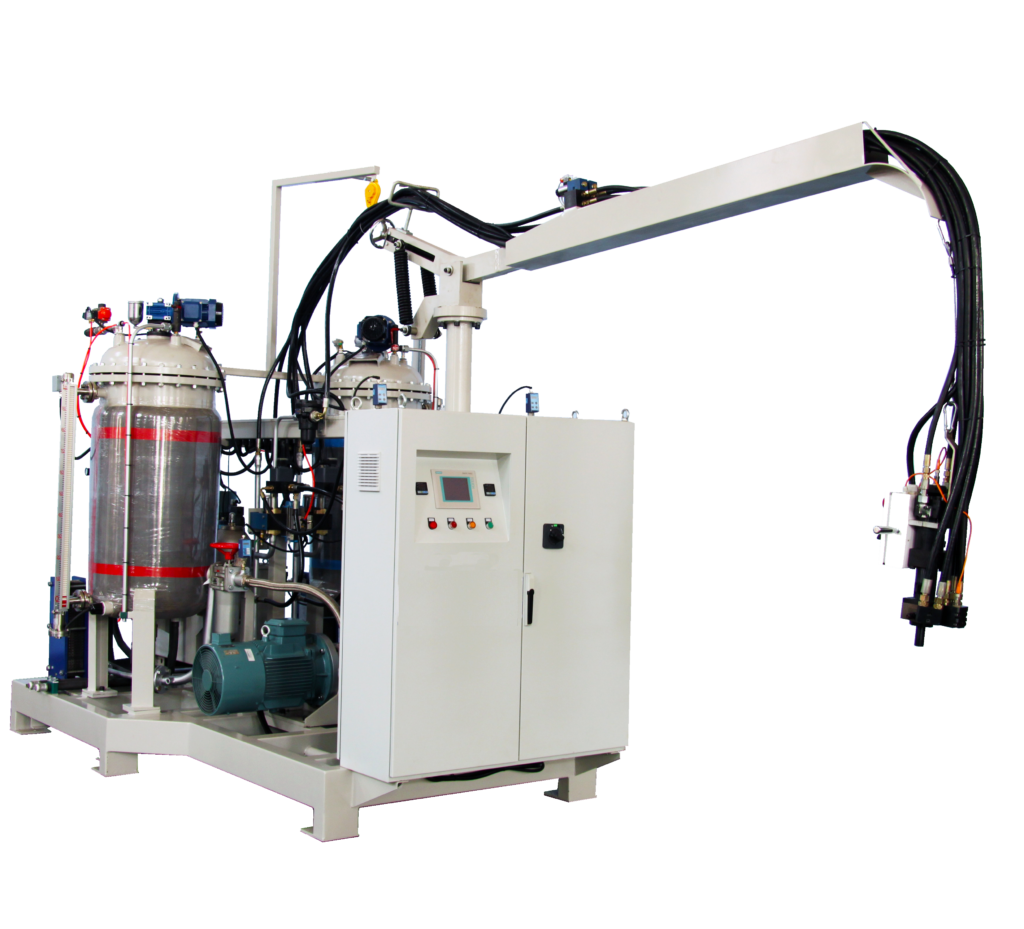

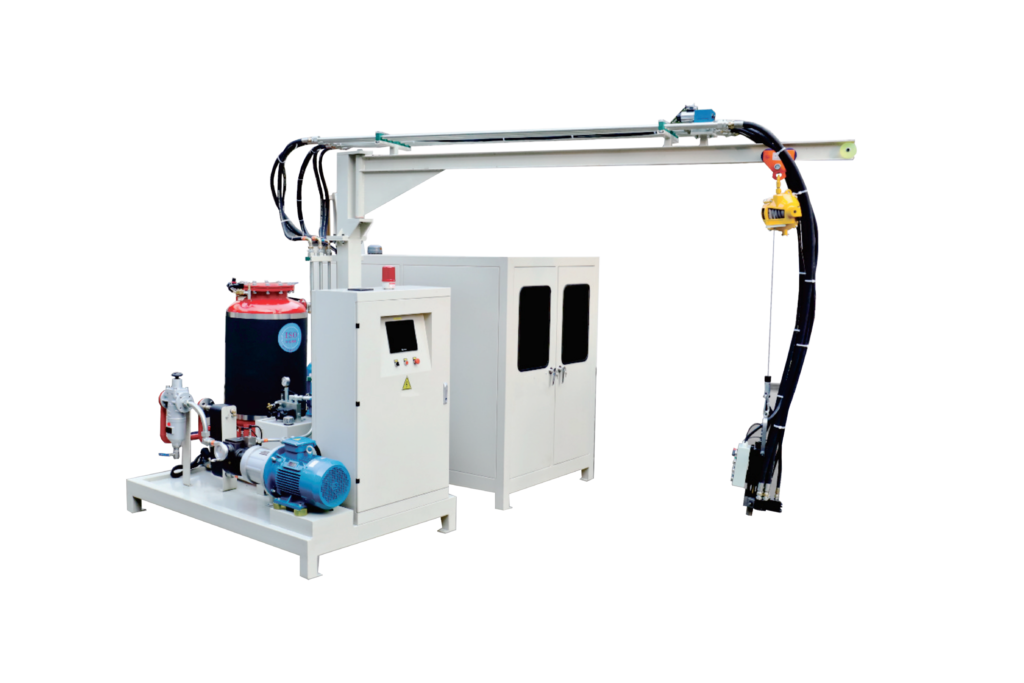

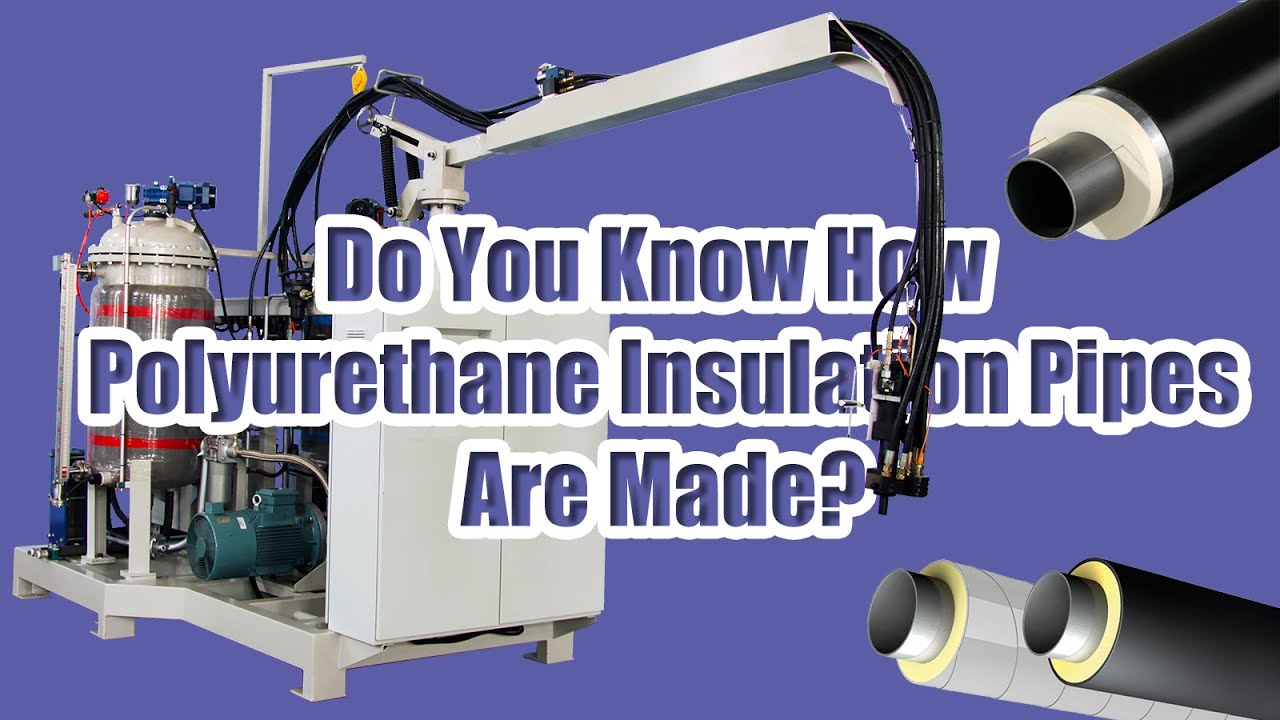

Máy tạo bọt Polyurethane áp suất cao

- The production cycle is as short as 35 days to complete production

- Installation-free design, ready to use right out of the box, saving installation time and cost.

- Designed for easy maintenance, reduced downtime and increased productivity.

- Diversified configurations, three configurations: high, medium and low to meet all customer needs

Classification Of UREXCEED High Pressure PU Foaming Machine

VƯỢT QUÁ

PU Two Component High Pressure Foam Machine

VƯỢT QUÁ

PU Three Component High Pressure Foam Machine

VƯỢT QUÁ

PU Cyclopentane Series High Pressure Foam Machine

| ltem | Technical Parameter |

| Foam application | PU |

| Mixing ratio range | 1:3~3:1(adjustable) |

| Iniection time | 0.5~99.99S(correct to 0.01s) |

| Material temperature control error | ±2° |

| Repeated injection accuracy | 1% |

| Tank volume | 250L |

Want to know more about specification of high pressure pu foam injection machine?

