PU Gasket Dispensing Machine

- Strict Quality Control System

- Strong Production Capacity

- Diversified Product Line

- Customized Solutions

PU Gasket Dispensing Machine

UREXCEED gasket dispensing machine is a high-efficiency and precision equipment designed specifically for the production of cabinet door gaskets. Using advanced high-pressure injection technology, this machine precisely controls the flow and temperature of the liquid materials, ensuring uniform dispensing and excellent sealing performance of the gaskets. Typically equipped with multiple dispensing heads, the gasket dispensing machine can simultaneously inject various materials to meet different hardness and elasticity requirements. With a high degree of automation and user-friendly operation, this machine significantly improves production efficiency, reduces labor costs, and ensures consistent product quality. Additionally, UREXCEED machine features an advanced monitoring system to track the production process in real-time, ensuring precise control over each manufacturing stage. Widely used in industries such as home appliances, automotive, and construction, the PU gasket machine is an essential tool for producing high-quality sealing gaskets.

| Travel Range (X/Y/Z) | 2250×1250×200mm (customizable) |

| Dimensions | 2500×2200×2200mm (customizable) |

| Weight | 1600kg |

| Total Power | 3-4kW |

| Gasket Width | 5-30mm (adjustable within the range) |

| Mixing Ratio | 1:1-10:1 |

| Application Rate | 0.3-5 g/s |

| Travel Speed | 0-30 m/min |

| Working Temperature | -15°C to 35°C |

| Metering Accuracy | ±0.005 |

Want to know more about specification of gasket dispensing machine?

UREXCEED PU Gasket Dispensing Mahcine

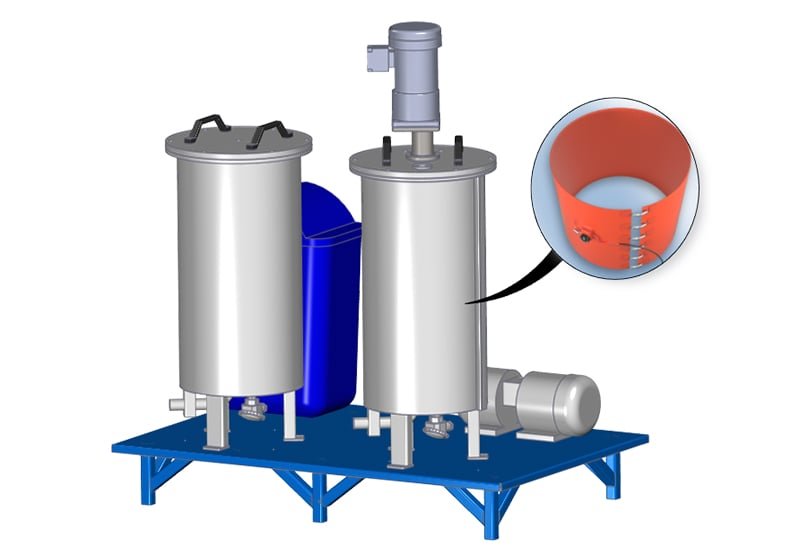

Water-cooled Storage Tank

The water-cooled storage tank is designed with a double-layer structure made of 316 stainless steel for enhanced durability and hygiene. It incorporates an automatic stirring system to ensure consistent material quality, along with advanced gas content monitoring and automatic air compensation to maintain optimal processing conditions. The tank also features an integrated underload alarm to stabilize material levels, and supports automated foam gasket filling for uninterrupted production. Its high-efficiency temperature control system eliminates the need for external air conditioning, simplifying installation and saving valuable space.

UREXCEED PU Gasket Dispensing Mahcine

Concrol System

Supports remote operation through network connectivity, enabling real-time audio and video communication as well as virtual troubleshooting for efficient technical support.

Equipped with intelligent simulation capabilities to eliminate errors caused by manual measurement, ensuring high-precision operation.

Features fully automated image generation—2D product designs require no programming, and 3D products can be created without relying on CAD blueprints—thanks to advanced robotic control.

Provides flexible and precise control over foam gasket shapes in diverse application scenarios, ensuring adaptability and consistent performance.

