Air Filter Gasket Machine

- Strict Quality Control System

- Strong Production Capacity

- Diversified Product Line

- Customized Solutions

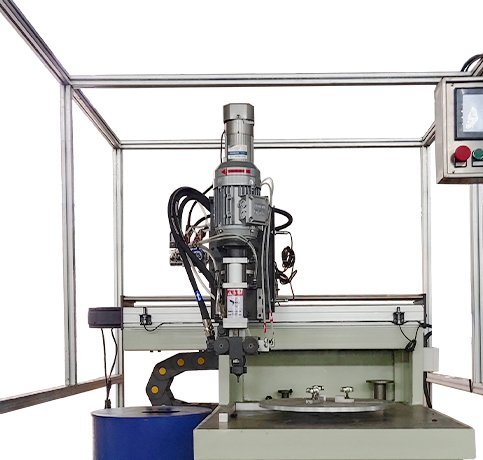

Air Filter Gasket Machine

UREXCEED air filters are widely used in the automotive industry with polyether low-density microporous elastomers as air filters and end caps. The urexceed filter gasket dispensing machine is simple to operate, easy to maintain, highly automated and has stable performance.

Want to know more about specification of air filter gasket machine?

Mixing Head

Material Tank

PLC

Working Principle Of UREXCEED Air Filter Gasket Machine

01 Material Delivery and Mixing

The raw materials are transported through pipelines to a mixing head. At the mixing head, the materials are mixed in precise proportions, and high-speed shear ensures uniform composition.

02 Casting Process

The mixed polyurethane material is injected into a mold, typically shaped like the air filter. The material fills the mold and begins to cure within the mold cavity.

03 Curing and Demolding

After the polyurethane material is injected into the mold, it undergoes a curing process. The time required for curing depends on the chemical properties of the materials and the temperature conditions. Once cured, the mold opens, and the finished air filter component is ejected.

04 Automation Control

Air filter gasket machines are typically equipped with an automated control system that precisely regulates factors like material ratios, temperature, and time to ensure product quality and production efficiency.

FAQs Of UREXCEED Air Filter Gasket Machine

Compared with traditional manual dispensing, the air filter gasket machine has a higher level of automation, which can improve production efficiency, ensure accurate material proportions, and reduce manual intervention. It can also achieve continuous production of multiple molds in a short time, suitable for mass production needs.

Yes, air filter casting machines are usually equipped with a flexible mold replacement system, which can adjust the size or shape of the mold according to the requirements of different specifications of filter elements to produce air filter products of various specifications. Some equipment supports customized molds.

The air filter gasket machine has high production efficiency and can usually complete a dispensing process in a short time. The equipment can continuously produce multiple filter elements, adapting to mass production and improving overall production efficiency.

The modern air filter gasket machine is equipped with an automated control system and a simple and intuitive operation interface. The operator only needs to set the parameters and start the equipment, and the machine will automatically complete the mixing, injection and foaming processes. Most equipment also has automatic cleaning functions, reducing manual operations.

Clean the mixing chamber, nozzles and pipes regularly to prevent polyurethane material residue and clogging. Check the hydraulic system, heating system, proportional control system and other important components to ensure the normal operation of the equipment. Regularly replace wearing parts such as seals, filters, etc. to extend the working life of the equipment.

Yes, the air filter gasket machine can be applied to different types of polyurethane raw materials, including flexible foam and rigid foam. By adjusting the equipment’s control system and foam material ratio, appropriate polyurethane raw materials can be selected according to product needs to meet different performance requirements.

The energy consumption of the air filter gasket machine is relatively low, especially with the help of modern energy-saving design and efficient control system, the energy consumption is effectively controlled. The energy efficiency of the equipment mainly depends on the production scale, heating requirements and foaming process.

Density and hardness can be controlled by adjusting the ratio of components A and B, foaming temperature and reaction time. Modern air filter gasket machines are usually equipped with precise proportion control and temperature control systems to ensure that the density and hardness of the filter element meet the requirements.

Cleaning the air filter gasket machine is relatively simple. The equipment is equipped with an automatic cleaning function, and usually only the mixing chamber, nozzles, pipes and other parts need to be cleaned regularly to maintain the efficient operation of the equipment. Proper cleaning procedures prevent polyurethane residue and clogging and ensure foaming results.

The service life of an air filter gasket machine is generally 8-10 years. The specific service life depends on the maintenance of the equipment, the frequency of use and the type of raw materials. Regular maintenance and timely replacement of wearing parts can effectively extend the service life of the equipment.

Yes, the air filter gasket machine can be used in conjunction with other equipment (such as automatic cutting machines, packaging equipment, testing equipment, etc.) to form a complete production line to meet mass production needs and improve overall production efficiency.

Production efficiency can be improved by optimizing the production process, reducing mold change time, and improving automation. In addition, regular equipment maintenance to keep the equipment in optimal operating condition is also the key to improving production efficiency.

Contact us for full range quote

UREXCEED machines are 30% cheaper than european machine

Why Choose UREXCEED Air Filter Gasket Machine

Good Review Of Air Filter Gasket Machine

UREXCEED Air Filter Gasket Machine has received exceptional feedback for its precision, efficiency, and reliability. Customers appreciate its ability to deliver consistent, high-quality gaskets for air filters, ensuring optimal performance and durability. Many users have highlighted how the machine significantly improves production speed while reducing material waste, making it an invaluable tool for manufacturers in the automotive and HVAC industries. Its easy operation and low maintenance requirements have been praised, with clients reporting minimal downtime and smooth integration into their existing production lines. Overall, the Air Filter Gasket Machine is highly regarded for its robust performance, making it a top choice for businesses looking to enhance their gasket production processes.

The air filter injection machine is easy to operate, and it delivers excellent results. We’ve seen improved filter performance and reduced defects.

Adrian Silva BrazilThe accuracy of the foam injection process has made a noticeable difference in the quality of our air filters. Highly recommend this machine!

Klaus Schneider GermanyOur production rate has increased, and our filters are more consistent in quality. The air filter injection machine is reliable and efficient.

Janet Parker UKThe air filter injection machine works well in high-demand environments. It helps ensure high-quality filtration for our products.

Yusuke Takahashi JapanCertificate Of UREXCEED Air Filter Gasket Machine

UREXCEED Air Filter Gasket Machine is certified with industry-leading quality standards, ensuring reliable performance and compliance with global manufacturing requirements. It is fully certified under ISO 9001:2015 for quality management, ISO 13485 for medical device manufacturing (where applicable), and IATF 16949:2016 for the automotive industry. These certifications guarantee that the machine meets the highest standards for precision, durability, and safety. Additionally, we provide comprehensive documentation, including material certification, batch traceability, and full inspection reports, giving customers confidence in both the machine’s quality and its consistent performance. Whether you’re in the automotive, HVAC, or filtration industries, our certified Air Filter Gasket Machine ensures top-tier manufacturing results and meets all relevant regulatory requirements.

Application Of UREXCEED Air Filter Gasket Machine

Related Products Of Air Filter Gasket Machine

In addition to our air filter gasket machine, we also offer a wide range of high-performance polyurethane equipment, including high-pressure foaming machines, low-pressure foaming machines, dispensing machines, spray machines, elastomer casting machines, and more. These machines are widely used across various industries to meet diverse customer production needs. If you’re interested in learning more about our other equipment, feel free to click to explore further. We are happy to provide detailed product information and technical support.

This machine has significantly improved the consistency and durability of our air filters. It’s an indispensable tool for our production.

Thomas Johnson Canada