Polyurethane high-pressure machines represent a significant investment for manufacturing businesses, with prices typically ranging from $30,000 to $200,000 depending on various factors including capacity, features, and brand reputation. The cost variability reflects not just the machine's raw specifications but also its technological sophistication, manufacturing precision, and long-term operational efficiency that directly impacts a business's production capabilities.

Key Takeaways

- Entry-level polyurethane high-pressure machines start around $30,000 to $50,000 with limited capacity and features

- Mid-range industrial models cost between $50,000 to $100,000 offering better reliability and output

- High-end systems with advanced features and premium components range from $100,000 to $200,000

- Ongoing maintenance costs add approximately 15-20% of the purchase price annually to the total ownership expense

- Additional costs include installation ($5,000-$15,000), training ($2,000-$5,000), and customization fees

Understanding Polyurethane High-Pressure Machines

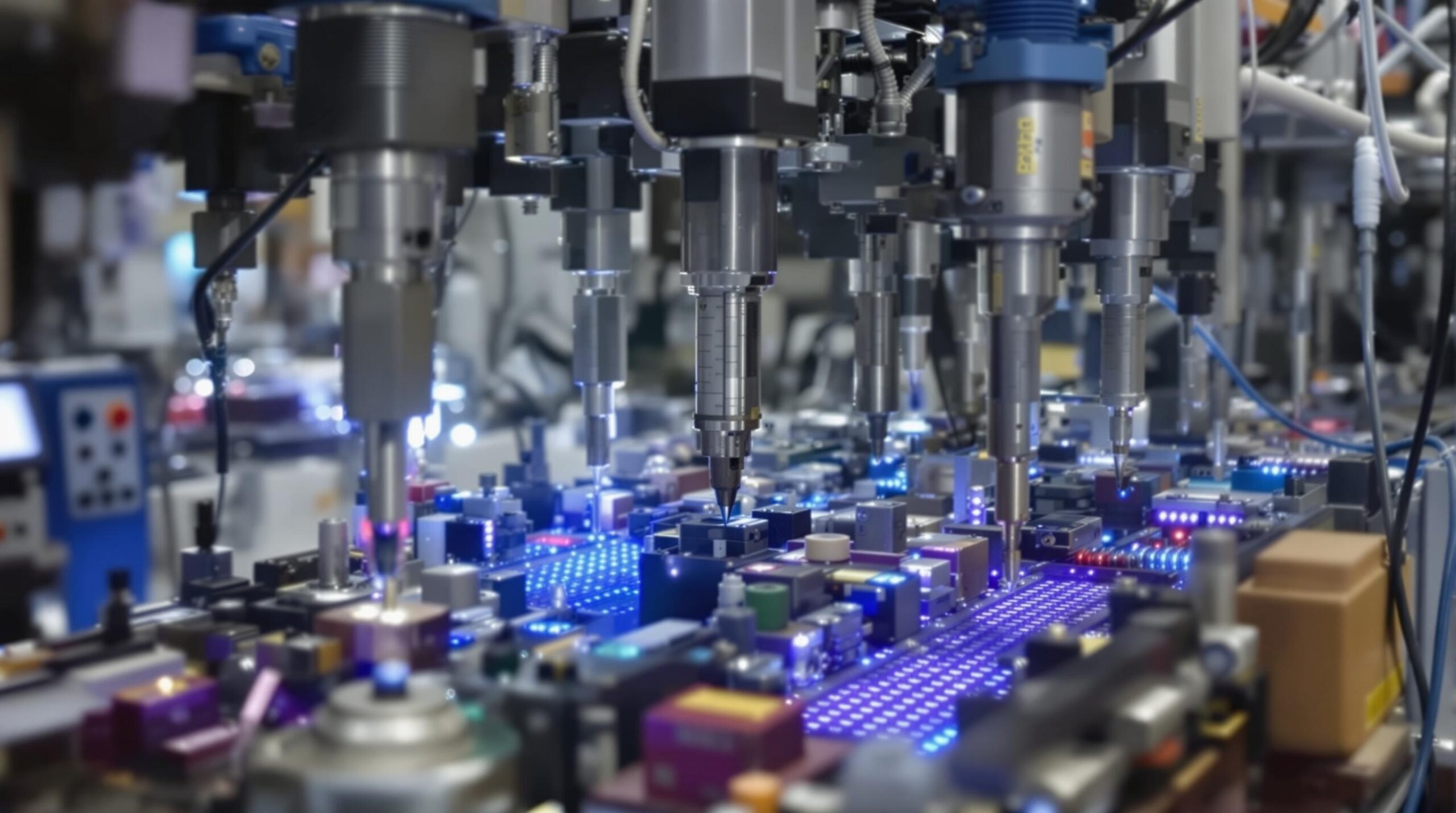

Polyurethane high-pressure machines are specialized industrial equipment designed to mix and dispense polyurethane components under high pressure. These machines combine isocyanates (A-component) and polyols (B-component) to create polyurethane foam or elastomers used in various manufacturing applications. The high-pressure technology ensures precise mixing ratios and consistent product quality.

The core function of these machines involves heating components to optimal processing temperatures, maintaining them at specific pressures (typically 1500-3000 psi), and then combining them in an impingement mixing chamber. This process creates chemical reactions resulting in foam expansion or elastomer formation, depending on the formulation used.

These machines serve numerous industries including automotive manufacturing, furniture production, construction materials, insulation, and refrigeration. The versatility and precision of high-pressure polyurethane equipment make it essential for operations requiring consistent, high-quality PU applications.

Entry-Level High-Pressure Polyurethane Machines

Entry-level high-pressure polyurethane machines typically cost between $30,000 and $50,000. These machines provide basic functionality suitable for small to medium production operations or businesses just entering the polyurethane manufacturing sector.

At this price point, you can expect machines with output capacities of 10-20 pounds per minute and somewhat limited customization options. These entry-level models generally feature:

- Basic control systems with manual adjustments

- Smaller material tanks (typically 30-60 gallons)

- Standard mixing heads with limited configuration options

