Línea de producción de almohadas de espuma viscoelástica

UREXCEED polyurethane memory pillow production line is designed for efficient and precise manufacturing of memory foam pillows, making it the ideal choice to meet modern market demands. This production line features advanced Tecnología de espumación a alta presión, combinado con un diseño de molde preciso y sistemas de control automatizados, garantizando que cada almohada ofrezca un excelente rendimiento de memoria de forma y una comodidad superior.

Flujo de proceso de UREXCEED Pillow Production Line

PU Foam Pillow Product Process

Paso 1

Paso 2

Paso 3

Paso 4

Paso 5

Gel Pillow Product Process

Paso 1

Paso 2

Paso 3

Paso 4

Paso 5

Paso 6

Paso 7

Acerca de UREXCEED Línea de producción de almohadas de espuma

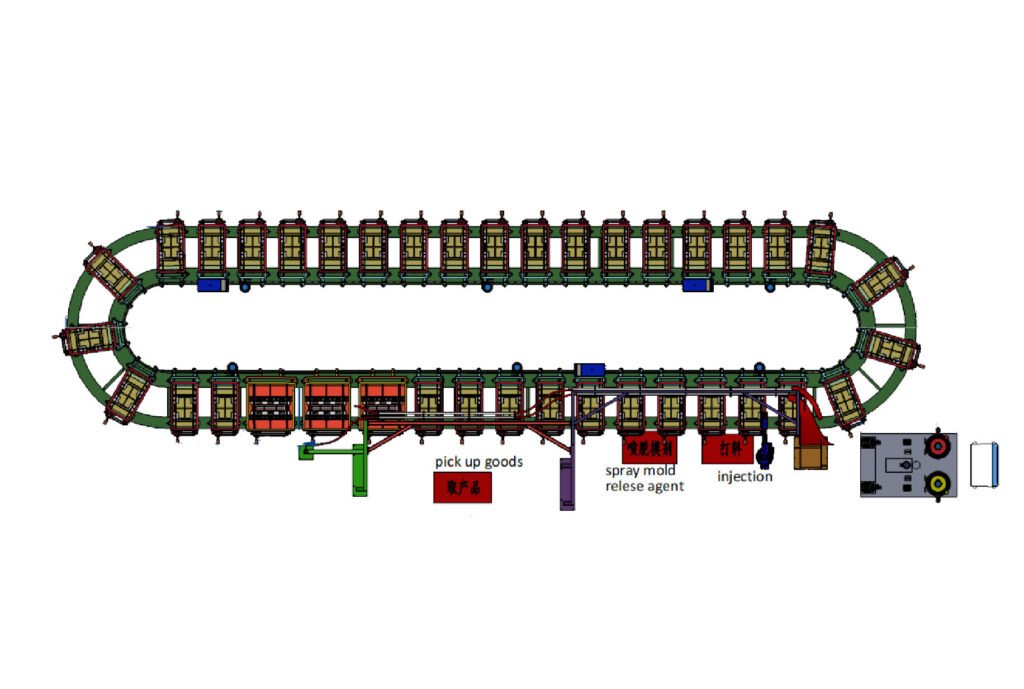

UREXCEED offer a variety of customizable production lines, including carousel lines, rotary lines, and banana lines, designed to meet the specific needs of different manufacturing processes. Each production line type is engineered for maximum efficiency, flexibility, and scalability, enabling businesses to optimize their production while maintaining high-quality standards.

No importa la complejidad o la escala de sus necesidades de producción, UREXCEED® Tenemos la línea adecuada para usted, garantizando máxima productividad y mínimo tiempo de inactividad. Nuestras soluciones integrales están diseñadas para mejorar la eficiencia, reducir los costos operativos y optimizar el proceso de fabricación en general.

