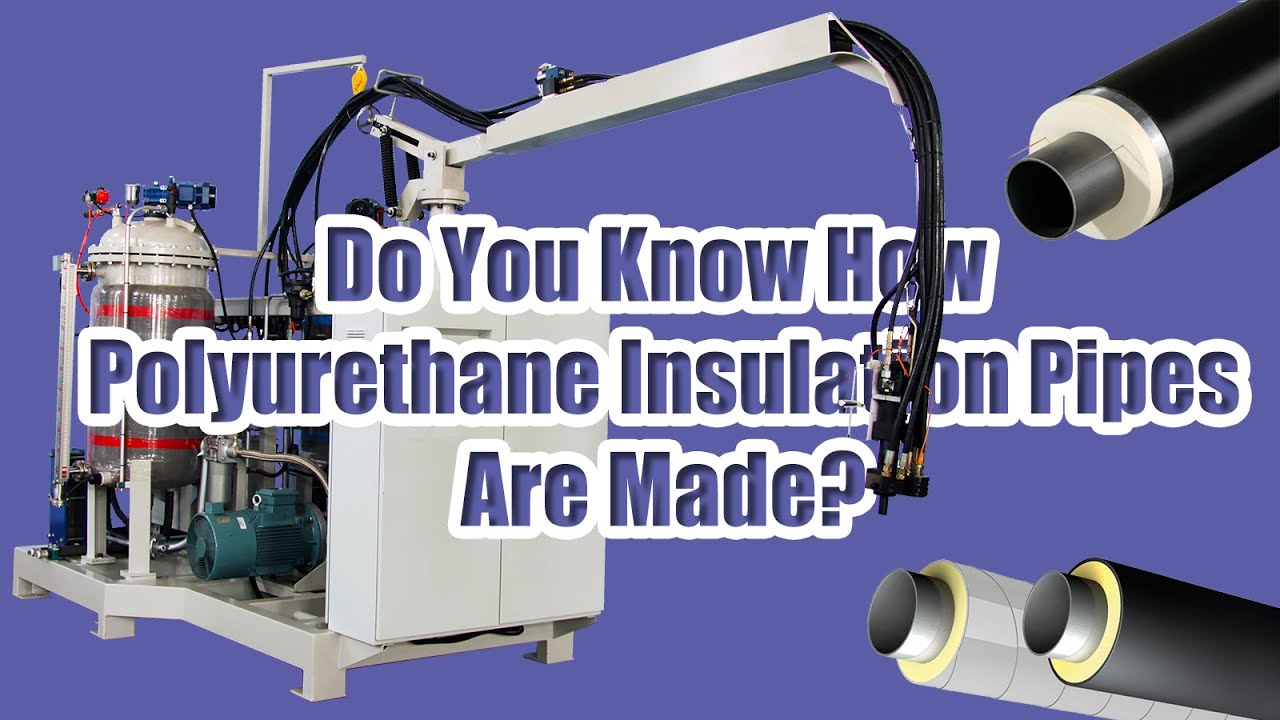

High Pressure Polyurethane Foaming Machine

- The production cycle is as short as 35 days to complete production

- Installation-free design, ready to use right out of the box, saving installation time and cost.

- Designed for easy maintenance, reduced downtime and increased productivity.

- Diversified configurations, three configurations: high, medium and low to meet all customer needs

Classification Of UREXCEED High Pressure PU Foaming Machine

UREXCEED high pressure polyurethane foaming machine is a device used for chemical reaction processes such as polyurethane foaming and pouring, and is widely used in many industries such as automobiles, construction, packaging, etc. According to different application requirements, high pressure polyurethane foaming machines can be divided into several types: two-component high pressure polyurethane foaming machines are used to mix two raw materials (such as polyether and isocyanate); three-component high pressure foaming machines add a third component to the two-component, usually used to adjust the density; cyclopentane high pressure foaming machines are specially designed for the production of polyurethane using cyclopentane as a foaming agent, and have explosion-proof devices to ensure safety. These different types of high pressure polyurethane foaming machines can meet various production needs and provide efficient, precise and safe production processes.

