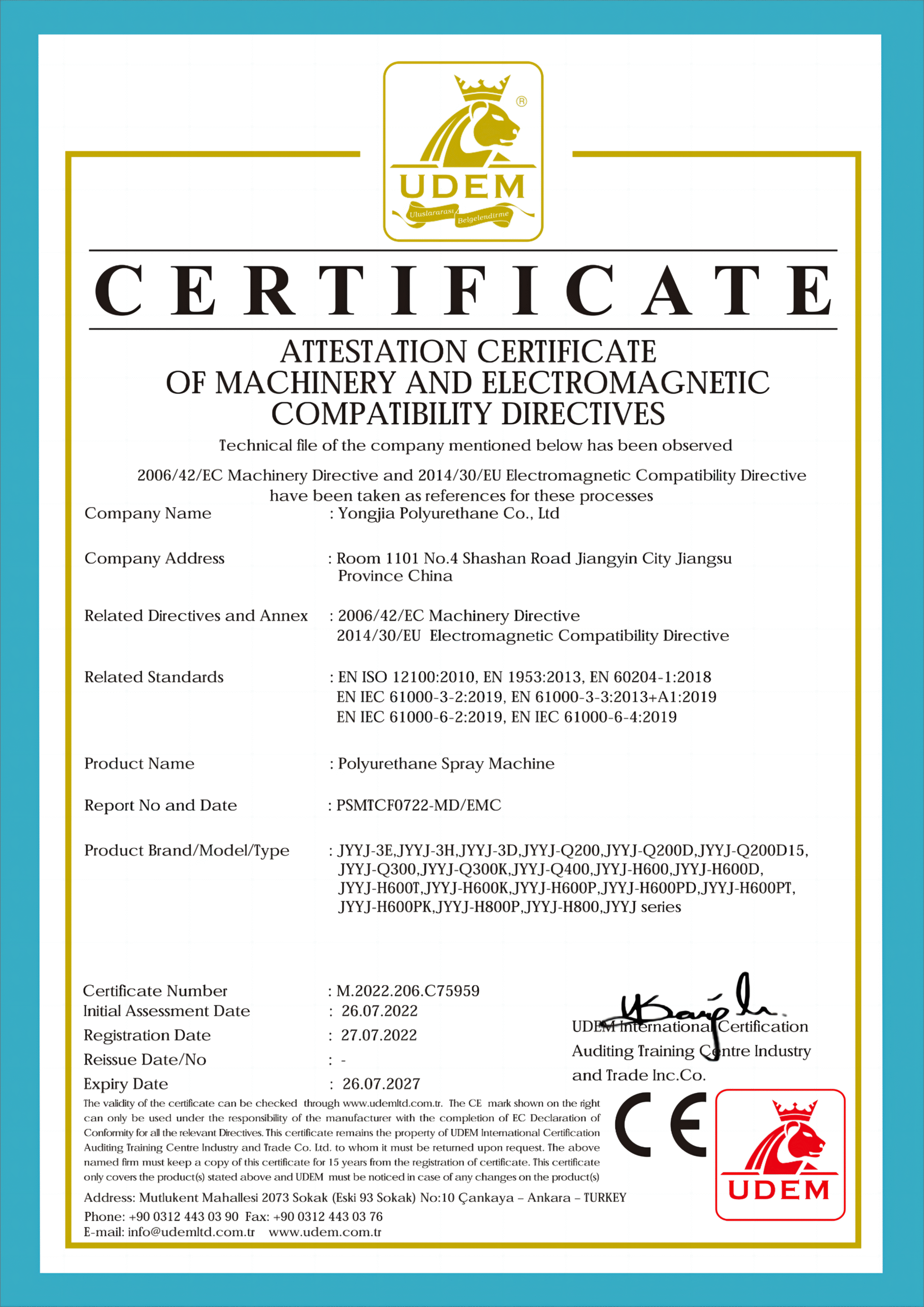

Certifications of

UREXCEED PU Foam Machines

Why Choose

UREXCEED PU Foam Machines

Full Machine Customization

For polyurethane foaming machines, customers can freely choose the machine configuration according to their budget. From Siemens PLC to homemade material tanks, 우레엑시드 can customize the machine according to customer needs.

Experienced Engineers

We have experienced mechanical engineers. In addition to customizing machines according to customer requirements, 우레엑시드 can also provide on-site installation and training services to improve customer learning efficiency and save customer learning time.

One-stop Solution Provider

우레엑시드 can provide a complete set of cold chain production line, from molds to foaming machines to complete assembly lines, to meet all the needs of customers for cold chain production.

24-hour After-sales Serivce

우레엑시드 PU machines have a 1-year warranty and 3-year telephone and video follow-up. 우레엑시드 can provide remote diagnosis services for any problems.

Customers of

UREXCEED PU Foam Machines

UREXCEED has brought high-quality polyurethane foaming machines to customers in more than 100 countries and regions around the world.

FAQ of UREXCEED

PU Foam Machines

Most frequent questions and answers

Yes, UREXCEED is a polyurethane equipment manufacturer with more than ten years of experience. We have our own design team, engineers and sales team.

Our factory is in Jiangyin, Wuxi, about 2 hours’ drive from Shanghai. You can take the high-speed rail directly from Shanghai to Jiangyin, which only takes 1 hour. We can pick you up at the high-speed rail station.

They work on different principles. One relies on high pressure to mix raw materials, and the other relies on mechanical stirring to mix raw materials. The high-pressure machine mixes more fully, has a wider flow range, and has a self-cleaning function. The low-pressure machine is smaller in size and cheaper in price, and can be used to produce some particularly small foam products.

The weight of the product you need to produce, the product output, your budget and the size of the site, etc.

최신 소식

Of UREXCEED PU Foam Machines

콜드체인 산업은 식품, 의약품 및 바이오제약 제품이 운송 및 보관 중에 필요한 저온을 유지하는 데 중요한 역할을 합니다. 식품 안전, 제품 품질 및 환경적 지속 가능성에 대한 소비자 수요가 계속 증가함에 따라 콜드체인 산업은 특히…에서 꾸준한 성장을 경험하고 있습니다.

콜드체인 산업에서 단열재 시장 점유율은 성능 요구 사항, 비용 관리, 환경 보호 정책, 산업 표준 등을 포함한 여러 요인에 영향을 받습니다. 따라서 콜드체인 산업에서 PU, EPS, VIP, 미네랄 울, PVC 폼 및 XPS의 시장 점유율을 자세히 소개합니다.

세계화가 지속적으로 진전되고 소비자의 고품질 식품 및 의약품에 대한 수요가 증가함에 따라 콜드체인 산업은 글로벌 물류에서 점점 더 중요한 역할을 하고 있습니다. 운송 및 보관 중에 정확한 온도 제어를 보장하기 위해 콜드체인 산업은 고성능 단열재에 의존합니다. 다양한…