- Basic heating systems with reasonable temperature control

- Limited automated features

While these machines provide adequate performance for basic operations, they may lack the advanced technology and durability found in more expensive models. Many small manufacturers find these machines suitable for initial production needs, though they often require upgrades as production scales.

Mid-Range Industrial High-Pressure Polyurethane Machines

The mid-range category of polyurethane high-pressure machines falls between $50,000 and $100,000. This price bracket represents the most common purchase point for established manufacturing operations seeking reliable, daily production equipment.

Machines in this category offer considerably improved features compared to entry-level options, including:

- Output capacities of 20-40 pounds per minute

- Digital control systems with programmable parameters

- Larger material tanks (60-120 gallons)

- Multiple mixing head options

- Advanced heating and pressure regulation systems

- Partial automation capabilities

The reliability improvements in this category represent significant value for businesses with regular production schedules. These machines typically feature better component quality, more precise controls, and improved durability, resulting in fewer breakdowns and maintenance issues.

Many mid-range machines also offer enhanced safety features and easier operation, reducing training requirements and improving operator efficiency. For most small to medium manufacturing operations, this category provides the optimal balance between cost and capabilities.

High-End Premium Polyurethane High-Pressure Systems

Premium polyurethane high-pressure machines start around $100,000 and can exceed $200,000 for the most advanced systems. These top-tier machines represent significant investments but deliver exceptional performance, reliability, and advanced capabilities.

At this price level, manufacturers can expect machines featuring:

- High output capacities exceeding 40-100 pounds per minute

- Full computerized controls with touchscreen interfaces

- Precision ratio control with real-time adjustments

- Multiple specialized mixing head options

- Extensive automation capabilities

- Remote monitoring and diagnostics

- Advanced data tracking and production analytics

Premium machines incorporate superior components throughout, including higher-grade pumps, heaters, and hydraulic systems that significantly extend operational life. These machines often feature modular designs allowing for easier maintenance and future upgrades.

Large-scale operations with high-volume requirements or those producing specialized polyurethane products with strict quality requirements find these machines justify their higher cost through improved output consistency, reduced waste, and lower long-term operational costs.

