Foam Ear Plugs Production Line

UREXCEED earplug production line is designed for efficient and automated production of high-quality polyurethane earplugs, which are widely used in medical, industrial, personal protection and other fields.

Advantages Of Ear Plugs Production Line

1)Standardized production:

- The production line can realize standardized production process and ensure stable and reliable product quality.

- The professional equipment and operating procedures of each process improve production efficiency and consistency.

2)Scale benefits:

- The production line can realize large-scale and continuous production and give full play to scale benefits

- Reduce the manufacturing cost of unit products and improve overall profitability.

3)Flexibility and responsiveness:

- The production line can quickly adjust product types and output according to market demand

- It can meet customers personalized needs in a timely manner and improve customer service levels

4)High degree of automation:

- The production line adopts a large number of automated equipment and intelligent control systems.

- Reduces manual operation and improves production efficiency and consistency.

5)Safety and health protection:

- The production line is equipped with professional safety protection facilities to ensure a safe working environment.

- Cleanliness control during the production process ensures the sanitary quality of the product

About UREXCEED Production Line

UREXCEED offers two primary production line layouts to meet diverse manufacturing needs: Straight Line Layout and Rotary Line Layout.No matter the complexity or scale of your production needs, UREXCEED have the right line for you, ensuring maximum productivity and minimal downtime. Our comprehensive solutions are designed to improve efficiency, reduce operational costs, and enhance the overall manufacturing process.

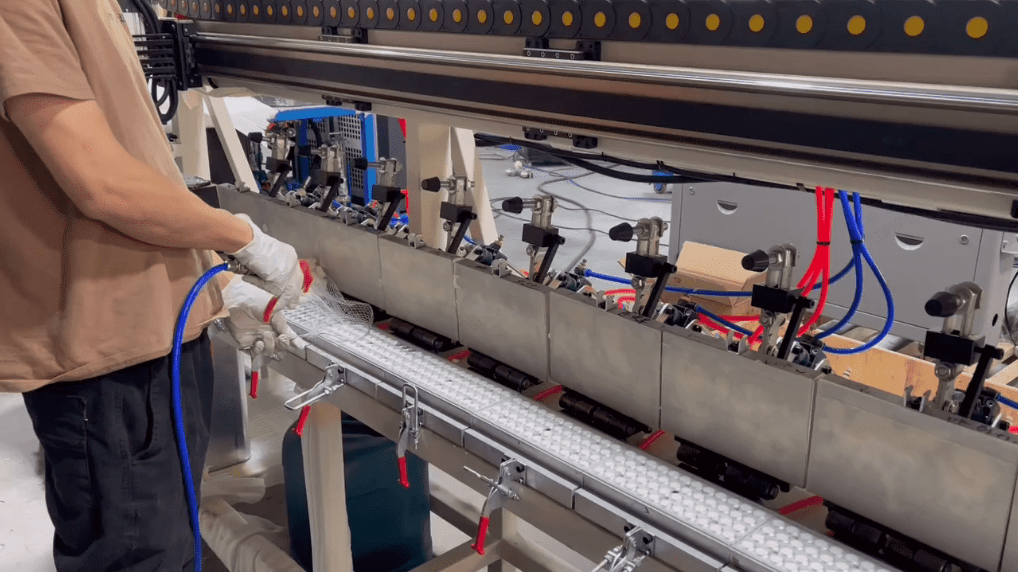

Straight Line Layout

Best for simple products with few processing steps.

Features:

High Space Utilization: Ideal for facilities with limited space, effectively utilizing floor area.

Ease of Operation: The linear arrangement allows operators to easily monitor and maintain equipment.

Suitable for Automated Production: Perfect for high-automation lines, reducing manual intervention and enhancing production efficiency.

Suitable Scenarios:

Short-Distance Production: Best for simple products with few processing steps. High-Automation Production Lines: Ideal for environments requiring high levels of automation.

Rotary Line Layout

Ideal for processes like assembly and coating.

Features:

Space Efficiency: Circular design allows for multi-step production within a compact area.

Suitable for Multi-Step Production: Ideal for processes involving multiple stages, effectively organizing production flow.

Enhanced Production Efficiency: Strategic arrangement of steps reduces material handling time, boosting overall efficiency.

Suitable Scenarios:

Multi-Step Production: Ideal for processes like assembly and coating.

Production Lines with Significant Manual Intervention: Suitable for environments where manual operations are prevalent.

