High Quality Car Seat Production Line

Car Seat Production Line

UREXCEED polyurethane automotive seat production line is designed for efficient and high-precision molding of automotive seats, meeting the stringent requirements of modern automotive industries for comfort, safety, and environmental standards. The full production line includes a foaming machine, molds, and mold frames, integrated with advanced control systems to ensure the highest quality standards throughout the production process.

Process Flow Of UREXCEED PU Car Seat Production Line

Step1

Step2

Step3

Step4

Step5

About UREXCEED Car Seat Production Line

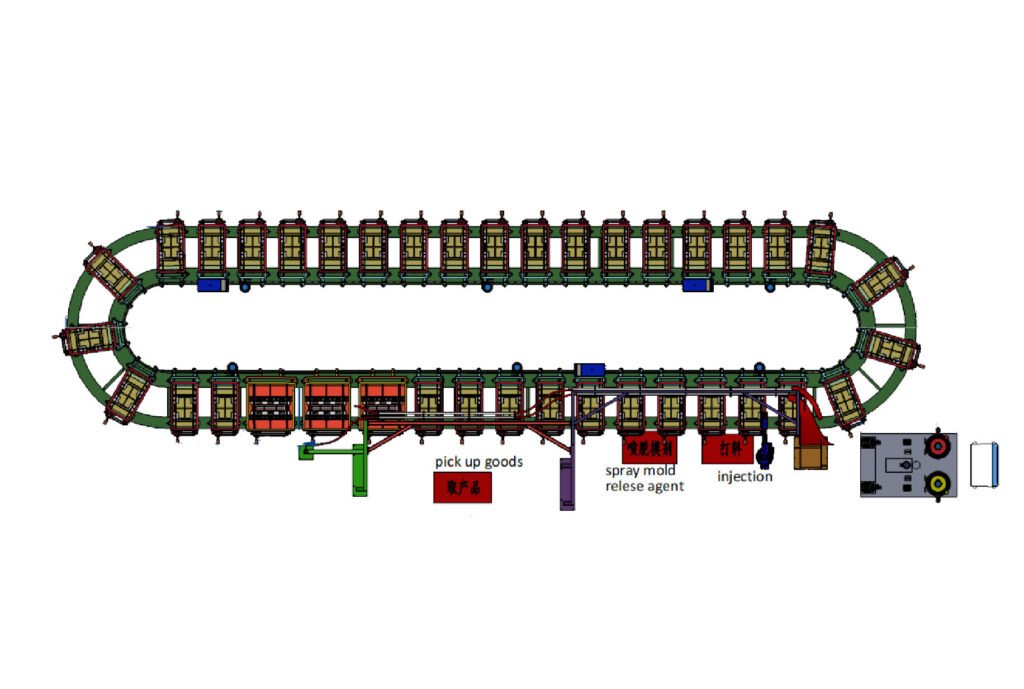

UREXCEED offers a wide range of customizable lines, including rotary lines, carousel lines and banana lines, designed to meet the specific needs of different manufacturing processes. Regardless of the complexity or scale of your production needs, UREXCEED can provide you with the right line to ensure maximum productivity and minimize downtime. Our comprehensive solutions are designed to increase efficiency, reduce operating costs and enhance the overall manufacturing process.

