Dây chuyền sản xuất ghế ô tô

UREXCEED polyurethane automotive seat production line is designed for efficient and high-precision molding of automotive seats, meeting the stringent requirements of modern automotive industries for comfort, safety, and environmental standards. The full production line includes a máy tạo bọt, khuôn mẫu và khung khuôn, tích hợp với hệ thống điều khiển tiên tiến để đảm bảo tiêu chuẩn chất lượng cao nhất trong suốt quá trình sản xuất.

Quy trình hoạt động của UREXCEED PU Car Seat Production Line

Bước 1

Bước 2

Bước 3

Bước 4

Bước 5

Giới thiệu về UREXCEED Dây chuyền sản xuất ghế ô tô

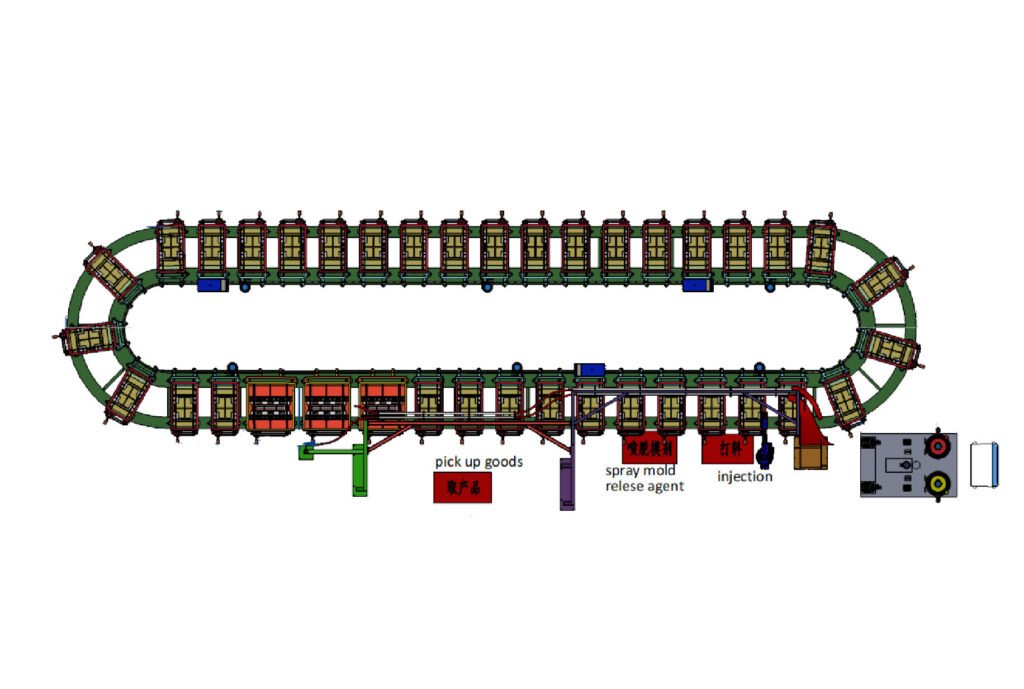

UREXCEED offers a wide range of customizable lines, including rotary lines, carousel lines and banana lines, designed to meet the specific needs of different manufacturing processes. Regardless of the complexity or scale of your production needs, UREXCEED can provide you with the right line to ensure maximum productivity and minimize downtime. Our comprehensive solutions are designed to increase efficiency, reduce operating costs and enhance the overall manufacturing process.