UREXCEED

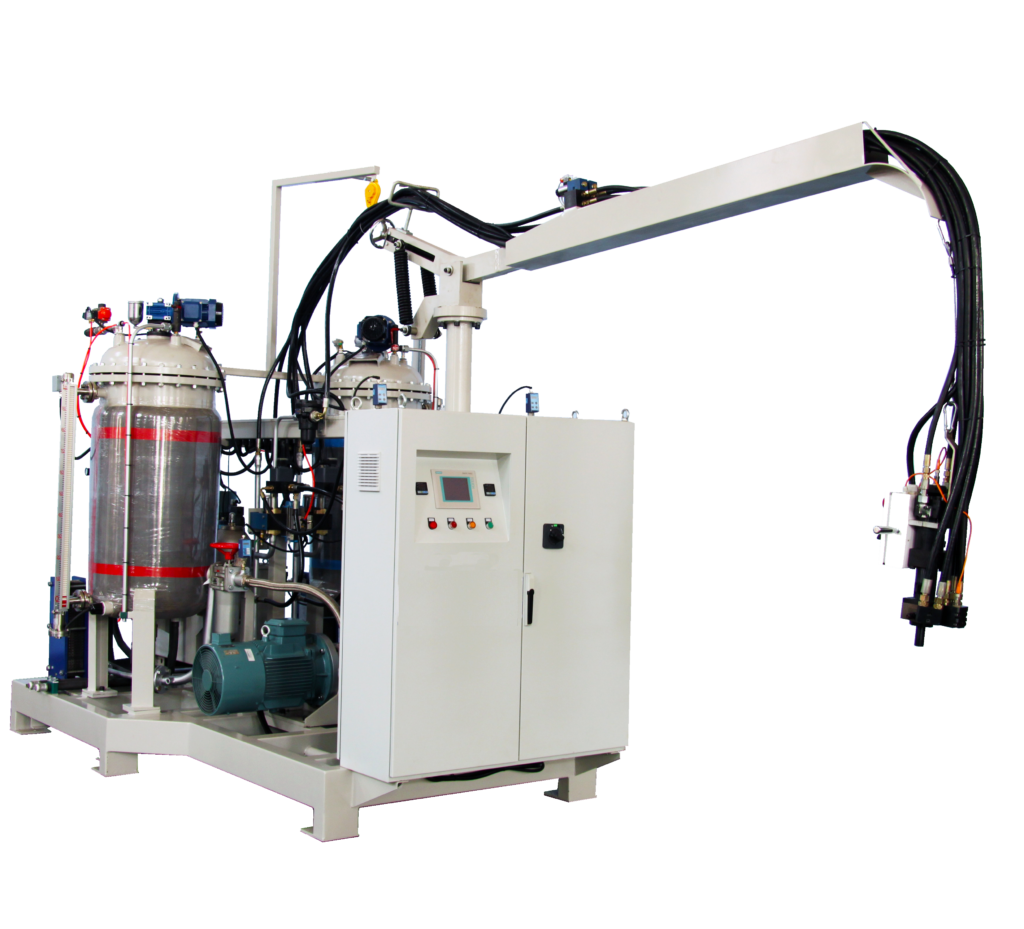

PU Two Component High Pressure Foam Machine

UREXCEED two component high pressure polyurethane foaming machine is primarily designed with two main components: isocyanate and polyol. UREXCEED machine operates by mixing these components under high pressure, resulting in the production of polyurethane foam. It is widely used in applications such as automotive seating, building insulation, and household products. The dual-component system is efficient and straightforward, making it ideal for large-scale production of standard foam materials.

