Máy phun bọt Polyurethane

- 1 machine can meet multiple needs of spraying, coating, filling and others, you only need to replace the spray gun.

- 2 different driving modes (Pneumatic/Hydraulic) are available, with strong power, stable pressure, no seasonal influence, simple operation and convenient movement.

- Using imported international brand cylinders, plunger pumps Và solenoid valves, low failure rate, high kinetic energy conversion rate and low noise.

- 1:1 pressure output, small dynamic and static pressure, high pressure stability, and large raw material output.

Phân loại máy phun bọt PU UREXCEED

VƯỢT QUÁ Máy phun bọt PU is a specialized piece of máy tạo bọt polyurethane used for the application of polyurethan Và polyurea foam through spraying, coating and filling, commonly used in insulation, construction, and industrial applications. Polyurethane foam spray machine is designed to mix and spray two-component polyurethane foam (typically polyol Và isocyanate) onto surfaces to create a thick, high-density layer of insulation or protective coating. The foam expands upon application, providing excellent thermal insulation, soundproofing, and moisture resistance.

In order to meet the different needs of customers, VƯỢT QUÁ has designed several different types of PU foam spray machines. According to the different raw materials, VƯỢT QUÁ polyurethane spray foam equipments can be divided into polyurethane foam sprayers Và polyurea spray machines.

Polyurethane foam sprayers are mainly used to spray or pour polyurethane on the surface or inside of objects that need foam insulation spray, such as walls, floors, etc., such as JYYJ-A-V3, which is our most basic spray foam insulation machine. Polyurea sprayers are mainly used to spray polyurea foam, mainly used for waterproofing and anti-corrosion, such as our JYYJ-H-V6, which is also an economical model.

