Polyurethane Casting Machine

- Short production cycle, complete production in 30 days

- Supports MDI and TDI systems

- Equipped with TDI hot air circulation heating to ensure consistent processing and stable results.

- Supports up to 5 color paste systems

- One-stop solution that can provide raw materials, cleaning agents, ovens, operating tables, etc.

- Low noise, low power, energy saving

Polyurethane Casting Machine

Polyurethane casting machine is engineered for the production of PU elastomers. It enables precise metering, stable temperature control, and thorough mixing of components, ensuring consistent product quality. Widely used in casting wheels, rollers, seals, and other high-performance elastomer parts, this machine supports a variety of PU formulations and is essential for efficient, high-accuracy elastomer manufacturing.

Item | Technical Parameter |

Injection Pressure | 0.01-0.6Mpa |

Mixing ratio range | 100:8~20(adjustable) |

Injection time | 0.5~99.99S (correct to 0.01S) |

Tank volume | 250L /250L/35L |

Temperature control system | Heating: 31KW |

Input power | Three-phrase five-wire,380V 50HZ |

Rated power | 45KW |

Want to know more about specification of pu elastomer casting machine?

Pigment System

Mix Head

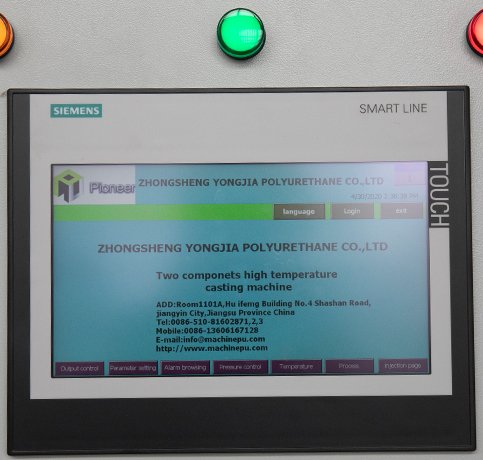

PLC and touch screen human machine interface

Working Principle Of UREXCEED PU Casting Machine

UREXCEED PU casting machine is a specialized device used for producing polyurethane elastomers, widely used in industries such as automotive, footwear, furniture, and electronics. It is designed to precisely mix and inject polyurethane raw materials into molds, allowing for the creation of durable, high-performance products with excellent wear resistance, elasticity, and aging resistance.

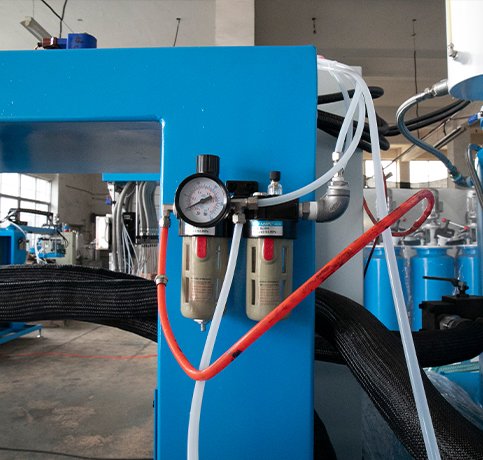

01 Material Supply

UREXCEED PU casting machine is typically equipped with multiple storage tanks for various raw materials, such as polyols, isocyanates, catalysts, and other additives. These materials are delivered to the mixing head through pumps or pipelines.

02 Material Mixing

At the mixing head, the machine uses a high-precision metering system to accurately mix the components in the correct ratios. High-shear mixing technology ensures thorough integration of the raw materials, preventing uneven curing or foaming.

03 Reaction and Casting

After mixing, the materials are injected into molds or casting lines where they undergo a chemical reaction under controlled temperature and pressure. The polyurethane elastomer begins to foam and gradually solidifies. This process can be completed through heating or natural curing, depending on the required product characteristics.

04 ProcessingMolding and Curing

Once the foaming and curing processes are complete, the elastomer material is molded into the desired shape and forms the final product. These elastomer products typically exhibit excellent elasticity, wear resistance, and oil resistance, making them suitable for a range of high-performance applications.

FAQs Of UREXCEED PU Casting Machine

Our polyurethane elastomer machine is capable of producing both soft and hard elastomers, ideal for applications in automotive interiors, footwear, seals, industrial components, and more. The machine supports TDI and MDI systems, allowing you to adjust hardness, elasticity, and wear resistance according to your specific requirements.

Our pu casting machines are capable of low, medium, and high-temperature foaming, suitable for producing polyurethane elastomers with varying degrees of hardness. The technical specifications include maximum pressure, temperature range, and mixing ratio precision. These parameters can be adjusted according to your production needs.