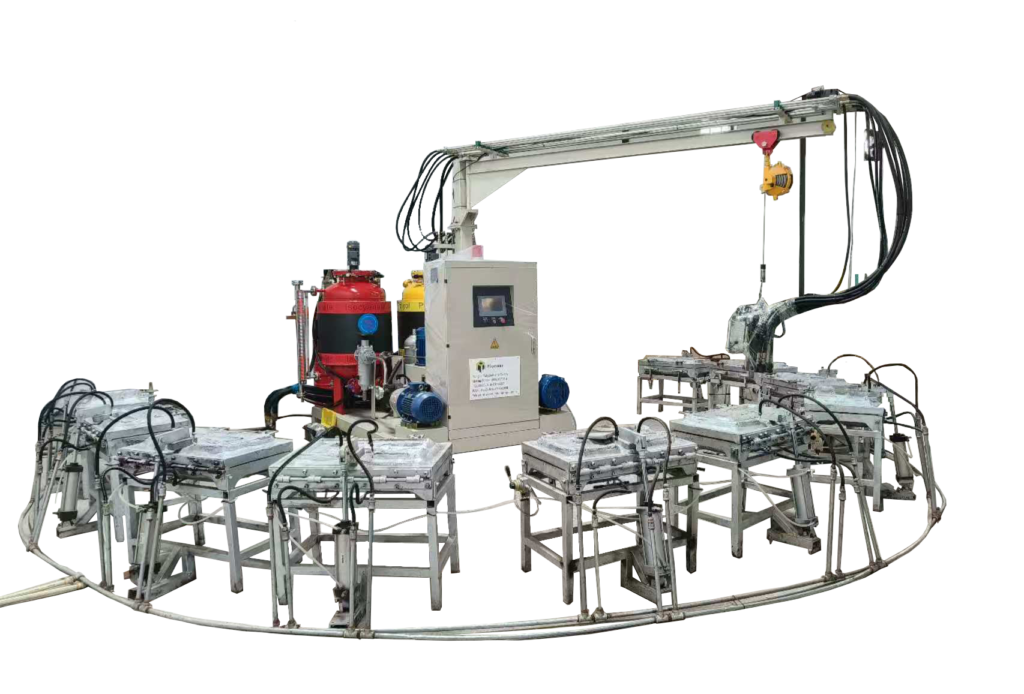

Línea de producción de carrusel

Adecuado para producciones de pequeña a mediana escala.

Operación: Compacto y adecuado para producciones de pequeña a mediana escala.

Ventajas:

·Diseño que ahorra espacio.

· Rentable para fábricas o gamas de productos más pequeñas.

·Fácil de mantener y operar.

Limitaciones:

·Escalabilidad limitada debido a su tamaño compacto.

·Menor capacidad de producción en comparación con sistemas de mayor tamaño.

Línea de producción rotativa

Ideal para producción continua de alta capacidad.

Operación: Operación automatizada o semiautomatizada con transiciones de molde suaves a lo largo de la pista.

Ventajas:

·Maximiza la utilización de la planta de producción con un diseño más flexible.

·Ideal para producción continua de alta capacidad.

·Admite moldes más grandes y pesados.

Limitaciones:

·Mayores costes de instalación y mantenimiento debido al sistema ferroviario.

·Requiere una planificación precisa durante la instalación de la fábrica.

Línea de producción de plátano

Se utiliza para procesos que requieren tiempos de enfriamiento prolongados.

Línea de producción de plátano

Se utiliza para procesos que requieren tiempos de enfriamiento prolongados.

Operación: Los moldes se mueven a lo largo de la trayectoria curva, lo que permite más tiempo durante etapas de producción específicas.

Ventajas:

·Ideal para productos que requieren tiempos de curado más largos, como almohadas más grandes o más densas.

·Reduce cuellos de botella en la producción al extender el tiempo en etapas críticas.

·Altamente personalizable para diseños de fábrica y procesos de producción.

Limitaciones:

·Requiere un espacio mayor en comparación con las líneas circulares y de disco.

·Ideal para procesos de producción especializados o de alta demanda.

Resumen de las diferencias

| Línea de montaje | Característica clave | Mejor para | Requerimientos de espacio | Capacidad de producción |

|---|---|---|---|---|

| Línea de producción de carrusel | Disco giratorio centralizado | Producción en pequeña escala | Bajo | Bajo |

| Línea de producción rotativa | Pista circular continua | Producción uniforme a gran escala | Medio | Alto |

| Línea rotativa de riel de tierra | Sistema de rieles empotrados en el piso | Moldes pesados, producción de alta capacidad | Medio-alto | Alto |

| Línea de producción de plátano | Pista curva extendida | Procesos largos de curado/enfriamiento | Alto | Medio-alto |

Recomendación:

- Líneas de disco o circulares:Adecuado para la producción de almohadas de espuma viscoelástica estándar con espacio y presupuesto moderados.

- Línea circular de riel terrestre:Ideal para fábricas que se centran en moldes de alta capacidad o pesados.

- Línea de plátano:Ideal para productos complejos que requieren tiempos de curado o enfriamiento prolongados.

