Línea de producción de asientos para automóviles

UREXCEED polyurethane automotive seat production line is designed for efficient and high-precision molding of automotive seats, meeting the stringent requirements of modern automotive industries for comfort, safety, and environmental standards. The full production line includes a máquina de espuma, moldes y marcos de moldes, integrados con sistemas de control avanzados para garantizar los más altos estándares de calidad en todo el proceso de producción.

Flujo de proceso de UREXCEED PU Car Seat Production Line

Paso 1

Paso 2

Paso 3

Paso 4

Paso 5

Acerca de UREXCEED Línea de producción de asientos para automóviles

UREXCEED offers a wide range of customizable lines, including rotary lines, carousel lines and banana lines, designed to meet the specific needs of different manufacturing processes. Regardless of the complexity or scale of your production needs, UREXCEED can provide you with the right line to ensure maximum productivity and minimize downtime. Our comprehensive solutions are designed to increase efficiency, reduce operating costs and enhance the overall manufacturing process.

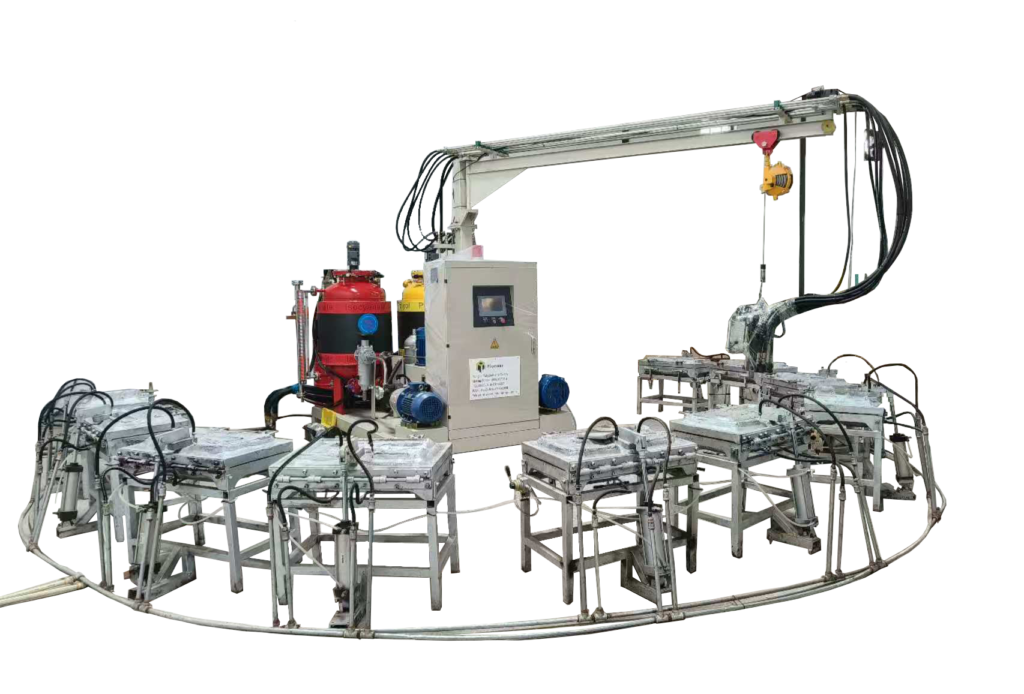

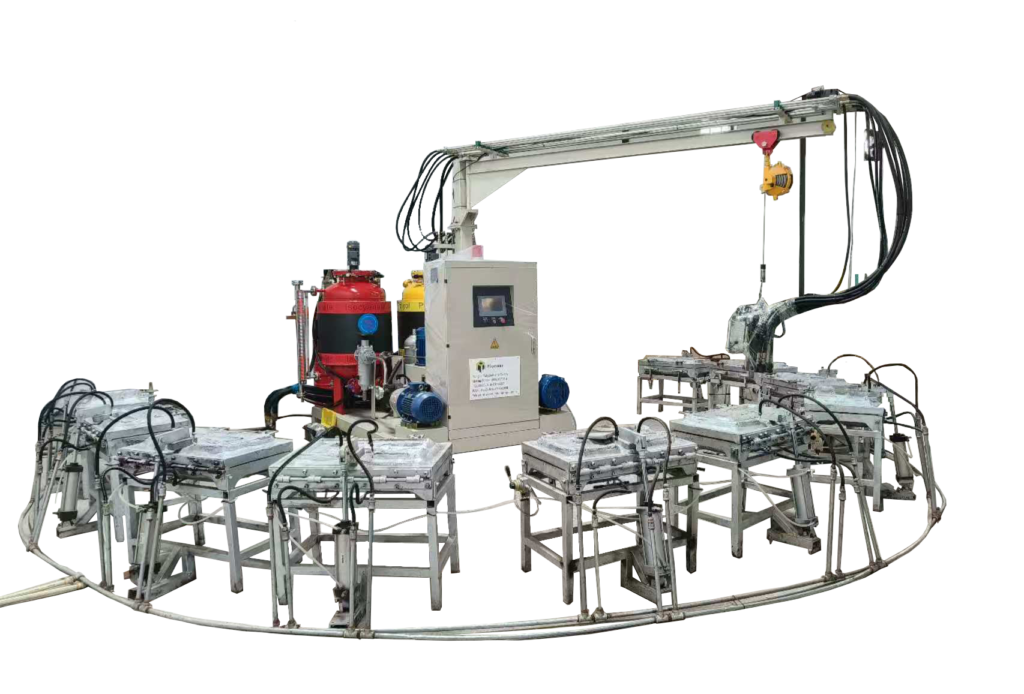

Línea de producción de carrusel

Ideal para producciones simples, de ciclo corto y con una estructura sencilla.

Línea de producción de carrusel

Ideal para producciones simples, de ciclo corto y con una estructura sencilla.

Aplicaciones: La línea de producción UREXCEED es adecuada para procesos de fabricación relativamente simples, como recubrimiento, prensado u otras operaciones. Se utiliza comúnmente para la producción de lotes pequeños o productos con requisitos de proceso específicos.

Características: Compacta y sencilla, la línea de producción de carrusel es ideal para la fabricación de un solo producto o para necesidades de producción de ciclo corto y a pequeña escala.

