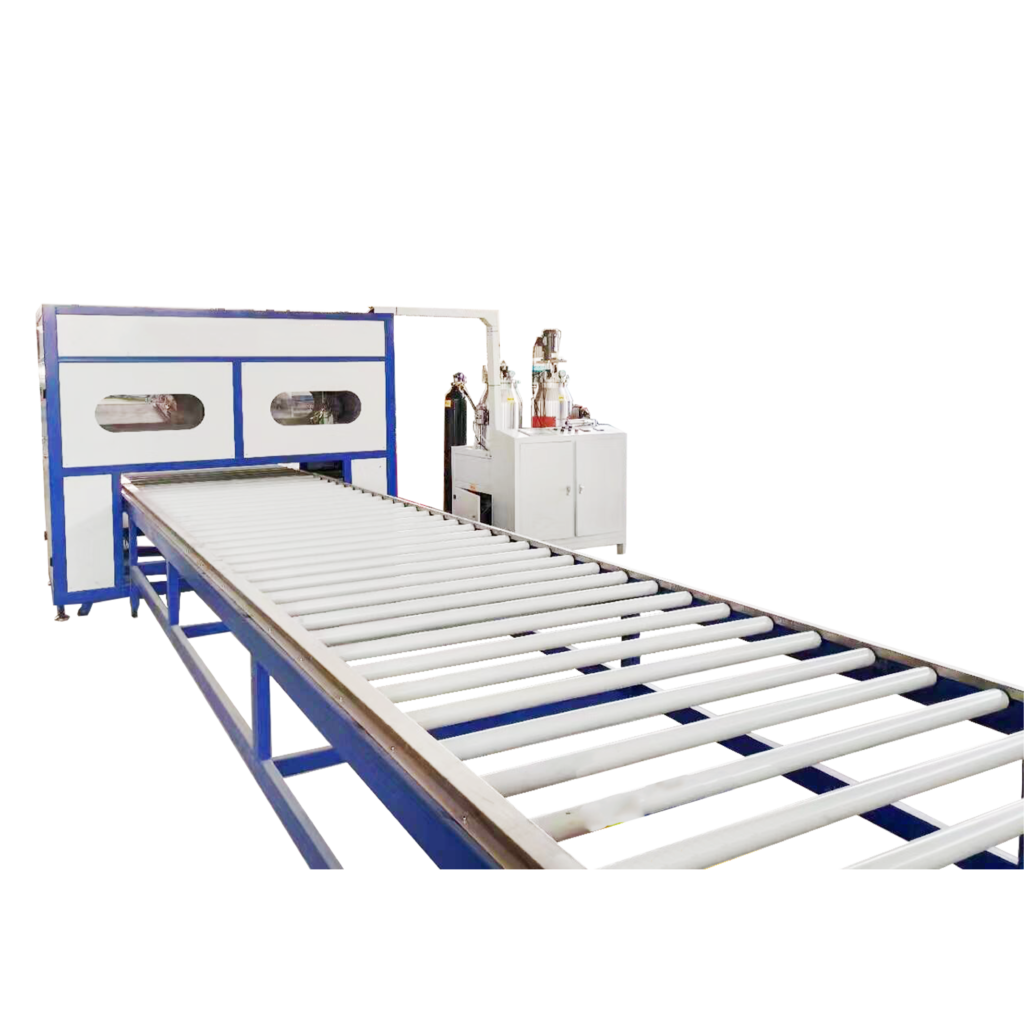

Машина для нанесения клея

- Высококачественное оборудование

- Удаленный мониторинг и диагностика

- Поддержка учета и оптимизации рентабельности инвестиций

- Профессиональное послепродажное обслуживание

Классификация клеенаносящей машины UREXCEED

UREXCEED Машина для нанесения клея отличается высокой точностью, простотой эксплуатации и широкой применимостью. Она значительно повышает эффективность производства и качество продукции, позволяя точно контролировать слой клея, удовлетворяя при этом потребности крупносерийного производства. Подходит для различных материалов и типов клея в различных отраслях промышленности.