Solución integral Línea de producción de almohadas de espuma de PU

UREXCEED foam pillow production line one-stop service is designed to provide customers with a comprehensive solution, from raw material sourcing to equipment installation and commissioning, as well as mold customization and production line setup. UREXCEED supply high-quality polyurethane raw materials, ensuring the comfort and durability of the pillows, and provide advanced foam pillow production equipment, including alta presión/máquinas de espumado de baja presión, automated assembly lines, and more, helping you improve production efficiency and reduce labor costs. Additionally, UREXCEED custom mold services allow for the production of molds in various sizes and styles to meet customer needs, ensuring product accuracy and consistency. Through this complete one-stop service, we help clients simplify the procurement process, reduce production risks, and enhance market competitiveness.

Sistema de materia prima

- Isocyanate (MDI): a key reaction component that affects the support and rebound properties of the foam.

- Polyether Polyol: Determines the softness and viscoelasticity of foam, and is the main material for regulating softness and hardness.

- Water: Reacts with isocyanates to produce CO ¾ gas, forming a pore structure and controlling the foaming rate.

- Catalyst: Adjust the foaming reaction rate, control the initiation time and molding efficiency.

- Crosslinking agent: enhances the stability of the foam structure, improves pressure resistance and durability.

- Emulsifiers/Surfactants: Optimize pore uniformity to prevent defects such as collapse and poor foaming.

- Auxiliaries (optional): antioxidants, anti-yellowing agents, flame retardants, fragrances, color pastes, antibacterial additives, etc., can be customized according to the target market

| Pillow type | Shore hardness (A) | Applicable population | Feature Description |

| Soft pillow | 10–15 | Women/children | Soft fit, low rebound |

| Medium soft (universal type) | 15–22 | Mass consumer market | Support + Comfort Balance |

| Rigid brace type | 22–30 | Cervical Support/Men’s Market | Obvious support, high rebound |

- The softness and hardness range of the pillow can be flexibly adjusted by the type and ratio of polyether (such as Shore hardness A 10-30).

- Can provide environmentally friendly, low VOC formulas, support REACH/CertificPUR certification requirements

- Customized fragrances, densities, and skin feel for different end point markets (cross-border e-commerce, high-end home furnishings, offline channels)

- A/B component storage tank (200L × 2)

- Precision heating constant temperature system (temperature control range 20-25 ℃)

- Mixing device (to prevent sedimentation)

- Pipeline pressurized circulating feeding system (connecting foaming equipment)

Maquina de espuma

| Project | High Pressure Foaming Machine | Low Pressure Foaming Machine |

| Working principle | Components A and B are mixed by high-pressure impact without mechanical stirring | Components A and B are mixed by mechanical agitation in the mixing head |

| Working pressure | 120–200 bar | Atmospheric or low pressure (< 10 bar) |

| Injection method | Mechanical arm automatic feeding/fixed-point feeding system | Manual injection/Simple guide rail injection |

| Mixing uniformity | Very high, fine and uniform pores | Generally, there may be slight color differences or hardness fluctuations |

| Cleaning method | High-pressure self-cleaning, usually without solvent | Manual cleaning, using organic solvents |

| Product consistency | Excellent, suitable for high-standard products | Generally, it is greatly affected by manual operation |

| Automated adaptability | Highly compatible with automated production lines | Suitable for manual operation, limited automation capability |

| Equipment costs | Higher (about 1.5-2 times that of a low-voltage machine) | Low, suitable for small and medium-sized initial investments |

| Raw material adaptation requirements | Higher temperature and viscosity control requirements for raw materials | Strong adaptability to raw material conditions |

| Applicable scenarios | High-end brands/export orders/high-quality foam | Start-up factories/small batch production/markets with low labor costs |

| Advantages summary | Good mixing effect, no installation, easy to clean, high efficiency | Low cost, simple structure, easy maintenance |

| Summary of shortcomings | High investment costs and strict requirements for raw material conditions | Cleaning is cumbersome, and product consistency is slightly poor |

| Indicator | High pressure pu foam machine | Low pressure pu foam machine |

| Mixed mode | High speed impact | Mechanical stirring |

| Mixing uniformity | ★★★★★ | ★★★☆☆ |

| Cost inputs | Alto | Medium/Low |

| Adapt to automation | Support (recommended) | Basically not supported |

| Cleaning method | Self-cleaning | Solvent cleaning |

| Recommended yield | More than 1000 pieces/day | Less than 500 pieces/day |

- If your goal is to establish an automated and standardized plant, it is recommended to prioritize high-pressure systems.

- For customers with limited budgets or in the verification stage, they can start with low-voltage systems and upgrade later.

- We can recommend the most suitable foaming system solution based on your formula viscosity, daily production target, and operating team configuration.

