Линия по производству холодильников

UREXCEED refrigerator production line uses advanced polyurethane equipment and provides a full range of solutions from design to manufacturing, ensuring an efficient and reliable production process to meet your needs for high-quality refrigerators.

О UREXCEED Линия по производству холодильников

Refrigerator Linear Case Foaming Line (Pneumatic Type)

16 Station Refrigerator Linear Box Foaming Line (Motor Type)

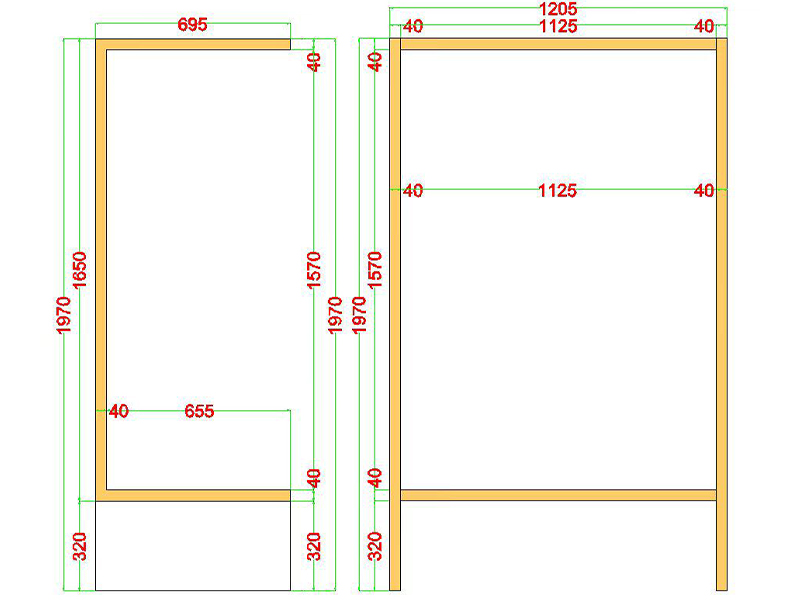

Box specifications | Maximum 2000×2000×700mm Minimum 800×500×400mm |

Curing time | 6~15 minutes |

Filling form | Single gun head one end filling |

Foaming medium | POL mixed HCFC141b, or cyclopentane HFC245fa+ISO |

Number of workstations | Sixteen stations, divided into two lines, eight stations per line |

Production cycle (excluding labor time) | 30 seconds |

Foaming box | The entire line can simultaneously produce eight types of cabinets |

Источник питания | 380V, 50Hz Total power ≤380Kw; control voltage of external components 24V |

Air source | Working pressure ≥0.5MPa O≤0.1m/min |

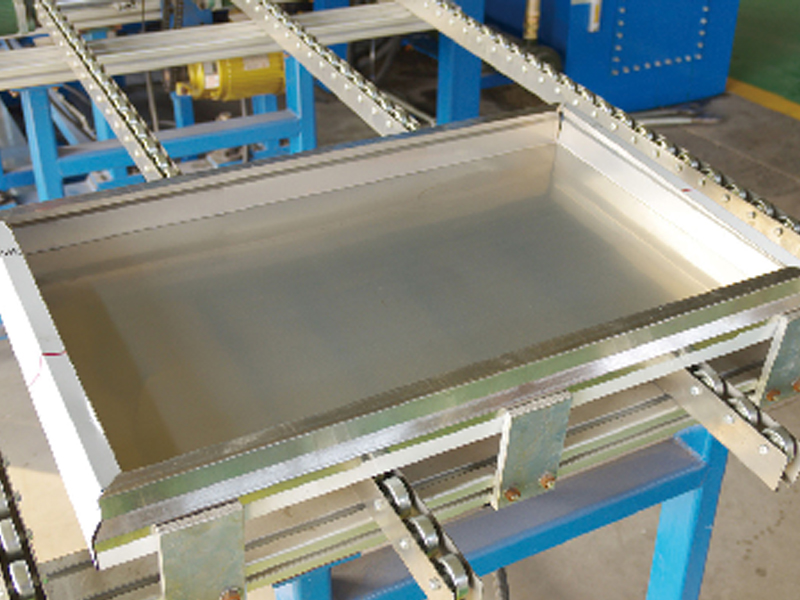

Special Foaming Machine For Supermarket Vegetable Storage Refrigerator

UREXCEED Adopting linear arrangement and water heating form, with automatic bubble blocking function, fixture lifting and lowering adopts hydraulic or pneumatic drive, applicable to different lengths, widths and heights of the box foaming. The production line has the features of small footprint, strong function, high production efficiency, etc. It is suitable for cyclopentane foaming.

