Common Faults of Polyurethane High-Pressure Machines and Their Solutions

Polyurethane high-pressure machines are complex systems that can experience various operational issues during their lifecycle, from pump malfunctions to temperature control problems. Understanding these common faults and implementing effective troubleshooting solutions is crucial for maintaining production efficiency, extending equipment lifespan, and ensuring consistent product quality.

Puntos clave

- Pumping system failures often result from cavitation, worn seals, or contaminated hydraulic fluid

- Temperature control issues can cause improper chemical reactions and affect final product quality

- Regular preventative maintenance is the most cost-effective strategy to avoid major machine breakdowns

- Mixing head problems typically manifest as improper component ratios or incomplete mixing of materials

- Electrical and control system faults require systematic diagnosis following specific troubleshooting procedures

Comprensión de las máquinas de alta presión de poliuretano

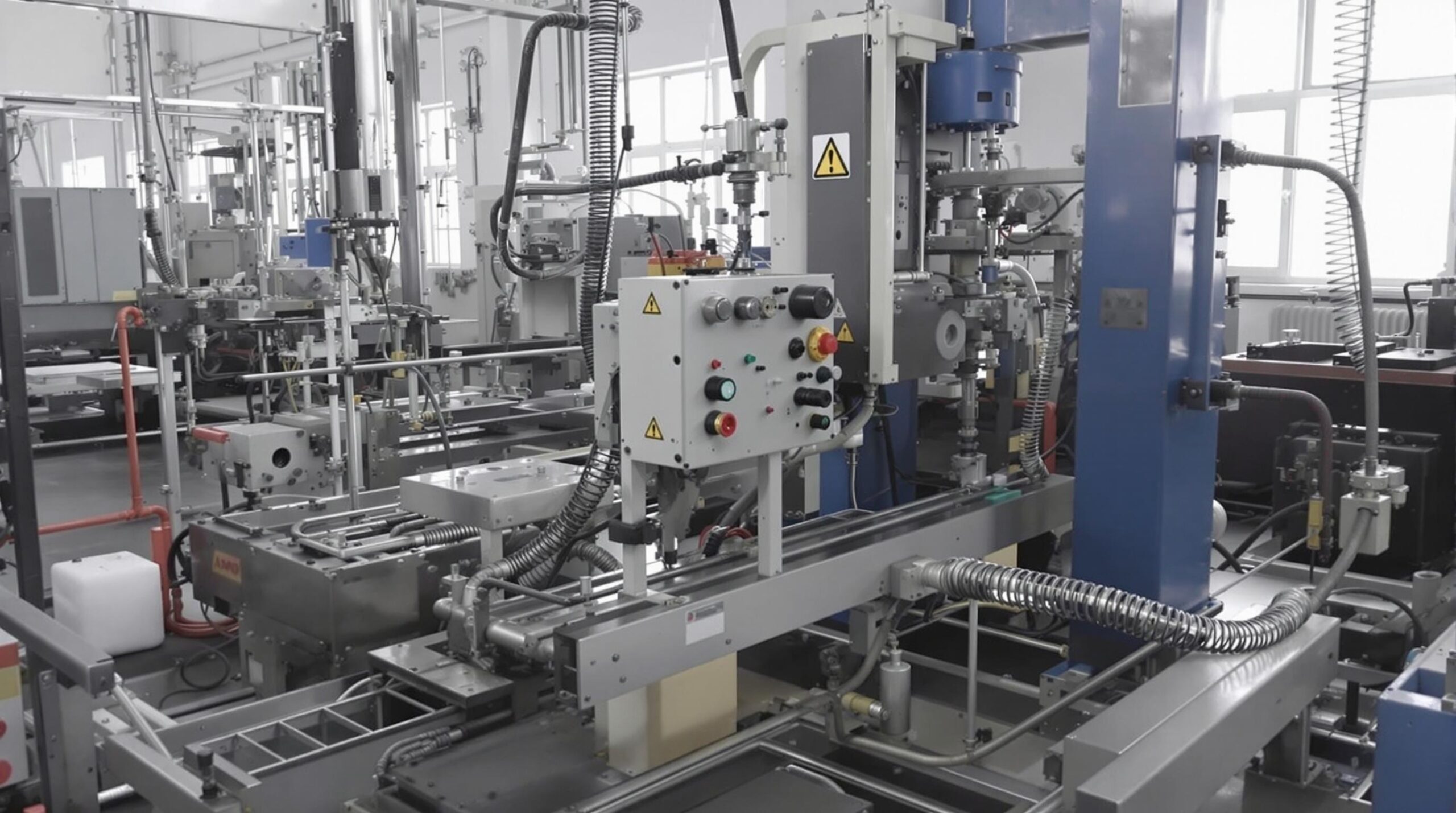

Polyurethane high-pressure machines are specialized equipment used in manufacturing a wide range of products including furniture, automotive components, insulation, and footwear. These machines work by precisely mixing and dispensing polyol and isocyanate components under high pressure to create polyurethane foam or elastomers.