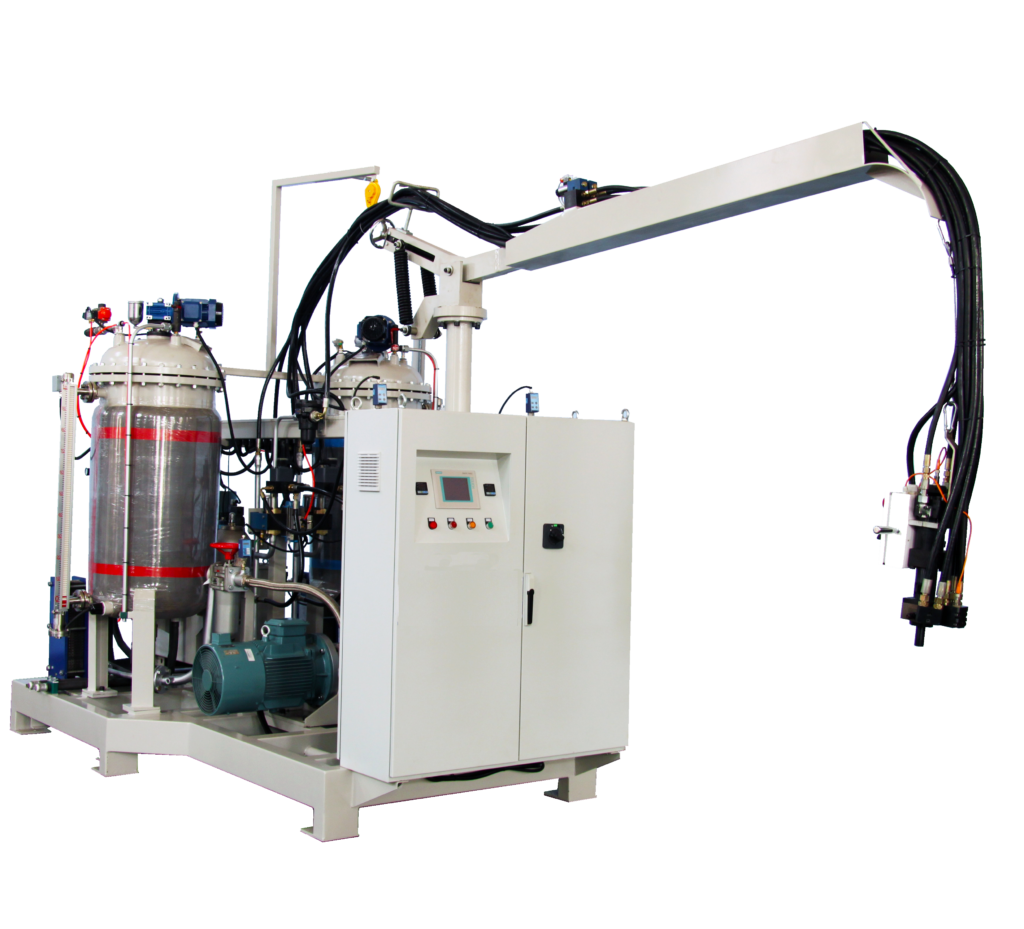

UREXCEED

PU Three Component High Pressure Foam Machine

The UREXCEED three-component high-pressure polyurethane foam injection molding machine is equipped with an additional tank to add a third material. This feature enables the production of foams in different colors and densities to meet specific market needs. By adjusting the formulation of the third component, manufacturers can produce specialized foams with enhanced properties such as flame retardancy or UV protection. This versatility makes this three-component injection molding machine ideal for high-tech applications in the aerospace and medical device sectors.