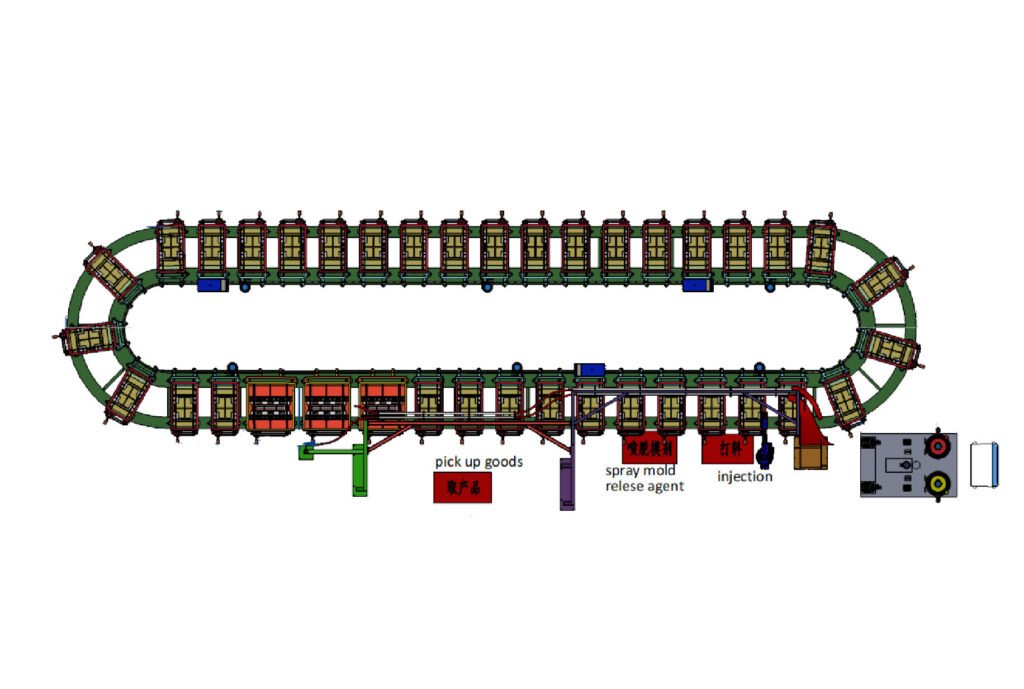

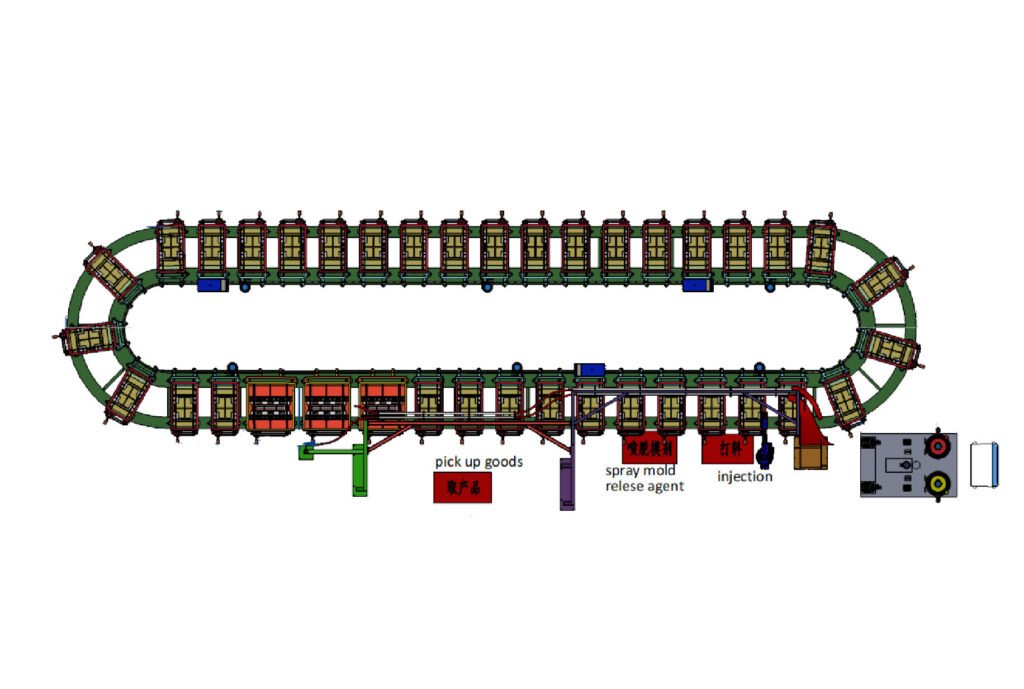

Línea de producción rotativa

Adecuado para producción automatizada a gran escala y de múltiples pasos.

Línea de producción rotativa

Adecuado para producción automatizada a gran escala y de múltiples pasos.

Aplicaciones: Las líneas de producción rotativas UREXCEED se utilizan a menudo para productos que requieren múltiples procesos y producción continua. Son especialmente eficaces en la producción en masa y en entornos altamente automatizados.

Características: Las líneas de producción rotativas, que ofrecen una gran flexibilidad, se pueden configurar con varias estaciones de trabajo. Son adecuadas para tareas de producción a largo plazo y de alta eficiencia, que suelen implicar productos más complejos.

Línea de producción de plátano

Diseñado para productos que requieren formas especializadas o pistas de procesamiento curvas, ofreciendo alta flexibilidad.

Línea de producción de plátano

Diseñado para productos que requieren formas especializadas o pistas de procesamiento curvas, ofreciendo alta flexibilidad.

Aplicaciones: Este tipo de línea de producción se utiliza para procesos que requieren pistas curvas o formas específicas. Es especialmente adecuada para manipular materiales flexibles o fabricar productos con formas complejas.

Características: Conocida por su adaptabilidad, la línea de producción de banana puede manejar piezas de trabajo con formas o ángulos únicos, lo que la hace ideal para productos que necesitan un procesamiento con ángulos variables o formas específicas.