UREXCEED PU Gasket Dispensing Mahcine

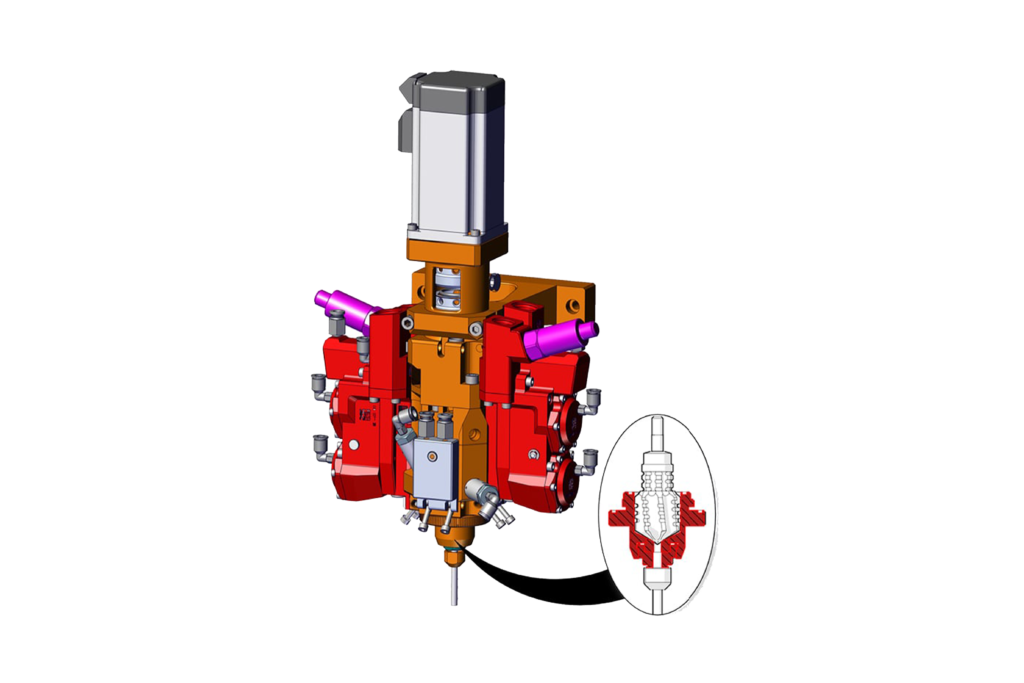

Precise Material Mixing System

The material dispensing system is engineered for high-precision ratio control, ensuring accurate mixing of multiple components. This minimizes material waste while maintaining consistent product quality. Through automatic adjustment of individual material volumes, the system ensures that each foam gasket meets the required specifications for hardness, elasticity, and overall performance.

UREXCEED PU Gasket Dispensing Mahcine

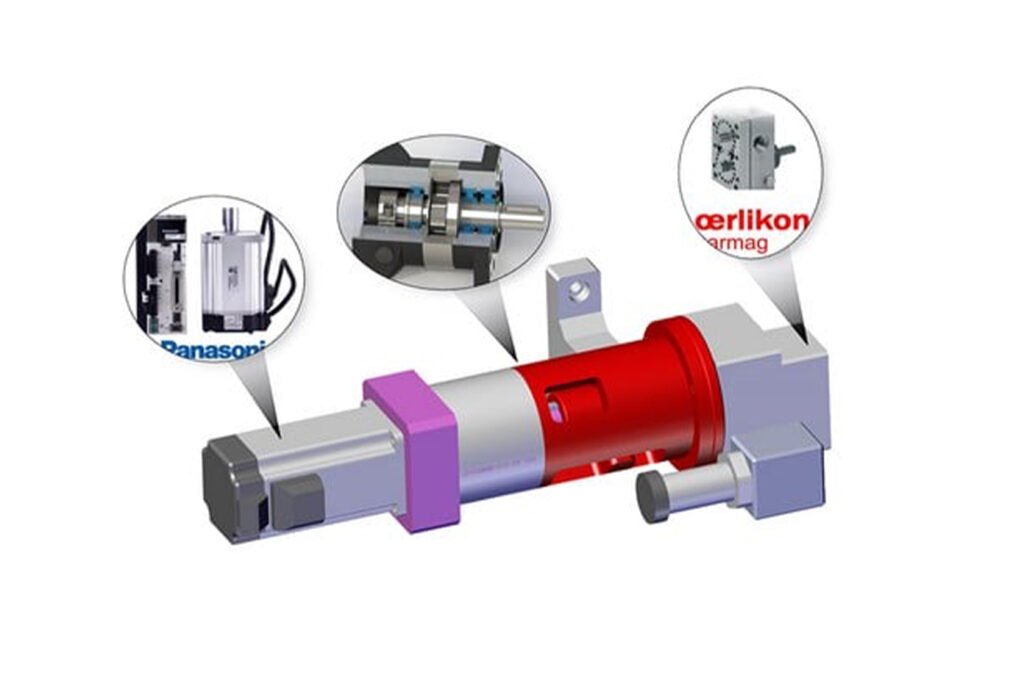

Metering Pump

The gear metering pump, sourced from renowned German manufacturer Barmag, delivers high-precision dispensing with a metering accuracy of ±2%, ensuring consistent and accurate material application. Its adjustable flow rate provides flexibility to accommodate varying production requirements, while its robust construction guarantees long-term reliability with minimal maintenance. The pump operates smoothly, helping to reduce material waste and enhance overall production efficiency.