UREXCEED

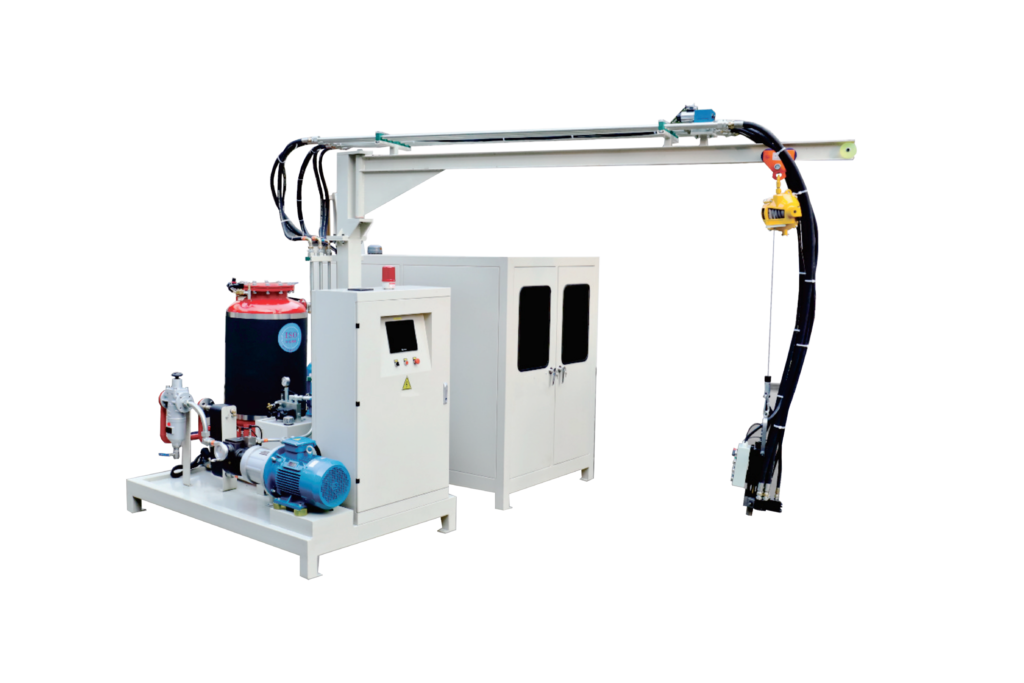

PU Cyclopentane Series High Pressure Foam Machine

UREXCEED cyclopentane series high-pressure machine is specifically designed to handle ring-pentane, a commonly used blowing agent. The entire system is equipped with explosion-proof devices to ensure safety when using volatile substances. The use of ring-pentane allows the final products to be lighter and have excellent elasticity, making it particularly suitable for applications requiring low density and high thermal insulation performance, such as in construction and refrigeration industries. Due to its safety design, the ring-pentane high-pressure machine excels in processing polyurethane foam while meeting high safety and performance requirements.

| ltem | Technical Parameter |

| Foam application | PU |

| Mixing ratio range | 1:3~3:1(adjustable) |

| Iniection time | 0.5~99.99S(correct to 0.01s) |

| Material temperature control error | ±2° |

| Repeated injection accuracy | 1% |

| Tank volume | 250L |

Want to know more about specification of high pressure pu foam injection machine?

Mixing Head Of High Pressure PU Foam Machine

Urexceed’s mixing head is made of high-strength material with a service life of more than 1.5 million times. Impact mixing and high-pressure injection technology are used to ensure that the raw materials are mixed evenly. The self-cleaning function of the machine ensures no residue and easy cleaning and maintenance.

Filter Of High Pressure PU Foam Machine

The filters are specifically designed to effectively remove impurities and particles that may arise during the production process. Through a sophisticated filtration system, the raw materials entering the mixing chamber are ensured to be pure and impurities are prevented from affecting the foaming process and final product quality.

Precision Metering System Of High Pressure PU Foam Machine

UREXCEED equipment is equipped with high-precision metering pumps, which can accurately control the flow of each component, ensure the precise proportion of foaming materials, and reduce quality fluctuations caused by proportion errors. All equipment uses international brand accessories such as Siemens, Rexroth, and Galanz.