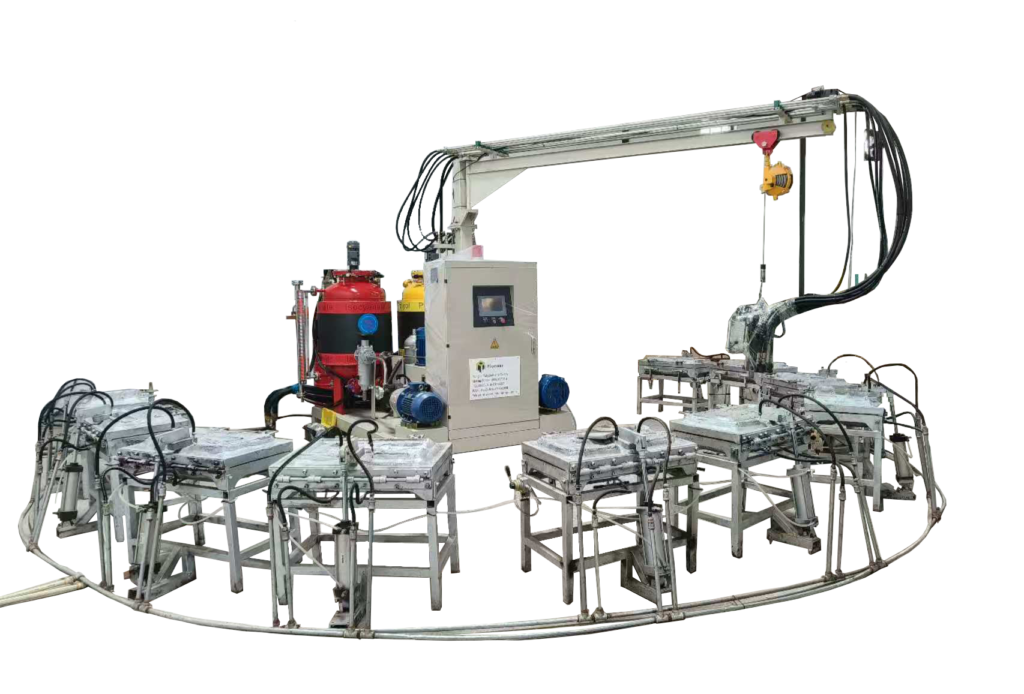

Dây chuyền sản xuất Carousel

Tốt nhất cho sản xuất đơn giản, chu kỳ ngắn với cấu trúc đơn giản

Ứng dụng: Dây chuyền sản xuất UREXCEED phù hợp với các quy trình sản xuất tương đối đơn giản, chẳng hạn như phủ, ép hoặc các hoạt động khác. Nó thường được sử dụng cho sản xuất hàng loạt nhỏ hoặc các sản phẩm có yêu cầu quy trình cụ thể.

Tính năng: Nhỏ gọn và đơn giản, dây chuyền sản xuất dạng băng chuyền lý tưởng cho nhu cầu sản xuất sản phẩm đơn lẻ hoặc sản xuất quy mô nhỏ, chu kỳ ngắn.

Dây chuyền sản xuất quay

Phù hợp cho sản xuất tự động hóa nhiều bước, quy mô lớn.

Ứng dụng: Dây chuyền sản xuất quay UREXCEED thường được sử dụng cho các sản phẩm đòi hỏi nhiều quy trình và sản xuất liên tục. Chúng đặc biệt hiệu quả trong sản xuất hàng loạt và môi trường tự động hóa cao.

Tính năng: Với tính linh hoạt cao, dây chuyền sản xuất quay có thể được cấu hình với nhiều trạm làm việc. Chúng rất phù hợp cho các nhiệm vụ sản xuất dài hạn, hiệu quả cao, thường liên quan đến các sản phẩm phức tạp hơn.

Dây chuyền sản xuất chuối

Được thiết kế cho các sản phẩm yêu cầu hình dạng chuyên biệt hoặc đường gia công cong, mang lại tính linh hoạt cao.

Dây chuyền sản xuất chuối

Được thiết kế cho các sản phẩm yêu cầu hình dạng chuyên biệt hoặc đường gia công cong, mang lại tính linh hoạt cao.

Ứng dụng: Loại dây chuyền sản xuất này được sử dụng cho các quy trình yêu cầu đường cong hoặc hình dạng cụ thể. Nó đặc biệt phù hợp để xử lý vật liệu linh hoạt hoặc sản xuất các sản phẩm có hình dạng phức tạp.

Tính năng: Được biết đến với khả năng thích ứng, dây chuyền sản xuất chuối có thể xử lý các phôi có hình dạng hoặc góc độ độc đáo, rất lý tưởng cho các sản phẩm cần gia công theo góc thay đổi hoặc hình dạng cụ thể.