UREXCEED

Автоматическая машина для нанесения клея

UREXCEED

Оборудование для ручного нанесения клея

Оборудование для ручного нанесения клея UREXCEED — это простое в эксплуатации устройство, подходящее для мелкосерийного или персонализированного производства. В отличие от автоматических производственных линий, ручная машина для нанесения клея на изделия использует ручное управление. Операторы могут регулировать количество клея и площади покрытия в соответствии с формой изделия и конкретными требованиями к покрытию, что обеспечивает гибкость для различных процессов и спецификаций изделий.

Ручные дозаторы герметика обычно имеют простую конструкцию, просты в обслуживании и требуют меньших первоначальных инвестиций, что делает их идеальными для малых и средних предприятий или научно-исследовательских лабораторий. Они подходят для мелкосерийного производства, изготовления образцов и покрытия поверхностей сложной формы.

Хотите узнать больше о технических характеристиках оборудования для нанесения герметика?

Машина для нанесения клея UREXCEED

Равномерное покрытие для стабильного качества продукции

Дозатор клея обеспечивает равномерное нанесение клея на поверхности продукта, что имеет решающее значение для отраслей, требующих высоких стандартов качества. В таких секторах, как упаковка, электроника и мебель, равномерное покрытие имеет решающее значение для поддержания прочности адгезии, эстетичного внешнего вида и долговечности. Равномерное нанесение предотвращает несоответствия и обеспечивает качество продукта, делая машины высоконадежными для массового производства.

Машина для нанесения клея UREXCEED

Универсальность с различными клеями

Машины для нанесения клея могут работать с широким спектром клеев, включая полиуретан, эпоксидные смолы, акрилы и другие, обеспечивая превосходную гибкость. Такая адаптивность позволяет производителям переключаться между различными типами клея по мере необходимости в зависимости от конкретных требований к продукту. Например, в упаковке могут потребоваться быстроотверждающиеся клеи, в то время как в электронике могут потребоваться высокотемпературные или водостойкие клеи. Такая универсальность гарантирует, что машины для нанесения клея идеально подходят для различных промышленных применений.

Машина для нанесения клея UREXCEED

Простота обслуживания и очистки, сокращение времени простоя

Машины для нанесения клея спроектированы для легкой разборки и очистки, что сводит к минимуму время простоя для обслуживания. Возможность быстрой очистки машин помогает предотвратить накопление остатков клея и загрязнение, обеспечивая постоянную производительность на всех этапах производства. Регулярное обслуживание также продлевает срок службы оборудования, снижая частоту поломок и обеспечивая плавное, бесперебойное производство.

Принцип работы Машина для нанесения клея UREXCEED

UREXCEED glue dispensing machine is used to evenly coat liquid adhesives onto the surface of various substrates, widely applied in industries such as electronics, furniture, packaging, and automotive. Its working principle is as follows

01 Поставка клея

Клей хранится в резервуаре для материала и доставляется в дозирующую головку через транспортную систему, например, насосы или трубопроводы. Некоторые машины оснащены системами нагрева для поддержания текучести и стабильности клея.

02 Распределение клея

Клей поступает в дозирующую головку под давлением или гравитацией. Конструкция дозирующей головки обеспечивает равномерное распределение клея с постоянной скоростью и толщиной.

03 Процесс нанесения клея

Подлежащая покрытию подложка движется с постоянной скоростью по верстаку или конвейерной ленте машины. Клей равномерно распределяется по поверхности подложки из дозирующей головки. Машина позволяет регулировать скорость, ширину и толщину нанесения клея в соответствии с конкретными требованиями к продукту.

После нанесения клея подложка переходит в фазу отверждения (путем сушки на воздухе или термического отверждения) для достижения окончательного склеивания или защитного эффекта.

Часто задаваемые вопросы о клеераздаточной машине UREXCEED

Машина для нанесения клея впрыскивает клей или другие клеи в сопло и равномерно распыляет или наносит его на поверхность целевого изделия через сопло. Оборудование обеспечивает равномерное распределение клея и отсутствие отходов за счет точного регулирования расхода, давления распыления и угла распыления клея.

Машина для нанесения клея имеет более высокую точность и эффективность, может реализовать автоматизированное производство, сократить ручные операции и уменьшить отходы клея. Кроме того, она может обеспечить более равномерный эффект нанесения клея и адаптироваться к различным сложным поверхностям и формам.