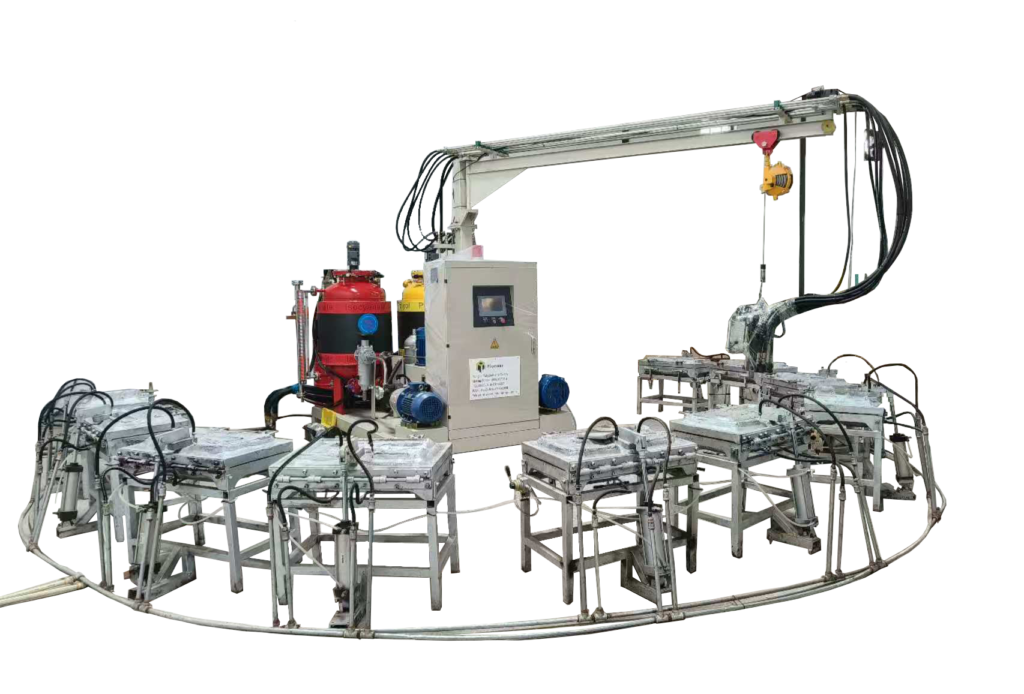

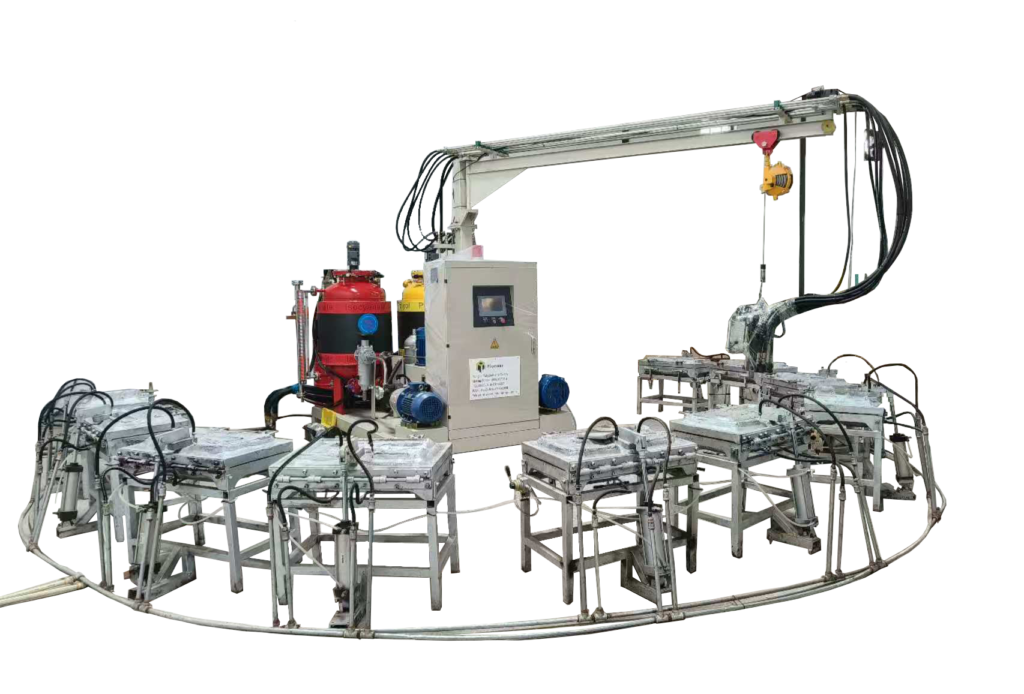

Carousel Production Line

Best for simple, short-cycle production with a straightforward structur

Applications:UREXCEED production line is suitable for relatively simple manufacturing processes, such as coating, pressing, or other operations. It is commonly used for small-batch production or products with specific process requirements.

Features: Compact and straightforward, the carousel production line is ideal for single-product manufacturing or small-scale, short-cycle production needs.