Mixing Head Of High Pressure PU Foam Machine

The high precision mixing head is made of high strength material. The service life is over 1500,000 uses. High pressure injection and impact mixing produces a high level of mixing uniformity. The machine’s self-cleaning function leaves no residue, meaning no cleaning and no maintenance.

Filter Of High Pressure PU Foam Machine

The filters are specifically designed to effectively remove impurities and particles that may arise during the production process. Through a sophisticated filtration system, the raw materials entering the mixing chamber are ensured to be pure and impurities are prevented from affecting the foaming process and final product quality.

Precision Metering System Of High Pressure PU Foam Machine

VƯỢT QUÁ® equipment is equipped with a high-precision metering pump, which can accurately control the flow rate of each component, ensure the accurate proportion of foaming materials, and reduce quality fluctuations caused by proportioning errors.

All machines use international brand accessories such as Siemens, Rexroth, Granlux, etc.

PLC Control System Of High Pressure PU Foam Machine

Adopting advanced PLC control system, automatic cleaning and air flushing, it has stable performance and strong operability. It will automatically identify, diagnose and alarm when abnormal, and display abnormal factors, etc.;

Working Principle Of UREXCEED High Pressure PU FoamingMachine

The working principle of UREXCEED® high-pressure foaming machine involves precisely mixing different raw materials under high pressure and injecting them into molds to form polyurethane foam or other chemical products. The process works as follows:

01 Material Supply

02 Precise Metering and Mixing

03 High-Pressure Injection

After mixing, the liquid is rapidly injected into the mold through a high-pressure injection system. The high-pressure environment causes the raw materials to react and foam quickly, forming a uniform polyurethane foam.

04 Curing and Molding

Once injected into the mold, the polyurethane material begins to cure under high pressure and temperature control, eventually forming the desired product. The curing time and temperature can be adjusted based on specific product requirement

FAQs of UREXCEED High Pressure PU Foam Machine

High pressure polyurethane foam injection machines are suitable for foam production that requires higher density and more precise proportions, and are often used in applications with high quality requirements; while low pressure pu foaming machines are suitable for high-volume, low-cost production.

Yes, the operation of high-pressure foaming machines requires professional training because it involves the control of high-pressure systems and precise proportions. We will provide free training when the machine is delivered and installed

Polyurethane high-pressure foaming machines require regular inspection and maintenance, especially nozzles, seals, pipelines and control systems. It is usually inspected once a month and key components such as seals and nozzles need to be replaced regularly. In addition, the machine failure rate is very low.

Common accessories problems include clogged nozzles, loose seals, pipe leaks, etc. Consumable parts need to be replaced regularly.

Production efficiency depends on the machine configuration and production needs. Usually a high-pressure foaming machine can complete a complete foam injection process in a few minutes. We can customize the automation upon request.

Density and hardness are mainly controlled by adjusting the ratio of components A and B. high pressure polyurethane foam injection machines are generally equipped with precise proportion control systems.

Yes, the equipment can be customized according to customer needs, such as automated process flow (making materials, spraying release agent, opening and closing molds), station switching, formula switching, etc.

The energy consumption of high pressure pu foaming machines is usually related to the production volume and foaming conditions. Modern equipment is often designed with energy efficiency optimization systems that reduce energy consumption.

When cleaning, you need to use special cleaning agents and follow the cleaning cycles and methods recommended by the manufacturer. Regular cleaning of nozzles, pipes and other components will help extend the service life of the equipment. Currently our equipment also supports automatic cleaning of filters.

If you are interested in our high pressure pu foam machine, please contact us immediately

Playlist

Good Review Of UREXCEED High Pressure PU Foam Machine

This high-pressure machine is perfect for our needs. We’ve seen a noticeable improvement in foam consistency and product quality.

Luca Moretti ItalyGreat machine, works flawlessly. Highly recommend for anyone looking to improve their polyurethane foam production.

David Lee UKThe system is very efficient, with easy-to-follow instructions. It saves us both time and costs in production.

Karl Schmidt GermanyApplication Of UREXCEED PU High Pressure Foam Machine

Automotive

Đồ nội thất gia đình

Đồ chơi

Trang trí nhà cửa

Footwear

Chuỗi lạnh

Related Products Of Air Filter Gasket Machine

In addition to UREXCEED high pressure pu foaming machine, we also offer a wide range of high-performance polyurethane equipment, including low-pressure foaming machines, dispensing machines, spray machines, elastomer casting machines,air filter gasket machine and more. These machines are widely used across various industries to meet diverse customer production needs. If you’re interested in learning more about our other equipment, feel free to click to explore further. We are happy to provide detailed product information and technical support.

We have been using this machine for several months now, and the results are consistently excellent. The quality control is precise, and the machine never fails us.

Maria Gonzalez Spain