Количество клея и толщина покрытия могут быть достигнуты путем регулировки системы управления потоком оборудования, давления сопла и скорости распыления. Большинство клеенаносящих машин также оснащены регулировочными устройствами для точного управления в соответствии с производственными потребностями.

Да, клеенаносящий аппарат можно использовать со многими типами клея или адгезивов, включая клей на водной основе, клей на основе растворителя, термоклей и т. д. Выбор подходящей насадки и конфигурации оборудования может обеспечить плавное нанесение клея.

Эффективность производства клеенаносящих машин обычно высока, особенно автоматизированного оборудования, которое может работать непрерывно и сокращать производственный цикл. Эффективность зависит от формы, размера и требований к нанесению клея на изделие.

Да, клеенаносящая машина может быть настроена в соответствии с потребностями клиента. В зависимости от различных сценариев применения и потребностей в нанесении клея можно выбрать различные сопла, системы управления потоком, системы нагрева и системы передачи.

Современные клеевые дозаторы обычно оснащены простым рабочим интерфейсом и автоматизированной системой управления. Оператору нужно только задать соответствующие параметры, и оборудование автоматически завершит процесс нанесения клея. Большинство машин также оснащены функциями автоматической очистки, что сокращает ручное вмешательство.

Регулярно проверяйте и очищайте головки спринклеров, трубы и гидравлические системы, чтобы гарантировать, что оборудование остается в отличном состоянии. Изнашиваемые детали, такие как форсунки и уплотнения, необходимо регулярно заменять. Кроме того, проверяйте клеевую систему на наличие засоров или утечек, чтобы гарантировать качество нанесения клея.

Потребление энергии дозаторами клея обычно низкое, особенно по сравнению с ручным нанесением клея или традиционными методами нанесения клея. Автоматизированное оборудование может значительно сократить потери энергии. Современное оборудование также поставляется с энергосберегающими конструкциями, такими как системы контроля температуры, для дальнейшей оптимизации энергоэффективности.

Системы подачи клея легче очищать, особенно если оборудование оснащено автоматической системой очистки. Операторам нужно только регулярно чистить сопла и трубы, чтобы предотвратить высыхание и засорение клея, а также поддерживать долгосрочную стабильную работу оборудования.

Срок службы систем дозирования клея обычно составляет 8-10 лет, в зависимости от частоты использования оборудования, обслуживания, типа и качества клея. Регулярное обслуживание и очистка оборудования могут продлить срок его службы.

Около 30 дней

В зависимости от степени настройки оборудования и производственного графика срок поставки клеенаносящей машины обычно составляет 4-6 недель. Конкретный срок поставки будет подтвержден на основе размера заказа, конфигурации оборудования и производственного графика.

Да, клеенаносящая машина подходит не только для крупносерийного производства, но и для мелкосерийного. Для мелкосерийного производства оборудование может гибко регулировать объем и скорость распыления, чтобы обеспечить эффективность производства и экономичный расход клея.

Повышение степени автоматизации, оптимизация конструкции сопла, сокращение времени смены формы и автоматическая регулировка расхода клея и давления распыления могут значительно повысить эффективность производства. Кроме того, регулярное техническое обслуживание и ремонт оборудования могут помочь обеспечить эффективную работу вашего оборудования.

Если вас заинтересовала наша клеенаносящая машина, свяжитесь с нами немедленно.

Плейлист

Хороший обзор машины для нанесения герметика UREXCEED

UREXCEED Glue Dispensing Machine has received exceptional feedback for its precision, consistency, and ease of use. Customers from a wide range of industries, including automotive, electronics, packaging, and manufacturing, have praised its ability to apply glue accurately, ensuring strong and uniform bonding every time. Users appreciate the machine’s flexibility, as it can handle various types of adhesives and apply them in different patterns, making it ideal for both small and large-scale production runs. Many customers have also highlighted the machine’s efficiency in reducing waste and improving throughput, thanks to its automated and controlled dispensing system. Overall, UREXCEED Glue Dispensing Machine is valued for its reliability, high performance, and ability to improve product quality while optimizing manufacturing processes.

Эта машина для производства пенополиуретана низкого давления является абсолютным активом для нашего производственного процесса. Мы видим лучшее качество пены и эффективность.