Our polyurethane elastomer machines feature an intuitive control system, making it easy to operate. We provide comprehensive training and detailed user manuals to ensure your team can quickly become proficient in using the machine. For maintenance, we offer regular maintenance suggestions and provide 24/7 after-sales support to ensure the machine stays in optimal condition.

Our polyurethane elastomer machines are compatible with both TDI and MDI systems, and can handle a wide range of raw materials. The machine is designed to be flexible, allowing you to adjust formulas and material inputs as per your specific production requirements.

The price of our pu casting machine varies depending on the specifications and customization options. To provide you with the best competitive pricing, we recommend discussing your specific needs and production goals with our sales team. We will provide a tailored solution and quote accordingly.

We provide a one-year warranty on our polyurethane casting equipments, and our after-sales services include remote technical support, routine maintenance, and spare parts supply. Additionally, we offer training services to ensure your team can operate and maintain the equipment efficiently. Any technical issues will be handled by our support team promptly.

Our elastomer machines are equipped with multiple safety features, such as overload protection, temperature control, and safety locking systems. All machines meet international safety standards. We also provide safety operation guidelines to ensure the safe use of the equipment.

Our casting machines are designed with energy-saving technology to reduce energy consumption, which helps lower operational costs. We also optimize machine configurations based on your production needs to maximize energy efficiency while maintaining high-quality production standards.

Yes, we offer customized solutions for our polyurethane elastomer machines. Whether it’s the size, configuration, functionality, or compatibility with specific raw materials, we can design a machine tailored to your exact production requirements.

If you are interested in our polyurethane casting equipment, please contact us immediately

Playlist

Good Review Of UREXCEED Foam Machine

UREXCEED PU Casting Machine has earned exceptional reviews for its precision, versatility, and durability in producing high-quality polyurethane castings. Customers in industries such as automotive, furniture, and construction have praised the machine for its ability to deliver uniform and consistent results, even for complex and intricate molds. Users appreciate its efficiency in reducing material waste and enhancing production speed, making it a cost-effective solution for high-volume manufacturing. The machine’s user-friendly controls and easy maintenance features have also been highlighted, allowing for smooth operation and minimal downtime. Many clients have noted UREXCEED PU Casting Machine’s ability to handle various polyurethane formulations, offering flexibility for different applications. Overall, UREXCEED PU Elastomer Casting Machine is highly regarded for its reliability, robust performance, and its ability to improve production efficiency while maintaining product quality.

This machine has been a huge upgrade for our production. The consistency and quality of the elastomer products are better than ever.

Giovanni Ricci ItalyGreat machine for elastomer production. It’s easy to maintain and produces excellent-quality products with minimal waste.

Victoria Zhang ChinaOur elastomer production has been revolutionized since we introduced this machine. It’s efficient, accurate, and cost-effective.

Kevin White AustraliaApplication Of UREXCEED PU Elastomer Casting Machine

UREXCEED polyurethane casting machine is an efficient equipment specially used to produce polyurethane elastomer products and is widely used in many industries. It is suitable for the production of various types of polyurethane elastomer products, including industrial rollers, seals, mold parts, anti-vibration pads, mining screens and wheel coatings, etc. Due to the excellent wear resistance, impact resistance, elasticity and chemical resistance of polyurethane elastomers, casting machines are widely in demand in fields such as transportation, mining, construction, petrochemical industry, and electronic and electrical industries.

PU Casting Machine For Suitcase Wheels

PU Casting Machine For Dumbbel

PU Casting Machine For Ceramic Tile

PU Casting Machine For Forklift Wheel

PU Casting Machine For Pipe Insulation

PU Casting Machine For Roller

PU Casting Machine For Scraper

PU Casting Machine For Screen

Certificate Of UREXCEED PU Casting Machine

UREXCEED PU Casting Machine meets the highest international quality and safety standards, ensuring optimal performance and reliability in production. The machine is certified under ISO 9001:2015, guaranteeing that it adheres to stringent quality management protocols throughout the design, production, and service stages. Additionally, it holds CE certification, signifying compliance with European safety and environmental regulations, and RoHS certification, ensuring it meets industry standards for materials and components. UREXCEED also provide comprehensive documentation, including material certifications, inspection reports, and traceability records, offering customers full transparency and confidence in the machine’s quality and regulatory compliance. These certifications reflect our commitment to delivering high-quality, reliable equipment that meets global industry standards.

We are extremely pleased with the performance of the elastomer machine. It delivers excellent results every time.

John Adams USA