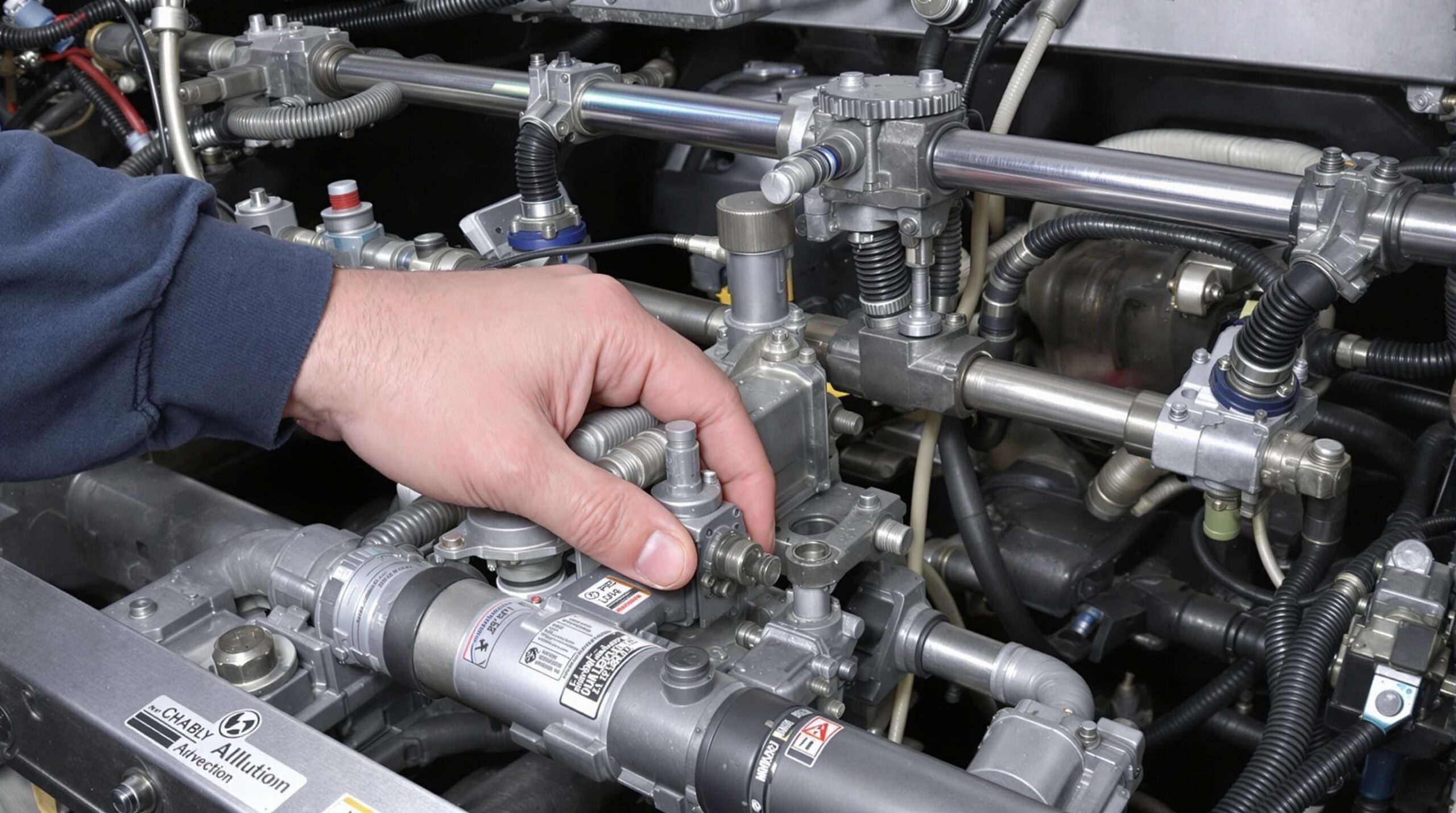

The basic components of a high-pressure polyurethane machine include pumping systems, heating elements, mixing heads, control systems, and material supply units. Each component plays a critical role in the production process, and a malfunction in any one area can lead to production delays, material waste, or quality issues.

