Foam Packaging Machine

- High Quality Equipment

- Remote Monitoring & Diagnostic

- Support ROI Accounting & Optimization

- Professional After-sales Service

Foam Packaging Machine

UREXCEED foam packaging machines use advanced technology to create custom foam liners that conform to the shape of the packaged items, providing superior protection against impact, shock and moisture. The machine is suitable for industries such as e-commerce, electronics and logistics where fragile products need to be securely packaged. With adjustable foam density and thickness, the foam packaging machine can be customized to specific packaging needs, thereby improving cost-effectiveness and operational efficiency.

Want to know more about specification of foam in place packaging machine?

Operation Platform Of Foam Packaging Machine

For placing mould or the item to be packed, makes the operation easier. When the machine is not in use, the platform can be used for placing cleaning agent DOP box, soak the nozzle of spray gun in the DOP solution to avoid raw materials remaining and spray gun blocking.

Spray Gun Of Foam Packaging Machine

The spray gun can mix the raw materials, switch material injecting and control the flow. Our spray gun is equipped with heating device, which can reduce the phenomenon such as undesirable foaming caused by material temperature decrease when they flow through the gun.

Main Control Cabinet Of Foam Packaging Machine

This unit concentrate all the functions of electric control part and equipment operation part:

- control the starting and stopping of feed pump

- air pressure setting

- temperature display and controlof heater

- setting and modifyingof all the operation details

- Equipment alarm device

Feed Pump Of Foam Packaging Machine

System for feeding raw materials to spray gun, adopts plunger pump with high precision and good abrasion resistance, and comes with a pressure regulating valve block to make the flow and regulation accurate.

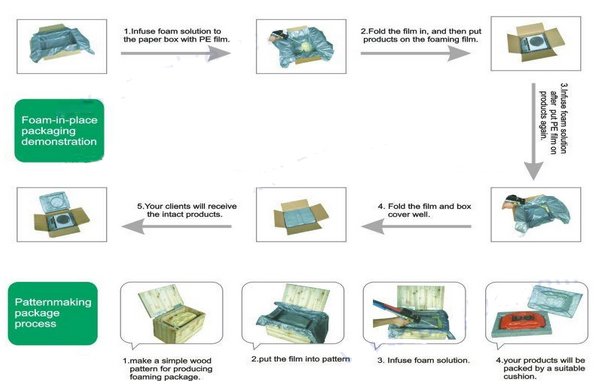

Operation Process Of UREXCEED Foam Packaging Machine

Aim the gun head at the mold, turn on the black material and white material switches on the gun head, manually or automatically control the feeding time according to production needs, and pump out the required amount of raw materials.

When feeding manually, just press the filling switch on the gun handle and the material will continue to be discharged. After reaching the required product volume, release the filling switch to stop feeding. When feeding automatically, just press the filling switch on the gun handle to distribute the corresponding materials according to the pre-set filling time.

After one mold is filled, the next mold can be filled directly. If there is no filling for a short time, the gun head must be placed in a pre-filled DOP liquid container and wiped clean to prevent the raw materials in the gun head from contacting with the air and clogging the gun head.

FAQs Of UREXCEED Foam Packaging Machine

The polyurethane foam packaging machine can achieve rapid foaming on site and reduce the storage and transportation costs of foam packaging. It can produce foam on-site according to actual packaging needs, ensuring packaging accuracy and adaptability. At the same time, it can reduce the waste of glue and foaming agent and improve efficiency.

Modern polyurethane foam packaging machines are usually equipped with automated control systems that are simple and intuitive to operate. The operator only needs to set the parameters and start the equipment, and the equipment will automatically foam and package. Some equipment also has a self-cleaning function to reduce manual intervention.

Yes, the polyurethane foam packaging machine can adjust the foaming density and hardness according to customer needs. By adjusting the ratio of components A and B and the temperature control system of the equipment, users can obtain foam materials of different densities and hardness to meet different packaging needs.