Solución integral De la línea de producción de asientos de automóvil

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

Maquina de espuma

Moho

Mold Temperature Control Machine

Materia prima

Contáctenos para una cotización completa

Las máquinas UREXCEED son 30% más baratas que las europeas

Preguntas frecuentes De la línea de producción de asientos de automóvil

Uniform foaming is achieved by precisely controlling the raw material mix ratios, injection pressure, and mold temperature. The mold temperature controller plays a key role in maintaining consistent heat distribution, ensuring that the foam expands evenly and cures uniformly.

The mold temperature machine (or mold temperature controller) heats or cools the mold to maintain a constant temperature. This is critical for controlling the foaming reaction, ensuring proper material flow, and ultimately achieving a high-quality, consistent product.

Regular maintenance is essential. It includes:

- Routine inspections and cleaning of molds, nozzles, and mixing heads.

- Calibration of dosing pumps and monitoring of injection pressure.

- Preventive maintenance schedules to reduce downtime and maintain optimal production efficiency.

In case of issues, check the following:

- Raw Material Mix: Ensure the correct ratios of polyol and isocyanate.

- Injection Parameters: Verify that the injection pressure and speed are set correctly.

- Mold Temperature: Confirm that the mold is at the required temperature.

- Release Agent Application: Ensure even application to prevent sticking and surface defects.

Safety and environmental compliance are ensured by:

- Adhering to strict operational protocols and safety guidelines.

- Using eco-friendly raw materials and release agents.

- Implementing proper ventilation and waste management systems to control emissions and protect workers.

Operators receive comprehensive training that includes:

- Detailed operation manuals and on-site training sessions.

- Remote technical support and troubleshooting assistance.

- Continuous updates on best practices to ensure efficient and safe production.

Lista de reproducción

Transaction Case Of UREXCEED PU Car Seat Production Line

Good Review Of Car Seat Production Line

UREXCEED provide a comprehensive one-stop service for all your manufacturing needs, offering not just production lines but also a full range of supporting solutions to streamline your operations. In addition to our highly efficient production lines, UREXCEED supply top-quality raw materials, machinery, molds, and other essential auxiliary equipment, ensuring seamless integration across your entire production process. Whether you’re looking for specific components, custom molds, or specialized machinery, UREXCEED offer everything you need to optimize production, reduce lead times, and maintain consistent product quality. Our holistic approach allows you to source all required elements from a single trusted partner, simplifying procurement and enhancing operational efficiency. With our one-stop service, we help you reduce costs, improve workflow, and focus on scaling your business with confidence.

La línea de producción de UREXCEED es confiable y eficiente, lo que aumenta la producción y reduce el tiempo de inactividad. Estamos muy contentos con el equipo y el soporte.

Sarah Müller AlemaniaEstamos muy satisfechos con la línea de producción de asientos de UREXCEED. Mejoró la eficiencia y garantizó una alta calidad. El equipo brindó un excelente soporte técnico. ¡Muy recomendable!

Juan Pérez MéxicoNuestra eficiencia de producción aumentó en 30% con la línea de producción de asientos de UREXCEED. Las funciones inteligentes redujeron los errores y el servicio fue excelente. ¡Muy satisfecho!

Abdul Aziz Emiratos Árabes UnidosLa línea de producción de UREXCEED es estable, eficiente y altamente automatizada. Minimiza los errores y aumenta la producción. ¡La recomiendo mucho!"

Carlos Mendoza EspañaHemos visto excelentes resultados con esta máquina de espuma en aerosol. Proporciona un recubrimiento uniforme y es fácil de controlar.

La máquina de recubrimiento funciona a la perfección y aplica la cantidad justa de pegamento en cada aplicación. Es una gran incorporación a nuestra línea de producción.

Eliot Davis Director de operaciones

A Mexican automotive parts manufacturer sought to improve seat production efficiency and ensure stable product quality. They required a highly efficient and automated polyurethane car seat production line, including a high-pressure polyurethane foaming machine, mold temperature controller, seat molds, and a production line. After multiple discussions, we provided a customized, energy-efficient solution, optimizing key processes such as mold heating, release agent spraying, material injection, and foaming. The client was impressed by our equipment stability, uniform foaming, and one-stop service, leading to a successful order. After installation, we offered remote technical support and on-site training to ensure smooth production. The line is now fully operational, delivering high product yield and helping the client enhance efficiency while reducing costs.

México