Rotary Production Line

Suitable for large-scale, multi-step automated production.

Applications: UREXCEED rotary production lines are often used for products requiring multiple processes and continuous production. They are especially effective in mass production and highly automated environments.

Features: With high flexibility, rotary production lines can be configured with multiple workstations. They are well-suited for long-term, high-efficiency production tasks, often involving more complex products.

Banana Production Line

Designed for products requiring specialized shapes or curved processing tracks, offering high flexibility.

Banana Production Line

Designed for products requiring specialized shapes or curved processing tracks, offering high flexibility.

Applications: This type of production line is used for processes requiring curved tracks or specific shapes. It is particularly suitable for handling flexible materials or manufacturing products with complex forms.

Features: Known for its adaptability, the banana production line can handle workpieces with unique shapes or angles, making it ideal for products needing variable-angle or shape-specific processing.

One- stop Solution Of Car Seat Production Line

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

Foam Machine

Mold

Mold Temperature Control Machine

Raw Material

Contact us for full range quote

UREXCEED machines are 30% cheaper than european machine

FAQs Of Car Seat Production Line

Uniform foaming is achieved by precisely controlling the raw material mix ratios, injection pressure, and mold temperature. The mold temperature controller plays a key role in maintaining consistent heat distribution, ensuring that the foam expands evenly and cures uniformly.

The mold temperature machine (or mold temperature controller) heats or cools the mold to maintain a constant temperature. This is critical for controlling the foaming reaction, ensuring proper material flow, and ultimately achieving a high-quality, consistent product.

Regular maintenance is essential. It includes:

- Routine inspections and cleaning of molds, nozzles, and mixing heads.

- Calibration of dosing pumps and monitoring of injection pressure.

- Preventive maintenance schedules to reduce downtime and maintain optimal production efficiency.

In case of issues, check the following:

- Raw Material Mix: Ensure the correct ratios of polyol and isocyanate.

- Injection Parameters: Verify that the injection pressure and speed are set correctly.

- Mold Temperature: Confirm that the mold is at the required temperature.

- Release Agent Application: Ensure even application to prevent sticking and surface defects.

Safety and environmental compliance are ensured by:

- Adhering to strict operational protocols and safety guidelines.

- Using eco-friendly raw materials and release agents.

- Implementing proper ventilation and waste management systems to control emissions and protect workers.

Operators receive comprehensive training that includes:

- Detailed operation manuals and on-site training sessions.

- Remote technical support and troubleshooting assistance.

- Continuous updates on best practices to ensure efficient and safe production.

Playlist

Transaction Case Of UREXCEED PU Car Seat Production Line

Good Review Of Car Seat Production Line

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

UREXCEED’s production line is reliable and efficient, boosting output and reducing downtime. We are very happy with the equipment and support.

Sarah Müller GermanyWe're very satisfied with UREXCEED's seat production line. It improved efficiency and ensured high quality. The team provided great technical support. Highly recommended!

Juan Pérez MexicoOur production efficiency increased by 30% with UREXCEED’s seat production line. The smart features reduced errors, and service was excellent. Very satisfied!

Abdul Aziz UAEUREXCEED’s production line is stable, efficient, and highly automated. It minimized errors and boosted production. Highly recommend!"

Carlos Mendoza SpainWe’ve seen great results with this spray foam machine. It delivers even coating and is easy to control.

The coating machine works seamlessly, applying just the right amount of glue every time. It's a great addition to our production line.

Eliot Davis Operations Director

A Mexican automotive parts manufacturer sought to improve seat production efficiency and ensure stable product quality. They required a highly efficient and automated polyurethane car seat production line, including a high-pressure polyurethane foaming machine, mold temperature controller, seat molds, and a production line. After multiple discussions, we provided a customized, energy-efficient solution, optimizing key processes such as mold heating, release agent spraying, material injection, and foaming. The client was impressed by our equipment stability, uniform foaming, and one-stop service, leading to a successful order. After installation, we offered remote technical support and on-site training to ensure smooth production. The line is now fully operational, delivering high product yield and helping the client enhance efficiency while reducing costs.

Mexico