Pumping System Failures

The pumping system is the heart of a polyurethane high-pressure machine, responsible for delivering the chemical components at the correct pressure and ratio. Common pumping system failures include cavitation, seal deterioration, and hydraulic fluid contamination.

When pumps develop cavitation, it's often due to air infiltration in the suction line or insufficient material supply. This issue causes erratic pressure readings, noisy operation, and potentially damaged pump components. To resolve cavitation problems:

- Check and tighten all connections in the suction line

- Ensure material drums have sufficient levels

- Clean or replace clogged filters in the suction line

- Verify the material viscosity is appropriate for the pump design

Seal failures are another frequent pumping system issue. As seals wear out, they allow material leakage or cross-contamination between components. Signs of seal failure include visible leakage around pump connections, pressure fluctuations, or off-ratio mixing. Solutions include:

- Regular inspection of seals for wear or damage

- Replacement of seals according to manufacturer's recommended schedule

- Proper cleaning of seal surfaces during replacement

- Using only manufacturer-approved seal materials

Hydraulic fluid contamination can cause pump failures through increased wear and damage to precision components. This contamination may come from external sources or internal degradation of the hydraulic system. To address hydraulic fluid issues:

- Implement a regular schedule for hydraulic fluid analysis

- Change hydraulic fluid and filters according to manufacturer recommendations

- Check for and repair any sources of external contamination

- Flush the hydraulic system when replacing fluid

Temperature Control Problems

Proper temperature control is essential for polyurethane processing, as it directly affects material viscosity, reaction rates, and final product properties. Temperature control issues often manifest as inconsistent foam quality or processing difficulties.

Heating element failures are a common source of temperature control problems. When heating elements malfunction, they may provide insufficient or excessive heat, leading to improper chemical reactions. Solutions for heating element issues include:

- Regular inspection of heating elements for signs of damage

- Testing electrical continuity of heating circuits

- Cleaning heating surfaces to ensure efficient heat transfer

- Replacing damaged heating elements with exact specification matches

Temperature sensor failures can also disrupt operations by providing inaccurate readings to control systems. This causes the system to apply incorrect heating or cooling, even when heating elements are functioning properly. To address temperature sensor problems:

- Calibrate temperature sensors regularly

- Check sensor wiring for loose connections or damage

- Verify sensor readings against secondary temperature measurement devices

- Replace sensors showing inconsistent or erratic readings

Heat exchanger efficiency can decline over time due to material buildup or mechanical issues. When heat exchangers don't function properly, they fail to maintain consistent material temperatures. To restore proper heat exchanger function:

- Clean heat exchanger surfaces according to maintenance schedule

- Check for proper flow rates through heat exchanger circuits

- Inspect for leaks or cross-contamination between fluid systems

- Descale heat exchangers if mineral deposits have formed

Mixing Head Malfunctions

The mixing head is where the polyol and isocyanate components combine under high pressure to initiate the polyurethane reaction. Mixing head problems directly affect product quality and consistency. Common mixing head issues include clogged nozzles, valve failures, and self-cleaning mechanism problems.

Clogged injection nozzles prevent proper material flow and mixing, resulting in off-ratio mixing or streaking in the final product. To address clogged nozzles:

- Implement a regular cleaning schedule for mixing heads

- Use appropriate solvents recommended by the manufacturer

- Disassemble and inspect nozzles for material buildup

- Replace damaged nozzles rather than attempting repair

Mixing head valve failures can cause material leakage or prevent proper shutoff between shots. This issue leads to material wastage and contamination of the mixing chamber. Solutions include:

- Regular inspection of valve components for wear or damage

- Cleaning valve seats and sealing surfaces

- Checking hydraulic pressure to valve actuators

- Replacing worn valve components with original equipment parts

Self-cleaning mechanisms may fail to properly clear the mixing chamber between shots, leading to partial blockages and eventually complete mixing failure. To maintain self-cleaning system functionality:

- Verify hydraulic pressure to the self-cleaning piston

- Check for smooth operation of the self-cleaning mechanism

- Inspect self-cleaning pistons for wear or damage

- Clean material residue from self-cleaning components

Material Supply Issues

Consistent material supply is crucial for high-pressure polyurethane machines. Supply issues can result in production interruptions and quality problems. Common material supply issues include material contamination, improper storage, and feed system failures.