Production Process Of UREXCEED Earplug Production Line

UREXCEED foam ear plug production line utilizes advanced technology and automated equipment to efficiently and consistently manufacture high-quality polyurethane ear plugs. The process encompasses several key stages, including raw material preparation, mixing, foaming, molding, cooling, trimming, quality inspection, and packaging. Each step is meticulously designed to ensure that every ear plug meets stringent quality standards. The high degree of automation in our production line reduces manual intervention, lowers production costs, and enhances overall efficiency, providing our clients with reliable and cost-effective manufacturing solutions.

For a visual overview of the ear plug production process, you might find the following video informative:

Spraying Release Agent

Injection of raw materials then put a silicon cover pad on the top instead of mold release agent

Lock the mold then take out the products

bake the earplug to get rid of water(for aqueous system only)

One-stop Solution Of PU Earplug Production Line

UREXCEED provide one-stop services for earplug production, covering the entire process from raw material procurement, production line design and manufacturing to mold development. Our services are designed to simplify your production process and ensure high quality and efficiency. By integrating all links, we are able to optimize costs, shorten time to market, and reduce communication costs. Our team of experts will be involved throughout the process to ensure that every detail meets your requirements, saving you the trouble of running between multiple suppliers. This one-stop solution not only improves production efficiency, but also enhances quality control, ultimately achieving higher customer satisfaction.

Foam Machine

Mold

Raw Material

Contact us to get a solution

30% cheaper than European production lines

FAQ Of PU Earplug Production Line

A polyurethane earplug production line typically requires polyurethane raw materials, hardeners, catalysts, foaming agents, etc. The specific raw materials depend on the earplugs’ required performance (such as hardness, density, elasticity, etc.).

Ensuring earplug quality relies on controlling the temperature, pressure, and mixing ratio during the foaming process. High-quality raw materials, a stable production environment, and precise machine control are fundamental to ensuring quality.

The production speed of a polyurethane earplug production line depends on the machine configuration and production process. Typically, multiple earplugs can be produced per minute, and the speed can be adjusted according to demand.

Maintenance of the polyurethane earplug production line is relatively simple but requires regular cleaning of the foaming machines and molds, as well as checking the hydraulic, electrical, and transmission systems. Periodic replacement of wear parts, such as seals and filters, can help reduce the occurrence of faults.

Modern polyurethane earplug production lines can achieve high levels of automation, including automatic material feeding, mixing, foaming, mold filling, demolding, and cutting. Some advanced lines are also equipped with automatic inspection systems to ensure quality at every stage of the production process.

The production cycle is generally short, usually between a few minutes and around ten minutes, depending on the earplug’s thickness, hardness, and the configuration of the production line.

Waste material from the production process can be processed through a recycling system and reused in foaming. Some waste materials can also be compressed and degassed for reuse, reducing resource waste.

Modern polyurethane earplug production lines are highly flexible, allowing for the adaptation to different sizes, shapes, and hardness of earplugs by changing molds and adjusting production parameters.

To ensure environmental compliance, production lines need to meet relevant environmental protection standards, using low-pollution and low-emission production processes. Some lines are equipped with exhaust purification devices and wastewater treatment systems to minimize environmental impact.

Bubbling issues are usually caused by inaccurate raw material ratios, uneven mixing, excessive temperature, or unsuitable foaming agents. Ensuring accurate ratios and mixing, controlling the foaming temperature, and selecting the right foaming agents are key to solving bubbling problems.

Good Review Of UREXCEED Foam Machine

Our earplug production line has been highly praised by many customers, who generally believe that it has excellent performance and is easy to operate. Many users said that the automated design of the production line has significantly improved production efficiency and can quickly and stably produce high-quality earplugs. Customers especially appreciate the one-stop service we provide, from raw materials to mold design, to installation and commissioning of the production line, all links are handled by a professional team to ensure the smooth progress of the project.

The one-stop service provided by this company is unmatched. From high-quality materials to custom molds, everything we need is handled seamlessly. Our production efficiency has greatly improved!

Carlos Fernandez SpainWe’ve recently switched to their production line for our foam products, and the results are outstanding. The quality is consistent, and the production rate has increased. Their team is very professional.

Maria Garcia MexicoWe’ve recently switched to their production line for our foam products, and the results are outstanding. The quality is consistent, and the production rate has increased. Their team is very professional.

Ahmed Al-Farsi UAEWe’ve been using their polyurethane equipment for several months, and it has greatly enhanced our production capacity. The customer service has been fantastic in providing ongoing support and advice.

Tariq Khan Pakistan

We’ve been using their foam ear plug production line for over a year now, and it’s been a game-changer for our production speed and efficiency. The setup was quick, and the team provided excellent support. Highly recommended!

John Smith USA