Giải pháp một cửa Dây chuyền sản xuất ghế ô tô

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

Mold Temperature Control Machine

Nguyên liệu thô

Liên hệ với chúng tôi để có báo giá đầy đủ

Máy UREXCEED rẻ hơn 30% so với máy châu Âu

Câu hỏi thường gặp Dây chuyền sản xuất ghế ô tô

Uniform foaming is achieved by precisely controlling the raw material mix ratios, injection pressure, and mold temperature. The mold temperature controller plays a key role in maintaining consistent heat distribution, ensuring that the foam expands evenly and cures uniformly.

The mold temperature machine (or mold temperature controller) heats or cools the mold to maintain a constant temperature. This is critical for controlling the foaming reaction, ensuring proper material flow, and ultimately achieving a high-quality, consistent product.

Regular maintenance is essential. It includes:

- Routine inspections and cleaning of molds, nozzles, and mixing heads.

- Calibration of dosing pumps and monitoring of injection pressure.

- Preventive maintenance schedules to reduce downtime and maintain optimal production efficiency.

In case of issues, check the following:

- Raw Material Mix: Ensure the correct ratios of polyol and isocyanate.

- Injection Parameters: Verify that the injection pressure and speed are set correctly.

- Mold Temperature: Confirm that the mold is at the required temperature.

- Release Agent Application: Ensure even application to prevent sticking and surface defects.

Safety and environmental compliance are ensured by:

- Adhering to strict operational protocols and safety guidelines.

- Using eco-friendly raw materials and release agents.

- Implementing proper ventilation and waste management systems to control emissions and protect workers.

Operators receive comprehensive training that includes:

- Detailed operation manuals and on-site training sessions.

- Remote technical support and troubleshooting assistance.

- Continuous updates on best practices to ensure efficient and safe production.

Danh sách phát

Transaction Case Of UREXCEED PU Car Seat Production Line

Good Review Of Car Seat Production Line

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

Dây chuyền sản xuất của UREXCEED đáng tin cậy và hiệu quả, tăng sản lượng và giảm thời gian chết. Chúng tôi rất hài lòng với thiết bị và sự hỗ trợ.

Sarah Müller ĐứcChúng tôi rất hài lòng với dây chuyền sản xuất ghế của UREXCEED. Nó cải thiện hiệu quả và đảm bảo chất lượng cao. Đội ngũ đã cung cấp hỗ trợ kỹ thuật tuyệt vời. Rất đáng để giới thiệu!

Juan Perez MêhicôHiệu quả sản xuất của chúng tôi tăng 30% với dây chuyền sản xuất ghế của UREXCEED. Các tính năng thông minh giúp giảm lỗi và dịch vụ tuyệt vời. Rất hài lòng!

Abdul Aziz Các Tiểu Vương quốc Ả Rập Thống nhấtDây chuyền sản xuất của UREXCEED ổn định, hiệu quả và tự động hóa cao. Nó giảm thiểu lỗi và thúc đẩy sản xuất. Rất khuyến khích!"

Carlos Mendoza Tây ban nhaChúng tôi đã thấy kết quả tuyệt vời với máy phun bọt này. Nó tạo ra lớp phủ đều và dễ kiểm soát.

Máy phủ hoạt động trơn tru, luôn phun đúng lượng keo cần thiết. Đây là sự bổ sung tuyệt vời cho dây chuyền sản xuất của chúng tôi.

Eliot Davis Giám đốc điều hành

A Mexican automotive parts manufacturer sought to improve seat production efficiency and ensure stable product quality. They required a highly efficient and automated polyurethane car seat production line, including a high-pressure polyurethane foaming machine, mold temperature controller, seat molds, and a production line. After multiple discussions, we provided a customized, energy-efficient solution, optimizing key processes such as mold heating, release agent spraying, material injection, and foaming. The client was impressed by our equipment stability, uniform foaming, and one-stop service, leading to a successful order. After installation, we offered remote technical support and on-site training to ensure smooth production. The line is now fully operational, delivering high product yield and helping the client enhance efficiency while reducing costs.

Mêhicô