Material contamination can occur from various sources including moisture, incompatible materials, or environmental contaminants. Contaminated materials cause unpredictable reactions, foam collapse, or improper curing. To prevent and address contamination:

- Store materials according to manufacturer recommendations

- Use dry nitrogen blankets for moisture-sensitive materials

- Implement proper drum changing procedures to minimize exposure

- Filter materials during transfer to machine supply tanks

Feed system failures prevent consistent material delivery to the high-pressure pumps. These failures can include transfer pump issues, filter clogging, or supply line restrictions. Solutions include:

- Regular maintenance of transfer pumps and supply systems

- Scheduled filter inspection and replacement

- Monitoring supply line temperatures to maintain proper viscosity

- Checking for and removing any kinks or restrictions in supply lines

Material degradation due to improper storage or excessive age can cause significant processing problems. Materials that have exceeded their shelf life may react improperly or fail to cure correctly. To manage material quality:

- Implement first-in, first-out inventory management

- Monitor and document material storage conditions

- Test suspect materials before use in production

- Properly dispose of expired or degraded materials

Electrical and Control System Faults

Modern polyurethane high-pressure machines rely on sophisticated electrical and control systems to maintain precise operating parameters. Electrical and control system faults can cause unpredictable machine behavior and processing errors.

Control panel malfunctions may result from damaged components, software errors, or power supply issues. These malfunctions prevent proper machine operation and monitoring. To address control panel issues:

- Check for error codes and consult machine documentation

- Verify power supply stability and quality

- Back up control system programs before troubleshooting

- Contact manufacturer support for complex control issues

Sensor failures provide incorrect information to control systems, leading to improper machine adjustments. Common sensor issues include pressure transducer failures, flow meter inaccuracies, and position sensor malfunctions. Solutions include:

- Regular calibration of all sensors

- Inspection of sensor wiring and connections

- Verification of sensor readings against known standards

- Replacement of sensors showing signs of drift or failure

Wiring and connection problems can cause intermittent machine errors that are difficult to diagnose. These issues may result from vibration, environmental factors, or installation errors. To address wiring problems:

- Inspect all electrical connections for tightness and corrosion

- Check wiring harnesses for damage or wear

- Use proper diagnostic tools to trace intermittent faults

- Implement proper cable management to prevent damage

Hydraulic System Issues

The hydraulic system powers many critical functions in high-pressure polyurethane machines, including pumps, mixing head movement, and valve actuation. Hydraulic system failures can cause widespread operational problems.

Hydraulic pump failures reduce system pressure and prevent proper operation of hydraulically powered components. Signs of pump failure include unusual noise, excessive heat, or inability to maintain pressure. To address hydraulic pump issues:

- Check hydraulic fluid levels and condition

- Inspect pump inlet filters for restrictions

- Monitor pump operating temperature

- Measure actual output pressure against specifications

Valve malfunctions in the hydraulic system prevent proper fluid direction and control. This can result in erratic component movement or failure to perform required functions. Solutions for valve issues include:

- Clean or replace solenoid valve components

- Check electrical signals to valve actuators

- Inspect valve spools for wear or contamination

- Verify proper hydraulic pressure at valve inlets

Hydraulic fluid leaks waste fluid, create safety hazards, and potentially cause system pressure loss. Identifying and repairing leaks is essential for system integrity. To address hydraulic leaks:

- Regularly inspect all hydraulic connections and components

- Tighten loose fittings to specified torque

- Replace damaged seals, O-rings, or gaskets

- Clean leaked fluid thoroughly to allow for future leak detection

Preventative Maintenance Best Practices

Implementing a comprehensive preventative maintenance program is the most effective way to reduce machine downtime and extend equipment life. Proactive maintenance approaches catch small issues before they develop into major failures.

Daily inspection routines should be established to monitor critical machine functions. These quick inspections can identify developing problems before they cause production interruptions. Daily inspections should include:

- Visual checks for leaks or damage

- Monitoring of pressure and temperature readings

- Brief functional tests of critical components

- Documentation of any unusual conditions or changes

Scheduled maintenance intervals based on manufacturer recommendations or operating hours ensure that critical components are serviced before failure. A comprehensive scheduled maintenance program includes:

- Complete cleaning of mixing heads and other material-contact surfaces

- Replacement of filters, seals, and other wear items

- Calibration of sensors and control systems

- Lubrication of moving components

- Testing of safety systems and emergency stops

Maintenance record keeping provides valuable historical data for identifying recurring issues and planning future maintenance. Detailed documentation helps maintenance teams recognize patterns and make informed decisions. Effective record keeping includes:

- Logging all maintenance activities with dates and personnel information

- Tracking part replacements and repair costs

- Noting unusual findings or recurring issues

- Recording machine operating parameters for trend analysis

Troubleshooting Methodology

When machine faults occur despite preventative maintenance, a systematic troubleshooting approach helps identify and resolve issues efficiently. Following a structured diagnostic process saves time and prevents misdiagnosis.