Sistema de moldes

Material del molde:

- Buena conductividad térmica, calentamiento rápido, control de temperatura estable → acortan la reacción de espumación y el enfriamiento, y mejoran la capacidad de producción

- Diseño ligero para facilitar el manejo manual o el desmoldeo y agarre automáticos.

- El tratamiento superficial es liso y permite diversos procesos de superficie, como el pulido espejo y el grabado de texturas.

- Alta resistencia a la corrosión y a la erosión de la materia prima de poliuretano.

- Larga vida útil, hasta 20.000-300.000 ciclos en promedio.

- Superficie pulida: ideal para almohadas de tacto suave, de aspecto sencillo.

- Tejido con efecto anticorrosión: mejora el rendimiento antideslizante y simula el aspecto de la tela.

- Revestimiento de espejo: se utiliza para personalizaciones de alta gama para realzar la textura.

Base del molde:

El bastidor del molde se utiliza para soportar y fijar el molde, lo que afecta directamente a la eficiencia de apertura y cierre, así como a la seguridad operativa del mismo. Según el grado de automatización y los requisitos de capacidad de producción, el bastidor del molde se divide principalmente en las siguientes categorías.

- La apertura y el cierre del molde se realizan accionando manualmente la manivela o palanca del marco del molde.

- Estructura sencilla, bajo coste, ideal para producción en lotes pequeños o para pruebas.

- La intensidad del trabajo es alta y el operador necesita tener cierta experiencia.

2) Marco de molde de apertura y cierre automático

- Utilizar un accionamiento eléctrico o hidráulico para lograr la apertura y el cierre automáticos del molde.

- Mejorar la eficiencia de la producción y reducir los errores humanos

- Adaptable a líneas de producción automatizadas, compatible con el uso de brazos robóticos o dispositivos de agarre

3) Bastidor auxiliar neumático para moldes

- Además del sistema manual de apertura y cierre, se añade un sistema neumático de asistencia.

- Reducir significativamente la intensidad y la dificultad del trabajo de los operadores.

- Adecuado para fábricas con capacidad de producción media y que desean ahorrar costes laborales.

Consejos prácticos:

- Si el objetivo es el mercado de gama media-alta, se recomienda priorizar el uso de moldes de aluminio grabados o con tratamiento de espejo para mejorar la apariencia y la textura del producto.

- El número recomendado de moldes es de 1,2 a 1,5 veces el número de estaciones de trabajo para satisfacer las necesidades de reemplazo de moldes, mantenimiento y programación flexible de la producción.

- Es necesario utilizar el molde con una máquina de control de temperatura para garantizar la calidad del espumado y el tiempo de fraguado.

máquina de temperatura de molde

La máquina de control de temperatura del molde es un equipo importante para ajustar la temperatura del mismo. Mediante la circulación de un fluido de calentamiento o enfriamiento (generalmente aceite o agua caliente), el molde se mantiene dentro del rango de temperatura constante establecido para garantizar reacciones químicas uniformes y estables durante el proceso de espumado.

Funciones principales y ventajas:

- Alta uniformidad de temperatura: evita el sobrecalentamiento o enfriamiento excesivo localizado del molde, previene la formación irregular de espuma, defectos de espumación o deformación del producto.

- Reducir el tiempo de formación de espuma y enfriamiento: Acelerar la velocidad de curado, mejorar el ritmo y la capacidad de producción.

- Prolongar la vida útil del molde: El funcionamiento a temperatura constante reduce el estrés térmico y evita grietas o deformaciones en el molde.

- Admite el cambio entre moldes múltiples: configure el control de temperatura multietapa mediante el programa para cumplir con los requisitos de proceso de diferentes moldes o productos.

Referencia de parámetros técnicos:

- Rango de control de temperatura: común 30 ℃~ 150 ℃

- Precisión del control de temperatura: ± 1 ℃

- Medio calefactor: aceite caliente o agua circulante (opcional según el tamaño del equipo y la demanda).

- Circulación de flujo y presión: Garantizar un flujo uniforme y de alta velocidad del fluido caloportador, y responder rápidamente a los cambios de temperatura.

Máquina perforadora (opcional)

- Múltiples métodos de punzonado: punzonado mecánico, neumático o láser; elija la solución adecuada según los requisitos del producto.

- Alto grado de automatización: permite el taladrado automático en la línea de montaje, garantizando una posición y un espaciado de taladrado precisos y uniformes.

- Se adapta a una variedad de materiales y durezas: puede manejar materiales de espuma de poliuretano de diferentes densidades y espesores.