Роберт Смит Технический директорМашина для эластомера очень эффективна, и мы увидели значительное сокращение времени производства. Это надежный и точный инструмент.

Андре Дюпон Старший инженерМашина TPU просто фантастическая! Она проста в использовании и обеспечивает исключительное качество. Мы увидели значительное улучшение в нашем производстве.

Дэвид Ли Руководитель производстваМы увидели отличные результаты с этой машиной для распыления пены. Она обеспечивает равномерное покрытие и проста в управлении.

Машина для нанесения покрытия работает безупречно, нанося ровно столько клея, сколько нужно. Это прекрасное дополнение к нашей производственной линии.

Элиот Дэвис Операционный директорПрименение клеенаносящей машины UREXCEED

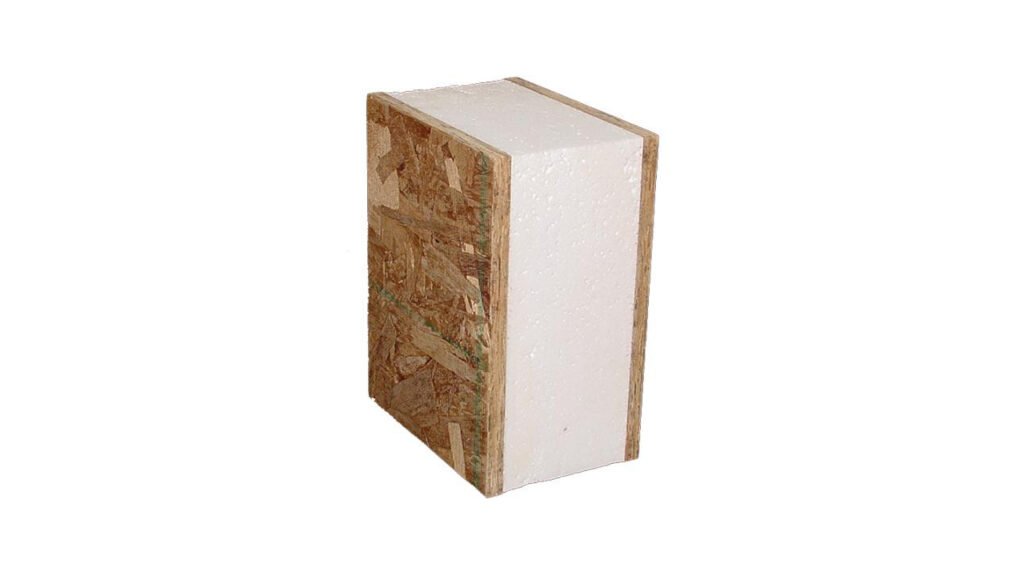

UREXCEED glue dispensing machine is a specialized piece of equipment designed for evenly applying polyurethane gel or liquid to various substrates. It is widely used in industries that require coating, protection, or enhanced performance of products. The machine ensures precise control over the amount, thickness, and uniformity of the coating, guaranteeing consistent surface quality. It is commonly used in automotive, electronics, construction, packaging, and furniture industries.

Панель для холодильной камеры

Сэндвич-панель

Панель для холодильной камеры грузовика

Сертификат на клеераздаточную машину UREXCEED

UREXCEED Машина для дозирования клея создана в соответствии с международными стандартами качества и безопасности, гарантируя высочайшую производительность в различных областях применения. Она сертифицирована по стандарту ISO 9001:2015 для управления качеством, что гарантирует, что каждый этап проектирования, производства и обслуживания соответствует строгим стандартам контроля качества. Кроме того, машина соответствует сертификатам CE и RoHS, что гарантирует соответствие европейским нормам безопасности, охраны окружающей среды и здоровья.UREXCEED также предоставляем полную документацию, включая сертификаты материалов, отчеты о проверках и записи прослеживаемости, что дает нашим клиентам уверенность в том, что клеераздаточная машина соответствует как отраслевым, так и нормативным требованиям для безопасной и эффективной работы.

Машина для производства пенополиуретана высокого давления значительно повысила эффективность нашего производства. Она проста в использовании и чрезвычайно надежна.

Джон Уильямс Менеджер по производству