Initial assessment should gather information about the problem without making assumptions about the cause. This phase establishes a clear understanding of the issue before taking action. The initial assessment includes:

- Interviewing operators about what they observed

- Reviewing machine logs and error codes

- Performing a quick visual inspection

- Checking basic operating parameters

Systematic testing isolates the problem by checking each system component methodically. This approach prevents random component replacement and focuses on the actual cause. Systematic testing involves:

- Testing individual components in isolation when possible

- Moving from simple checks to more complex diagnostics

- Using proper test equipment for accurate measurements

- Documenting test results for future reference

Root cause analysis identifies the underlying issue rather than just addressing symptoms. Finding and correcting the fundamental problem prevents recurrence and improves machine reliability. Effective root cause analysis includes:

- Questioning why each failure occurred

- Looking for connections between seemingly unrelated issues

- Considering operating conditions and environmental factors

- Implementing corrective actions that address the true cause

When to Seek Professional Assistance

While many polyurethane machine issues can be resolved by in-house maintenance teams, certain situations warrant professional assistance. Recognizing when to call for specialized help prevents further damage and reduces downtime.

Complex electrical or control system issues often require expertise beyond typical maintenance capabilities. These problems might involve proprietary software, specialized diagnostic tools, or extensive system knowledge. Signs that indicate the need for professional electrical assistance include:

- Unexplained error codes that don't match documentation

- Control system crashes or random resets

- Communication failures between system components

- Complete loss of control system functionality

Major mechanical failures typically require professional intervention due to the specialized tools and expertise needed for repair. These failures may involve critical machine components that affect overall operation. Situations requiring professional mechanical assistance include:

- Catastrophic pump failures

- Major hydraulic system damage

- Structural issues with machine frames or mounts

- Specialized component replacements requiring precision alignment

Recurring issues that resist standard troubleshooting approaches signal deeper problems that need professional diagnosis. These persistent problems often have multiple contributing factors or unusual root causes. Consider professional assistance when:

- The same issue returns despite repeated repairs

- Problems appear random or intermittent

- Multiple systems show related symptoms

- Standard diagnostic approaches yield inconsistent results

Upgrading and Modernizing Older Machines

Older polyurethane high-pressure machines can benefit from strategic upgrades that improve reliability, efficiency, and functionality. Modernization can extend useful machine life while reducing maintenance requirements.

Control system upgrades replace outdated electronics with modern components that offer improved reliability and additional features. These upgrades can transform the capabilities of older machines. Benefits of control system modernization include:

- Improved diagnostic capabilities

- Enhanced data logging and analysis

- Better interface with other production systems

- Easier parts availability for future repairs

Pump and hydraulic system updates can improve efficiency and reduce maintenance requirements. Modern components often offer superior performance and reliability compared to older designs. Potential hydraulic and pump upgrades include:

- More efficient pump designs that reduce energy consumption

- Improved sealing systems that extend service intervals

- Modern valves with better control characteristics

- Updated filtration systems that better protect components

Mixing technology improvements can enhance product quality and reduce material waste. Advancements in mixing head design offer better mixing efficiency and reduced maintenance requirements. Mixing technology upgrades might include:

- Self-cleaning mixing heads that reduce solvent usage

- Improved nozzle designs for better component atomization

- Enhanced material recirculation systems

- Direct material injection systems that reduce waste

FAQs About Polyurethane High-Pressure Machine Faults

How often should I clean the mixing head on my polyurethane machine?

Mixing heads should be cleaned at the end of each production shift or when changing materials. For continuous operations, implement scheduled cleaning breaks every 8-12 hours to prevent buildup and ensure consistent mixing quality.

What causes ratio fluctuations in my polyurethane dosing system?

Ratio fluctuations typically result from pump issues, material supply problems, or sensor inaccuracies. Check for air in the material lines, worn pump seals, clogged filters, or pressure transducer failures as these are the most common causes.

Why does my machine develop hydraulic leaks shortly after maintenance?

Post-maintenance leaks often occur due to improper fitting tightening, damaged seals during assembly, or using incorrect replacement parts. Always follow manufacturer torque specifications, inspect seals before installation, and use only recommended genuine or equivalent parts.

What's the most common cause of temperature control failures?

The most common causes are faulty temperature sensors, heating element failures, or control system issues. Regular calibration of temperature sensors and inspection of heating elements can prevent most temperature control problems.

How can I determine if a mixing problem is mechanical or chemical?

To distinguish between mechanical and chemical mixing issues, first check machine parameters like pressure, temperature, and ratio. If these are correct, examine the mixing head for mechanical problems. If mechanical systems appear normal, then investigate material quality, age, or compatibility issues as potential chemical causes.