JYYJ-3H Polyurethane Spray Machine

| Chế độ lái | Khí nén |

| người mẫu | JYYJ-3H |

| Nguồn điện | Một pha 220V 50Hz |

| Công suất sưởi ấm | 7,5KW |

| Đầu ra thô | 2~12 kg/phút |

Máy phun bọt PU JYYJ-H600

| Chế độ lái xe | Truyền động thủy lực |

| người mẫu | JYYJ-H600 |

| Nguồn điện | 3 pha 4 dây 380V 50HZ |

| Công suất sưởi ấm | 22KW |

| Đầu ra nguyên liệu thô | 2~12 kg/phút |

JYYJ-H600P Polyurethane Spray Foam Equipment

| Chế độ lái xe | Truyền động thủy lực |

| người mẫu | JYYJ-H600P |

| Nguồn điện | 3-phase 3-wires 380V 50HZ |

| Công suất sưởi ấm | 26KW |

| Đầu ra nguyên liệu thô | 2~12 kg/phút |

Thiết bị cách nhiệt bằng bọt JYYJ-A-V3

| Chế độ lái xe | Truyền động khí nén |

| người mẫu | JYYJ-A-V3 |

| nguồn điện | 380V 50Hz |

| công suất sưởi ấm | 9,5KW |

| Đầu ra nguyên liệu thô | 2-10KG/phút |

Máy cách nhiệt bọt JYYJ-Q300

| Chế độ lái xe | Khí nén |

| người mẫu | JYYJ-Q300 |

| Nguồn điện | 380V 50HZ |

| Công suất sưởi ấm | 15KW |

| Đầu ra nguyên liệu thô | 2~10 kg/phút |

Máy phun bọt cách nhiệt JYYJ-H-V6

| Chế độ lái xe | Truyền động thủy lực |

| người mẫu | JYYJ-H-V6 |

| nguồn điện | Ba pha ba dây 380V |

| công suất sưởi ấm | 22KW |

| Đầu ra nguyên liệu thô | 2-10KG/phút |

Bơm chuyển

Xi lanh điện

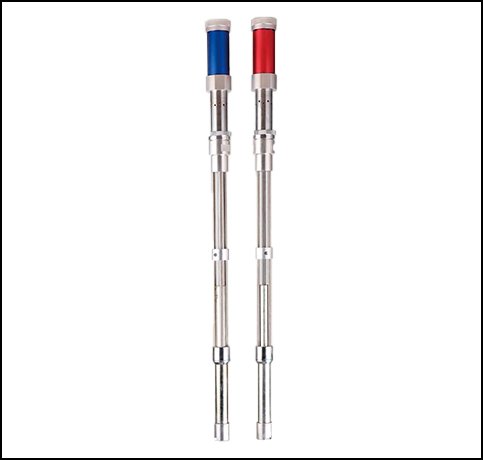

Súng phun

Need more specification of different types UREXCEED PU foam spray machine?

Nguyên lý hoạt động Máy phun bọt PU UREXCEED

01 Cung cấp vật tư

UREXCEED PU spray foam machine is equipped with two separate storage tanks for polyol (polyether) and isocyanate. These materials are delivered to the mixing head via high-precision pumps.

02 Phân phối áp suất cao

UREXCEED pu foam spray machine uses high pressure pumps to deliver the two components to the spray gun in precise proportions. The high pressure ensures efficient delivery of the materials to the spray nozzle.

03 Trộn vật liệu

Bên trong vòi phun, polyol và isocyanate được trộn dưới lực cắt cao. Khi các vật liệu phản ứng hóa học, chúng tạo ra bọt nở nhanh. Hệ thống trộn bên trong vòi phun đảm bảo trộn đều các thành phần, ngăn ngừa bọt không đều hoặc bọt khí.

04 Phun và giãn nở

Bọt hỗn hợp được phun lên bề mặt mong muốn thông qua súng phun. Khi tiếp xúc với bề mặt, bọt bắt đầu nở ra ngay lập tức, tạo thành một lớp đều. Bọt đông lại trong vòng vài phút, tạo thành một lớp rắn, kín khí và cách nhiệt.

05 Đóng rắn và đúc khuôn

Sau khi phun, vật liệu bọt sẽ đông cứng và đông đặc, tạo thành lớp cách nhiệt hoặc lớp bảo vệ bền, liền mạch. Bọt cung cấp khả năng cách nhiệt, chống ẩm và độ bền lâu dài tuyệt vời, lý tưởng cho các ứng dụng trong xây dựng, kho lạnh, ô tô và các ngành công nghiệp khác.

Applications Of UREXCEED PU Spray Foam Machine

Polyurethane spray machines use high-pressure spraying to evenly apply foam materials to target surfaces, providing efficient insulation, thermal protection, and waterproofing. They are widely used to cover large areas quickly, especially in the construction industry, for insulating and waterproofing walls, roofs, and floors.

Building Insulation and Roof Insulation

For building insulation, polyurethane foam is widely used on external walls, roofs, attic and floors. Its excellent thermal insulation properties help save energy and effectively maintain indoor temperature stability by isolating external temperature variations.Cold Chain Logistics and Refrigerated Warehouses

In cold chain logistics and refrigerated warehouses, polyurethane foam is applied for insulation, ensuring temperature control and high energy efficiency for long-term storage.

- Agricultural Building Insulation

Polyurethane foam spraying is used in agricultural buildings such as greenhouses, barns, stables and poultry houses, effectively improving environmental control for optimal growth conditions for crops and livestock.

- Industrial and Workshops

In industrial plants and workshops, polyurethane foam provides a fast and efficient insulation solution, especially for production spaces requiring sealed protection.

Besides these, polyurethane foam is also used to spray in the walls of recording studios, schools, and residential areas. Some people may ask does spray foam insulate sound, and the answer is yes. Polyurethane has excellent acoustic properties, effectively reducing noise transmission. The sound insulation properties of the foam make it especially suitable for noise-sensitive areas. If you need insulation foam and foam insulation machine, liên hệ với chúng tôi!