- Ahorro energético y protección del medio ambiente: el equipo funciona de forma estable, genera poco ruido y cumple con las normas de seguridad industrial.

- Almohada suave de alta gama, mejora la transpirabilidad, reduce la sensación de calor.

- Las almohadas con funciones especiales, como las de masaje o las de atención médica, optimizan la circulación del aire.

- Productos personalizados para satisfacer las necesidades individuales de los clientes.

- Determinar si se necesita equipo de punzonado en función del diseño del producto y el posicionamiento en el mercado.

- Para las fábricas de marcas que buscan una competitividad diferenciada, los equipos de punzonado son una herramienta eficaz para mejorar el valor añadido del producto.

Máquina para romper burbujas (opcional)

- Eliminación eficaz de burbujas grandes: se utilizan cuchillas giratorias de alta velocidad o tecnología ultrasónica para destruir las burbujas grandes en la espuma.

- Mejora la uniformidad de los poros: optimiza la microestructura interna de la espuma y mejora la estabilidad de sus propiedades físicas.

- Reducir la tasa de defectos: reducir problemas de calidad como fracturas y deformaciones causadas por poros irregulares.

- Mejorar la consistencia del producto: garantizar una calidad estable del producto entre lotes.

- Adecuado para almohadas de alta gama con altos requisitos de finura de la espuma.

- Selección flexible en función del tamaño de la línea de producción y del presupuesto.

Sistema de desmoldeo

- Ventajas: baja inversión en equipos, operación flexible, apto para producción de lotes pequeños o de múltiples variedades.

- Desventajas: alta intensidad de mano de obra, baja eficiencia, susceptible a factores humanos, escasa estabilidad de calidad

- Ventajas: Mejora la velocidad de desmoldeo, reduce los costes laborales, mejora la consistencia y la seguridad del producto.

- Adecuado para líneas de producción automatizadas medianas y grandes.

Si desea obtener más información sobre la línea de producción de almohadas de espuma viscoelástica de PU, no dude en contactarnos.

Lista de reproducción

Reseña de la línea de producción de almohadas de memoria

La línea de producción de almohadas de espuma viscoelástica UREXCEED ha recibido numerosos elogios por parte de los clientes debido a su excepcional eficiencia, precisión en el moldeo y rendimiento fiable. Gracias a su tecnología de vanguardia y opciones personalizables, ofrece una calidad constante a la vez que optimiza los procesos de producción. Los clientes destacan su facilidad de uso, durabilidad y capacidad para satisfacer las altas exigencias del mercado, lo que la convierte en la solución ideal para las empresas que buscan mejorar la productividad y la calidad de sus productos.

Hemos estado utilizando esta línea de producción durante más de un año y ha sido un punto de inflexión para nuestro negocio. El diseño duradero y el rendimiento estable garantizan que podamos satisfacer la alta demanda del mercado sin tiempos de inactividad. El soporte posventa también ha sido excelente.

Sofía Nguyen VietnamEsta línea de producción nos ha permitido aumentar rápidamente la producción manteniendo una calidad de primer nivel. Las almohadas están perfectamente moldeadas y la máquina funciona sin problemas con un mantenimiento mínimo. Es la mejor inversión que hemos hecho para nuestra fábrica.

Liam Smith Reino UnidoLa calidad de las almohadas producidas por esta máquina es excepcional. Nuestros clientes han notado la mejora y, como resultado, nuestras ventas han aumentado. ¡El servicio y el soporte técnico de UREXCEED también han sido fantásticos!

María González MéxicoEstamos impresionados con el rendimiento de la línea de producción de almohadas de espuma viscoelástica. La precisión y la consistencia del resultado son incomparables. Es duradera, eficiente y vale cada centavo. ¡Excelente servicio del equipo también!

Oliver Brown AustraliaEsta línea de producción nos ha ayudado a mejorar la calidad del producto y a reducir el tiempo de producción. Es confiable y está diseñada para durar, lo que la hace perfecta para nuestras necesidades de fabricación. Estamos muy satisfechos con los resultados.

Anastasia Ivanova RusiaSi necesita una línea de producción de almohadas de gel, también puede contactarnos.

La línea de producción de almohadas de espuma viscoelástica ha transformado nuestro proceso de fabricación. La precisión en el moldeado y la consistencia en la calidad son excepcionales. Es fácil de operar y mantener, y la eficiencia de producción ha superado nuestras expectativas. ¡Muy recomendable!

Juan Martínez EE.UU