Island Cabinet Linear Foaming Specialised Machine (Pneumatic Type)

UREXCEED Adopting linear arrangement and water heating, the fixture lifting and lowering is driven by hydraulic or pneumatic, applicable to the foaming of boxes of different lengths and heights. The production line is characterised by small footprint, strong function and high production efficiency, and is suitable for cyclopentane foaming.

Свяжитесь с нами для получения полной сметы

Машины UREXCEED на 30% дешевле европейских машин

Поток процесса UREXCEED PU Refrigerator Production Line

Шаг 1

Шаг2

Шаг3

Шаг4

Шаг5

Шаг6

Шаг7

Комплексное решение Of Refrigerator Production Line

UREXCEED offer a comprehensive, one-stop solution for refrigerator manufacturing, encompassing product technical research and development support, factory planning and electromechanical engineering contracting, manufacturing and testing equipment production, and customized component supply. Our flexible and efficient production lines can handle various products on the same line, allowing model changes within the production cycle to ensure high-efficiency manufacturing.

Машина для производства пены

Форма

Сырье

Bending Machine

Single Station Moulding Machine

Свяжитесь с нами для получения полной сметы

Машины UREXCEED на 30% дешевле европейских машин

Часто задаваемые вопросы Of Refrigerator Production Line

Modern refrigerator production line usually adopts highly automated equipment, including automatic assembly, welding and inspection systems, to improve production efficiency and product quality.

Advanced production line design allows for the production of different models of refrigerators on the same line and model switching within the production beat to ensure efficient production.

Long-term reliable operation of the production line can be ensured through regular maintenance and the use of high-quality equipment and components.

Modern production lines often adopt energy efficient designs and technologies to reduce energy consumption and minimise the impact on the environment.

Depending on the specific needs of the customer, many suppliers offer customised design and configuration of production lines to meet different production requirements.

Reliable suppliers usually provide comprehensive after-sales services, including regular maintenance, technical support and spare parts supply, to ensure that the production line continues to operate efficiently.

Lead times and commissioning times depend on the complexity of the line and the specific needs of the customer, and are usually specified in the contract.

In order to ensure the safe and efficient operation of the production line, the operators usually need to receive professional training, and the suppliers usually provide appropriate training services.

The payback period depends on factors such as the cost of the line, productivity and market demand, and requires a detailed economic analysis.

Transaction Case Of UREXCEED Refrigerator Production Line

Good Review Of Refrigerator Production Line

UREXCEED refrigerator production line has been implemented in several countries and regions, receiving consistent positive feedback from customers. Clients have reported significant improvements in production efficiency, product quality, and reduced energy consumption. The production lines are also highly flexible, capable of handling different refrigerator models. We continuously optimize and innovate our technology to provide the most competitive solutions.

The Urexceed refrigerator production line has greatly improved our production efficiency. The production cycle has shortened, and the quality has been significantly enhanced. We are very satisfied with this cooperation.

Ахмед AlgeriaI am extremely pleased with the solution provided by Urexceed. The production line is highly efficient, and the stability and performance of the equipment exceeded my expectations.

Maria ИспанияUrexceed's technical team is highly professional. The production line fully meets our needs. The flexibility and energy-saving design are especially good, helping us reduce operating costs.

John СШАThe Urexceed refrigerator production line exceeded our expectations. The equipment's quality and innovation are exceptional, helping us become more competitive in the market.

Luca ИталияThe installation and commissioning of the production line went smoothly. Urexceed's team is very professional, and the service attitude was excellent. We are very satisfied with this production line.

Olga РоссияThrough our partnership with Urexceed, we have achieved a significant boost in production efficiency. The production line runs smoothly, and the after-sales service is timely and professional.

Mohammed Египет

Urexceed provided a complete refrigerator production line solution for a manufacturer in Algeria, covering everything from design and equipment manufacturing to installation and commissioning. The solution significantly improved production efficiency and product quality, while also reducing energy consumption and shortening production cycles. Urexceed customized the production line to meet the customer’s needs, ensuring flexibility for different refrigerator models. The professional team also conducted training to ensure smooth operations. The successful project enhanced the customer’s competitiveness in the local market, strengthening their brand presence. Urexceed’s expertise and service earned the customer’s trust, leading to a long-term partnership.

Algeria