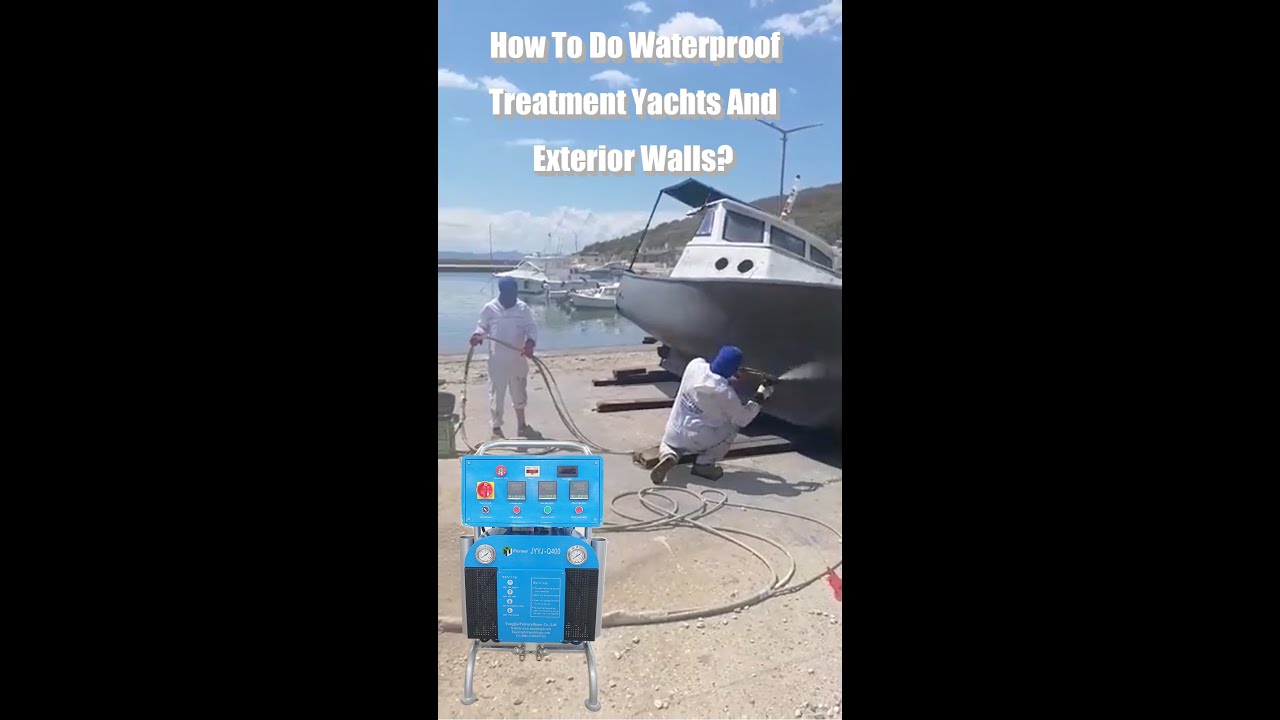

Polyurethane spray machines provide not only thermal insulation spraying but also protective coatings that waterproof, resist corrosion, abrasion, and chemical damage with polyurea. These coatings are widely applied to metal, concrete, wood, and other substrates to improve durability and corrosion resistance.

Pipeline and Tank Protection

Polyurethane coatings are widely used on pipelines and storage tanks in the oil, gas, and chemicals industries, offering corrosion and waterproof protection. These coatings are particularly effective in harsh industrial and marine environments, preventing oxidation, corrosion, and wear.Ngành công nghiệp ô tô

Polyurethane coatings are used on truck beds, chassis, and both interior and exterior parts of vehicles, offering protection against corrosion, wear, and chemical damage.

Marine and Ship Protection

Polyurethane coatings are used to protect ship hulls, boat dock offshore platforms, effectively resisting the harsh marine environment and protecting metal from saltwater, moisture, and corrosion.Industrial Floor Coatings

Polyurethane coatings are used in industrial flooring to provide protection against wear, slipping, and chemical leakage, ensuring long-term durability in factories, warehouses, and workshops.