Factors Affecting Machine Pricing

Several key factors influence the final price of a polyurethane high-pressure machine beyond basic model categories. Understanding these price determinants helps in making more accurate budget estimates.

Output capacity significantly impacts machine cost, with higher capacity machines (measured in pounds per minute) commanding premium prices. Each additional pound of output capacity can add thousands of dollars to the machine's price, especially at the higher end of the spectrum.

The type and number of mixing heads included also substantially affect pricing. Basic single mixing heads may add $5,000-$10,000, while specialized or multi-component heads can add $20,000 or more to the total cost. Multiple mixing head configurations for different applications further increase prices.

Control system sophistication ranges from basic manual controls to fully computerized systems with advanced programming capabilities, each level representing a price increase. The difference between basic and advanced control systems can amount to $15,000-$30,000.

Other significant pricing factors include:

- Material tank capacities and heating systems

- Pump types and quality (piston vs. gear pumps)

- Hydraulic system specifications

- Automation level and integration capabilities

- Safety features and compliance certifications

- Brand reputation and support infrastructure

Geographic location also impacts pricing through import duties, taxes, and regional pricing strategies. Machines manufactured in Europe or North America typically command higher prices than those from emerging markets, often reflecting perceived quality differences.

Additional Costs Beyond Purchase Price

The base price of a polyurethane high-pressure machine represents only part of the total investment required. Several supplementary costs should be factored into budget planning.

Installation fees typically range from $5,000 to $15,000 depending on machine complexity and facility requirements. This often includes:

- Electrical connections and potential facility upgrades

- Compressed air and hydraulic system connections

- Machine positioning and securing

- Initial calibration and testing

Operator training costs between $2,000 and $5,000 for basic instruction, with advanced technical training potentially doubling this amount. Many manufacturers include basic training with purchase but charge for extended or specialized training programs.

Customization requests significantly impact final pricing. Common customizations include:

- Special mixing head configurations ($5,000-$25,000)

- Custom control system programming ($3,000-$10,000)

- Integration with existing production lines ($10,000-$30,000)

- Specialized material handling systems ($15,000-$50,000)

Shipping and logistics can add substantial expenses, particularly for international purchases. These costs typically range from $2,000 for domestic shipping to $15,000 or more for overseas transport, including customs clearance and special handling.

Maintenance and Operational Costs

Ongoing maintenance represents a significant component of the total cost of ownership for polyurethane high-pressure machines. Annual maintenance expenses typically range from 15-20% of the initial purchase price, varying based on usage intensity and environmental conditions.

Regular maintenance requirements include:

- Pump service and rebuilds ($2,000-$5,000 annually)

- Mixing head cleaning and maintenance ($1,500-$3,000 annually)

- Hydraulic system service ($1,000-$2,500 annually)

- Heating element replacement ($800-$2,000 as needed)

- Control system updates and calibration ($500-$2,000 annually)

Spare parts inventory represents another ongoing cost, with critical components like pump packings, seals, and mixing head components requiring regular replacement. A typical operation might spend $5,000-$15,000 annually on replacement parts depending on machine usage and age.

Operational costs include energy consumption, which varies significantly based on machine size and utilization. Most industrial high-pressure machines require 30-100 kW of power during operation, translating to $10,000-$30,000 in annual electricity costs for full-time operation.

Cleaning solvents and maintenance chemicals add $2,000-$5,000 annually to operational costs. Preventative maintenance service contracts, while optional, typically cost 10-15% of the machine purchase price annually but can reduce unexpected downtime and extend equipment life.

New vs. Used Machine Pricing

The used polyurethane high-pressure machine market offers potential savings but comes with important considerations. Used machines typically sell for 40-70% of new prices, with the exact discount depending on age, condition, and technology level.

A machine that costs $100,000 new might sell for $40,000-$70,000 in the used market depending on:

- Age (machines lose approximately 10-15% value annually)

- Operational hours and production history

- Maintenance records and component condition

- Technology relevance compared to current standards

- Remaining useful life of critical components

When considering used equipment, factor in potential refurbishment costs which typically range from $10,000-$40,000 for thorough reconditioning. These costs often include pump rebuilds, control system updates, and mixing head reconditioning.