Working Principle Of UREXCEED PU Gasket Machine

UREXCEED polyurethane gasket machine is a specialized piece of equipment designed for producing polyurethane gaskets, widely used in industries such as furniture and appliances. These gaskets ensure the cabinet doors are sealed, soundproof, and water-resistant. The working principle of the machine is as follows:

01 Raw Material Supply

The machine typically uses two primary raw materials: polyether polyol and isocyanate. These materials are stored in separate tanks and are delivered to the mixing head through a precision metering pump system.

02 Material Mixing

The mixing head combines the polyether polyol and isocyanate at an exact ratio using a high-precision metering device. During the mixing process, high-shear technology ensures the materials are evenly blended, preventing uneven reactions and ensuring consistent product quality.

03 Injection Molding

The mixed materials are injected into a mold through the machine’s injection system. The mold determines the shape and dimensions of the gasket. The machine is typically equipped with a heating system to maintain the material’s viscosity during the injection process, allowing for smooth and efficient filling of the mold.

04 Curing and Post-ProcessingCuring and Cooling

After injection, the polyurethane materials undergo a chemical reaction and begin to cure within the mold, forming the gasket’s final shape. Once the curing process is complete, the gasket enters the cooling system (e.g., water cooling or air cooling) to ensure it is fully hardened and stabilized.

FAQs Of UERXCEED PU Gasket Dispensing Machine

The pouring machine injects liquid polyurethane raw material directly into the mold to form a sealing strip, while the extruder extrudes the polyurethane material into shape through heat and pressure. The pu gasket dispensing machine is more suitable for the production of sealing strips with complex shapes and high precision requirements.

This equipment accurately controls the proportions of components A and B, injects two liquid polyurethane materials into the mold, and foams and hardens through a chemical reaction to form a high-quality sealing strip.

Production efficiency depends on equipment configuration and production requirements. Generally speaking, each pouring time is shorter, which can achieve high-efficiency production and is especially suitable for mass production.

The equipment requires regular inspection and cleaning of the nozzle, mold and liquid supply system. It is also necessary to regularly replace seals, filters and other wearing parts to ensure the stable operation of the equipment.

Hardness and density are mainly controlled by adjusting the ratio of components A and B. The equipment is usually equipped with a precise proportional control system to ensure that the sealing strips produced every time meet the requirements.

If properly maintained, the service life of a pu gasket dispensing machine is typically 8-10 years. Regular inspections and keeping them in good working order can extend the life of your equipment.

Yes, equipment can be customized based on customer needs, such as changing mold configurations, adding automation features, or adjusting production capacity to meet specific production requirements.

The energy consumption of polyurethane gasket dispensing machines is generally low because the equipment reduces energy waste through efficient control systems and precise material proportions.

Modern polyurethane gasket dispensing machines can use environmentally friendly polyurethane raw materials (such as low-GWP foaming agents), comply with environmental standards, and reduce the impact on the environment.

The operation of the pu gasket dispensing machine is relatively simple. Most equipment is equipped with an automated control system, and the operator only needs to simply set parameters to start production.

Production efficiency can be improved by optimizing the production process, reducing mold change time, and improving automation. In addition, regular maintenance and adjustment of the working status of equipment are also key to improving efficiency.

If you are interested in our pu gasket machine,

please contact us immediately

Application Of UREXCEED PU Gasket Dispensing Machine

UREXCEED pu gasket dispensing machine is a high-precision equipment specially designed for the production of polyurethane sealant It is widely used in the manufacturing fields of home appliances, furniture and industrial equipment. pu sealant have excellent elasticity, aging resistance and temperature resistance, and can provide a long-lasting sealing effect. They are widely used in refrigerators, freezers, ovens, electrical control cabinets and other equipment.

PU Gasket Dispensing Mahcine For Automotive

To address these challenges, automotive manufacturers are incorporating automated foam in place gasket dispensing machines into their production lines. This innovative approach involves replacing traditional insert seals with durable polyurethane materials to provide a more effective and reliable solution to sealing problems, thereby increasing vehicle integrity, safety and longevity.

PU Gasket Dispensing Mahcine For Lighting

PU Gasket Dispensing Mahcine For Electrical Enclosure

PU Gasket Dispensing Mahcine For Filter Housing

PU Gasket Dispensing Mahcine For Plastic Enclosure

PU Gasket Dispensing Mahcine For Cleanroom Door

Certificate Of UREXCEED PU Gasket Dispensing Machine

UREXCEED PU Gasket Dispensing Machine meets the highest industry standards for safety, quality, and performance. It is certified under ISO 9001:2015 for quality management, ensuring that every stage of design, manufacturing, and service adheres to stringent quality control practices. The machine also holds CE certification, confirming compliance with European health, safety, and environmental regulations. Additionally, it is RoHS certified, ensuring that it meets standards for the use of non-hazardous materials in electronic and electrical components. UREXCEED provide complete documentation, including material certifications, inspection reports, and traceability records, guaranteeing transparency and confidence in the machine’s performance. These certifications demonstrate our commitment to delivering high-quality, reliable equipment that meets global industry standards and regulatory requirements.