Of course, the applications of coating are far more than these. Polyurea coating can also be used to spray water parks, swimming pools, building foundations, concrete joints, culverts, steel structures, water tanks, bridges, sculptures, military bases, fountains, aerospace, basements and so on. If you need polyurea Và polyurea coating machine, liên hệ với chúng tôi!

Polyurethane foam’s expansion ability and strength also make it an ideal material for filling voids, supporting structures, and cushioning impacts. It is widely used in applications that require sealing, insulation, and structural reinforcement.

Maritime Buoyancy Equipment

Polyurethane foam is used in the production of flotation devices, life rafts, and other marine equipment, providing lightweight and high-strength buoyancy support.Pipeline and Mine Backfilling

Polyurethane foam is used for void filling in pipeline repair and mining construction, enhancing foundation stability and preventing further settling.

Slab Lifting (Residential, Commercial and Industrial)

Polyurethane foam is widely used for slab lifting in residential neighborhoods, commercial spaces, and industrial facilities, including driveways, sidewalks, garage floors, warehouses, and factory floors. This technology effectively repairs settlement issues, minimizes downtime and maintenance costs, and eliminates the need for structural demolition.

Infrastructure Repair

In infrastructure projects like roads and bridges, polyurethane foam can be used to lift and stabilize settled ground, ensuring traffic safety.

In addition to the conventional insulation foam filling into tanks, water heaters, floats and other products, polyurethane concrete lifting is a popular application for fixing settling concrete. If you need concrete leveling foam or cement leveling machine, liên hệ với chúng tôi!

If your business happens to involve the applications we mentioned or you have other needs, please contact us.

Danh sách phát

Đánh giá tốt về máy phun bọt PU UREXCEED

UREXCEED PU Spray Foam Machine has received outstanding reviews from customers for its performance, ease of use, and efficiency in spray foam applications. Customers in industries such as construction, insulation, and roofing have praised the machine’s ability to deliver high-quality foam with excellent coverage, ensuring superior thermal insulation and energy efficiency. Many users have highlighted its consistent spray pattern and adjustable settings, which provide flexibility for various projects, from small-scale applications to large commercial jobs. The machine’s quick setup, low maintenance, and durable build are also frequently mentioned, allowing businesses to minimize downtime and optimize productivity. Overall, UREXCEED PU Spray Foam Machine is highly regarded for its reliability, precision, and ability to improve both the quality and speed of foam application, making it a top choice for professionals in the spray foam industry.

We’ve been using UREXCEED polyurethane foam spray machine mainly for slab lifting projects. It’s powerful and precise, and our clients love how quickly we can stabilize sunken concrete without a full replacement!

Liam Wilson Site Manager, AustraliaWorking in extreme temperatures here in Canada, we needed a machine that could handle the heat. UREXCEED polyurethane spray machine has exceeded our expectations — reliable, durable, and efficient in every condition.

David Brown Operations Director, CanadaI love the versatility of UREXCEED pu foam spray machine. We use it for insulation, waterproofing, and soundproofing across different projects. It's a great investment for any contractor.

Diego Martinez Project Supervisor, MexicoWe appreciate the eco-friendly polyurethane foam. It's safe for indoor applications and has minimal environmental impact, which is a big plus for our eco-conscious clients.

Amira Tan General Contractor, MalaysiaThe after-sales support team of UREXCEED has been fantastic. They answered all our technical questions and provided excellent training. It made the setup process smooth and hassle-free!

Ahmed Khalil Maintenance Engineer, UAESản phẩm liên quan về máy phun bọt PU UREXCEED

Máy bào bọt Polyurethane

Máy nén khí

Material Drum Heater

Giấy chứng nhận máy phun bọt PU UREXCEED

UREXCEED PU Spray Foam Machine is designed and manufactured to meet the highest international quality and safety standards. It is certified under ISO 9001:2015, ensuring that every phase of production, from design to service, adheres to stringent quality management protocols. Additionally, it holds CE certification, demonstrating compliance with European safety, health, and environmental regulations, ensuring safe operation for users. The machine also complies with RoHS certification, guaranteeing that it meets standards for the restricted use of hazardous substances in electrical and electronic equipment. Full documentation, including material certifications, inspection reports, and traceability records, is provided to ensure full transparency and compliance with industry standards. These certifications give customers confidence in the machine’s reliability, safety, and performance, making it a trusted solution for spray foam applications across various industries.

