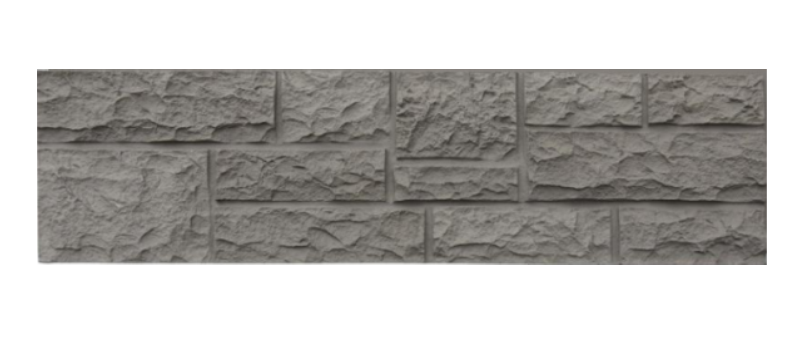

Faux Stone Production Line

About UREXCEED PU Culture Stone Production Line

Polyurethane Foam Machine

UREXCEED® Polyurethane Foam Machine polyurethane foam machine is the core equipment of the production line, responsible for mixing the polyurethane raw materials and foaming to create the base structure of the culture stone. Its main functions and features include:

- High-pressure and low-pressure foam options: Depending on the product requirements, different types of foam machines (high-pressure or low-pressure) can be selected to ensure uniform and stable foaming results.

- Precise ratio control: The material mixing ratio is precisely controlled to ensure consistent product quality by maintaining the correct proportions of raw materials during the foaming process.

- Versatility: The foam machine can produce polyurethane culture stones in various densities and colors, and can adjust parameters based on different production needs, enabling customized production.

PU Faux Stone Mold

- Customized Design: Polyurethane culture stone molds can be customized according to client requirements, creating different shapes, sizes, and textures to meet a variety of architectural and decorative styles. Whether it’s rustic stone patterns, wood-like textures, or modern designs, customization is easily achievable.

- High-precision Manufacturing: The molds are manufactured using high-precision equipment, ensuring smooth, flawless surfaces and a long service life. The precise molds guarantee uniformity in the shape and size of each culture stone, improving production efficiency.

- Diverse Mold Materials: Mold materials can be chosen based on production requirements, with commonly used materials such as aluminum alloy, steel, and special plastics. Different materials help the molds adapt to various production environments, ensuring durability and stability.

- Efficient Mold Replacement and Maintenance: During production, molds can be quickly replaced to accommodate different styles. Regular inspection and maintenance are important to ensure molds remain in good condition and do not affect product quality.

Automation Control System

The automation control system is an essential part of the polyurethane culture stone production line, responsible for monitoring and adjusting various parameters during the production process to ensure stability and efficiency. Main functions include:

- Automated Production Process: The system automates the entire production process, from material ratio mixing, foaming, mold pouring, to curing, reducing manual operation and improving efficiency.

- Real-time Monitoring: The central control system monitors production line data in real-time, including temperature, pressure, and foaming time, ensuring that each step meets quality standards.

- Remote Operation: The system provides remote control and diagnostic capabilities, allowing adjustments to production line parameters and quick resolution of issues, ensuring continuous operation.

Curing and Forming System

After foaming in the mold, the polyurethane culture stone needs to be cured and formed to achieve its final product shape. The curing system typically includes temperature-controlled boxes or ovens to accelerate the hardening process. Main features include:

Working Principle Of UREXCEED PU Faux Stone Production Line

The production process of UREXCEED® polyurethane culture stone involves several precise steps, from raw material preparation to final product delivery. Each step is carefully controlled to ensure the quality and performance of the product. Below is an overview of the main production stages:

01 Raw Material Preparation

Polyurethane raw materials (including Component A and Component B) are prepared according to a specific ratio:

- Component A: Typically polyol, which determines the hardness and density of the culture stone.

- Component B: Isocyanate, which reacts with Component A to form polyurethane foam.

Before production, the raw materials undergo quality testing to ensure they meet the required standards.

02 Material Mixing and Foaming

Use UREXCEED® high-pressure or low-pressure polyurethane foaming machine mixes Components A and B and injects the mixture into molds.

- Efficient Mixing: The foaming machine ensures even mixing of the two components, avoiding bubbles or inconsistencies during the foaming process.

- Foaming Reaction: The mixed material foams rapidly within the mold, filling every corner and forming the base structure of the culture stone.

03 Mold Filling and Shaping

The mixed polyurethane material is injected into specialized culture stone molds, which define the product’s shape and texture.

- Mold Design: Molds feature realistic stone-like textures, wood grain, or other decorative patterns to give the culture stone its distinctive appearance.

- Precise Material Injection: The material quantity is carefully controlled to ensure consistent thickness and density across all products.

- Mold Sealing and Curing: The mold is sealed, allowing the material to expand and cure inside, forming the culture stone’s final shape.

04 Curing and Demolding

After a designated curing period, the foamed material solidifies into a stable structure.

- Curing Control: Under controlled temperature conditions, the curing time is adjusted according to the desired density and thickness, typically ranging from a few minutes to several dozen minutes.

- Demolding Process: Once curing is complete, the culture stone is carefully removed from the mold, revealing clear textures and a well-formed shape.

05 Trimming and Finishing

The demolded culture stone undergoes surface finishing to ensure uniform appearance and quality.

- Trimming: Excess material around the edges is removed to achieve precise dimensions.

- Surface Treatment: Depending on customer requirements, additional treatments such as spraying, coloring, or protective coatings may be applied to enhance the stone’s appearance and performance.

If you want to know more about pu faux stone production line, feel free to contact us

Application Of UREXCEED Faux Stone Production Line

Polyurethane culture stone is widely used in architectural decoration and interior design due to its excellent performance and aesthetic appearance. It has become an indispensable material in modern building decoration. The main applications include:

Building Facade Decoration

Polyurethane culture stone is commonly used for exterior facades of residential buildings, commercial complexes, hotels, villas, and other architectural structures. Due to its lightweight, high strength, and excellent weather resistance, it not only enhances the aesthetic appeal of buildings but also reduces the structural load.Interior Decoration

Polyurethane culture stone is widely applied to interior walls, feature walls, hotel lobbies, bars, and other spaces. Its unique texture and natural colors bring depth and an artistic atmosphere to interior spaces, catering to the personalized decoration needs of modern homes and commercial spaces.Landscape and Garden Decoration

Polyurethane culture stone is also used in landscaping, garden sculptures, artificial mountains, fountains, and other decorative elements. It blends harmoniously with the natural environment, creating a rustic, natural effect that enhances the overall aesthetic appeal of gardens and outdoor spaces.Functional Architectural Decoration

Polyurethane culture stone can also be used in functional architectural applications, such as fire-resistant walls, soundproof walls, etc. Its high strength and durability provide added safety while serving decorative purposes.

Certificate Of UREXCEED Car Seat Production Line

UREXCEED®PU faux stone products meet rigorous international standards, ensuring superior quality, safety, and performance. The production process complies with industry certifications, including ISO 9001:2015 for quality management, ISO 14001:2015 for environmental management, and ISO 45001:2018 for occupational health and safety. Additionally, our materials are certified for durability, fire resistance, and environmental friendliness, guaranteeing that the PU faux stone is lightweight, strong, waterproof, and eco-conscious.

These certifications not only demonstrate our commitment to excellence but also provide customers with confidence in the reliability and sustainability of our PU faux stone products for both interior and exterior applications.