The availability of technical support and spare parts for older models represents a critical consideration. Machines over 10-15 years old may face parts obsolescence issues, potentially leading to extended downtime and costly custom fabrication of replacement components.

Used equipment warranties, if available, typically cover only 30-90 days compared to the 1-2 year warranties standard with new equipment. Some dealers offer extended warranties on reconditioned equipment at additional cost, usually 5-10% of the purchase price.

Financing and Return on Investment

Most businesses utilize financing options when purchasing polyurethane high-pressure machines due to their significant capital requirements. Common financing approaches include equipment loans, leasing arrangements, and manufacturer financing programs.

Equipment loans typically require 10-20% down payment with terms ranging from 3-7 years. Interest rates vary based on business credit profiles but generally range from 4-10% depending on economic conditions and lender policies.

Leasing options include:

- Operating leases (lower monthly payments but equipment returns to lessor)

- Finance leases (higher payments but includes purchase option)

- Sale-leaseback arrangements (for businesses with existing equipment)

Return on investment calculations should consider production efficiencies gained from new equipment. Modern high-pressure machines typically offer 15-30% improved output compared to older technologies, potentially offsetting higher purchase prices through increased productivity.

Tax considerations also impact the total investment picture, with equipment purchases potentially qualifying for Section 179 deductions or bonus depreciation in the US market. These tax benefits can effectively reduce the net cost of new equipment by 25-40% depending on the business's tax situation.

Most manufacturers calculate breakeven points between 12-36 months for polyurethane equipment investments, with shorter periods for businesses replacing inefficient older equipment and longer periods for first-time purchases requiring new production processes.

Choosing the Right Machine for Your Budget

Selecting the appropriate polyurethane high-pressure machine requires balancing budget constraints with production requirements. First, determine your output capacity needs based on current and projected production volumes, as this represents the most fundamental sizing parameter.

Consider the complexity of your polyurethane applications. If you process multiple formulations or require frequent changeovers, investing in more sophisticated control systems and mixing head options may justify higher initial costs through reduced downtime and improved quality.

For businesses with budget constraints, consider these strategic approaches:

- Purchasing a higher-quality used machine rather than a new entry-level model

- Selecting machines with modular designs allowing future upgrades

- Focusing on core capabilities while deferring optional features

- Negotiating extended payment terms with manufacturers

- Exploring reconditioned equipment from reputable dealers

Evaluate the total cost of ownership rather than focusing exclusively on purchase price. A machine costing 20% more initially may offer lower operating costs through reduced material waste, energy efficiency, and maintenance requirements.

Request detailed quotes from multiple suppliers, ensuring each includes all necessary components, installation, training, and warranty coverage. This comprehensive approach prevents unexpected costs and enables meaningful comparisons between different machine options.

FAQs

What's the difference between high and low-pressure polyurethane machines?

High-pressure machines operate at 1500-3000 psi and provide superior mixing through impingement, producing higher quality foam with consistent cell structure. Low-pressure machines operate at 20-200 psi, use mechanical mixing, and generally cost $5,000-$30,000 - significantly less than high-pressure systems.

How long do polyurethane high-pressure machines typically last?

With proper maintenance, industrial-grade polyurethane high-pressure machines typically last 15-20 years. Critical components like pumps may require rebuilding every 3-5 years, while mixing heads need reconditioning annually depending on usage.

Can I upgrade my polyurethane machine rather than buying new?

Many polyurethane machines can be upgraded with newer control systems, improved mixing heads, or enhanced heating systems. Upgrade costs typically range from $15,000-$50,000 depending on scope, potentially extending machine life by 5-10 years at a fraction of replacement cost.

What production capacity can I expect at different price points?

Entry-level machines ($30,000-$50,000) typically process 10-20 pounds per minute. Mid-range machines ($50,000-$100,000) handle 20-40 pounds per minute. Premium machines ($100,000-$200,000) can process 40-100+ pounds per minute.

Are imported polyurethane machines less expensive than domestic ones?

Polyurethane machines from developing markets typically cost 30-50% less than European or North American equivalents. However, these savings may be offset by higher maintenance costs, parts availability issues, and sometimes shorter operational lifespans.