Câu hỏi thường gặp về máy phun bọt PU UREXCEED

Hiện tại chúng tôi có hai loại khí nén và thủy lực, 220v và 380v. Gần đây, một khách hàng người Mexico đã yêu cầu loại 110V 400v và chúng tôi cũng đang nghiên cứu.

Tính toán dựa trên mật độ của nguyên liệu thô và độ dày của lớp phủ phun. Ví dụ, mật độ là 30kg/m3 và độ dày là 7cm.

Máy bơm vật liệu sẽ bơm nguyên liệu thô vào máy phun, làm nóng chúng đến nhiệt độ cần thiết, sau đó vận chuyển chúng đến súng phun thông qua ống gia nhiệt, trộn đều chúng trong súng phun rồi phun ra ngoài.

A: Đường ống và nguồn điện từ máy tính chủ đến súng đã được kết nối.

Cần thực hiện các kiểm tra sau đây trước khi vận hành:

1. Tất cả các mối nối từ bộ phận chính đến súng không bị rò rỉ không khí hoặc vật liệu,

2. Đảm bảo tách riêng vật liệu A và B trong toàn bộ đường ống đầu vào từ bơm đến súng để tránh làm tê liệt toàn bộ hệ thống.

3. Phải có nối đất an toàn và bảo vệ chống rò rỉ.

4. Khi thiết bị ngừng hoạt động, phải kịp thời tắt hệ thống gia nhiệt và ngắt nguồn điện để tránh làm giảm chất lượng tạo bọt do thời gian gia nhiệt quá lâu.

Mô hình khí nén ít nhất là 0,9Mpa/phút và mô hình thủy lực chỉ là 0,5Mpa/phút.

Nhiệt độ tối ưu 10-25℃

Nhìn chung, chỉ cần vòng đệm được thay thế, chúng tôi sẽ cung cấp cho bạn một số vòng đệm trong hộp công cụ của máy sau.

·Nhiệt độ kho lạnh bảo quản tươi khoảng 5℃, độ dày lớp cách nhiệt là 15cm.

·Nhiệt độ của tủ đông khoảng -20℃, độ dày của lớp cách nhiệt là 25cm.

Cavitation is caused by vapor bubbles forming in the fluid lines due to insufficient fluid pressure or blockages. This can damage pumps and reduce spray quality. To prevent cavitation, ensure proper fluid supply, avoid leaks, maintain correct pressure settings, and regularly clean filters and check hoses for blockages.

Blisters and pinholes often result from trapped air, moisture, or contaminants on the substrate. To troubleshoot:

Ensure the surface is clean and dry before application.

Apply the coating in controlled humidity and temperature conditions.

Use proper spray techniques to avoid excessive air entrapment.

Allow sufficient curing time between coats.

Best practices include:

Regularly clean all parts, especially spray guns and fluid lines.

Check and replace worn seals and filters.

Lubricate moving parts as recommended by the manufacturer.

Store the machine properly in a dry environment.

Perform routine inspections and follow a maintenance schedule.

To resolve spray gun issues:

Leaking: Check seals and tighten connections.

Clogging: Clean the nozzle and filters; flush the system regularly.

Uneven spray patterns: Adjust spray pressure and inspect the tip for damage or wear. Always use manufacturer-recommended cleaning solutions and spare parts.

UREXCEED polyurethane spray machine has completely transformed our workflow. What used to take days now takes just hours. Fast curing, reliable output, and easy to operate — couldn’t ask for more!

James Walker Construction Manager, USA