The polyurethane foam packaging machine has high production efficiency and can usually complete a baling process in a short time. Efficiency depends on foam density, foam volume and packaging needs. Modern equipment is usually equipped with automatic adjustment functions to improve production efficiency.

Maintenance of polyurethane foam packaging machines is relatively simple. Routine maintenance includes regular cleaning of nozzles, pipes, mixing chambers and other components to ensure stable foaming effect. Some equipment is also equipped with an automatic cleaning system, which can effectively reduce manual operations and reduce maintenance difficulty.

Modern polyurethane foam packaging machines adopt an efficient and energy-saving design, which consumes less energy than traditional equipment. By optimizing the foaming process and control system, the equipment can effectively reduce energy consumption and production costs.

Yes, polyurethane foam packaging machines are ideal for small batches or custom baling. The equipment can flexibly adjust the foaming volume, density and hardness according to packaging needs, adapting to production scenarios of different scales and requirements.

Clean the nozzles, pipes and mixing chamber regularly to prevent polyurethane residues from affecting the foaming effect. Check and replace wearing parts such as seals, filters, etc. to ensure normal operation of the equipment. Lubricate transmission components regularly to avoid mechanical failure.

If properly maintained and maintained, the service life of a polyurethane foam packaging machine is usually around 8-10 years. Through regular inspection and timely replacement of parts, the service life of the equipment can be extended.

Yes, the polyurethane foam packaging machine can use environmentally friendly raw materials, such as low-GWP foaming agents or water-based foaming agents, in line with modern environmental protection standards. The equipment design also complies with relevant environmental protection regulations to reduce the impact on the environment.

Yes, the polyurethane foam packaging machine can be used with other equipment (such as foam cutting machines, automated packaging lines, transportation equipment, etc.) to form a complete packaging production line to meet different packaging needs.

If you are interested in our foam packaging machine, please contact us immediately

Application Of UREXCEED Foam Packaging Machine

Packaging: UREXCEED Foam packaging machine for various abnormal and fragile articles, such as precise instruments, machines, aircraft instruments, electronic products, communication products, pump valves, pneumatic transmitters, handicraft articles, ceramic utensils, glasses, lighting products, bathing equipments,etc.

Heat preserving: Water fountain liner, portable electronic refrigerators in cars, vacuum cups, electric water heaters, general equipments, thermal insulation, solar water heaters, freezers, etc.

Package

Insulation

Filling

Good Review Of UREXCEED Foam Packaging Machine

The UREXCEED foam packaging machine has won high praise from customers in a variety of industries, including e-commerce, electronics, and logistics, for its ability to produce consistently high-quality foam packaging with minimal waste. Users report that the machine’s ability to customize the right foam liner to protect the product during transportation has significantly improved packaging speed and protection. Overall, the UREXCEED foam packaging machine is highly praised for its ability to optimize the packaging process, reduce material costs, and increase product safety during transportation, making it a valuable investment for companies looking to optimize their packaging processes.

We’ve improved both the quality and speed of our packaging with this machine. It’s reliable and easy to operate, which makes a huge difference in our daily operations.

Luigi Ferraro ItalyThis foam packaging machine is an excellent investment. It has made our packing process quicker and more efficient while ensuring top-notch protection for our products.

Sophie Wang ChinaOur packaging process has become so much smoother since we started using this machine. It’s easy to maintain and works like a charm every time.

Daniel Martin UKCertificate Of UREXCEED Foam Packaging Machine

UREXCEED Foam Packaging Machine is certified to meet international quality standards, ensuring that it delivers reliable and consistent performance. It is certified under ISO 9001:2015, guaranteeing a robust quality management system throughout the design, production, and service processes. Additionally, it complies with CE standard, demonstrating that it adheres to European safety and environmental regulations. These certifications assure our customers of the machine’s high safety standards, durability, and eco-friendly operation. We also provide full documentation, including material certifications, inspection reports, and traceability records, to give customers full confidence in the quality and compliance of their foam packaging solutions.

A must-have for anyone in the packaging industry. This foam packaging machine provides excellent foam consistency and has significantly reduced our packaging time.

David Hwang South Korea