PLC Control System Of High Pressure PU Foam Machine

Adopting advanced PLC control system, automatic cleaning and air flushing, it has stable performance and strong operability. It will automatically identify, diagnose and alarm when abnormal, and display abnormal factors, etc.;

Relief Valve Of High Pressure PU Foam Machine

Urexeed’s high-pressure foaming machine relief valve is manufactured with high-precision engineering and features fast response, high-pressure resistance, and corrosion resistance. Its superior sealing performance minimizes leakage risks, enhancing both safety and reliability. Additionally, the valve is designed with adjustable pressure settings, allowing users to customize pressure thresholds based on specific foaming applications for improved production efficiency.

Contact us for full range quote

UREXCEED machines are 30% cheaper than european machine

Working Principle Of UREXCEED High Pressure PU Foaming Machine

The working principle of UREXCEED high-pressure foaming machine involves precisely mixing different raw materials under high pressure and injecting them into molds to form polyurethane foam or other chemical products. The process works as follows:

01 Material Supply

UREXCEED high pressure pu machine is typically equipped with multiple storage tanks for different raw materials (such as polyols, isocyanates, catalysts, etc.). These materials are delivered to the mixing head through pumps or pipelines.

02 Precise Metering and Mixing

UREXCEED machine uses high-precision pumps to deliver each component to the mixing head in exact proportions and pressure. At the mixing head, the raw materials are blended at high speed to ensure complete mixing and avoid air bubbles or uneven blending.

03 High-Pressure Injection

After mixing, the raw materials are quickly injected into the mold through a high-pressure injection system, and the raw materials react and foam quickly to form uniform polyurethane foam.

04 Curing and Molding

After the polyurethane foaming material is injected into the mold, it begins to cure under high pressure and temperature control conditions, and finally forms the desired product. The curing time and temperature can be adjusted according to the specific product requirements.

Maintenance Of UREXCEED High Pressure PU Foaming Machine

High-pressure polyurethane foaming machines are widely used in insulation, automobile, packaging and other industries. In order to ensure long-term stable operation of the equipment, improve production efficiency, reduce failure rate and extend service life, daily maintenance and care are essential.

Inspect and Adjust the Pressure System

The pressure system in a high pressure machine compresses materials and sends them to the mixing head for foaming, making its condition critical for foam quality and machine stability. Regular inspection and adjustment are essential for maintaining precise operation.

Regular Inspection and Cleaning of the Piping System

The piping system in a high-pressure foam machine is crucial for smooth material flow, but over time, residual materials can accumulate or harden, causing blockages and performance issues. Regular inspection and cleaning are essential for effective maintenance.

The lubrication system in a PU high pressure foam machine is essential for ensuring smooth operation of moving parts. Inadequate lubrication or oil system failure can cause overheating, excessive wear, and potentially severe mechanical breakdowns.

Contact us for high pressure foaming machine repair services

Difference Between High & Low Pressure PU Foaming Machine

The working principle of UREXCEED high-pressure foaming machine involves precisely mixing different raw materials under high pressure and injecting them into molds to form polyurethane foam or other chemical products. The process works as follows:

01 Structure and Principle

- High-pressure machines use pumps to mix and are suitable for large-scale production.

- Low-pressure machines use mechanical stirring, suitable for small to medium-scale production.

02 Mixing Efficiency

- High-pressure machines create uniform foam with fine cell structures.

- Low-pressure machines produce foam with uneven cells.

03 Material Compatibility

- High-pressure machines handle complex, high-viscosity systems.

- Low-pressure machines are better for simpler, low-viscosity materials.

04 Cost

- High-pressure machines have higher upfront costs but lower long-term operating costs.

- Low-pressure machines are cheaper initially but incur higher maintenance costs.

05 Product Quality

- High-pressure machines produce high-quality, consistent foam.

- Low-pressure machines produce foam with less consistency and quality.

06 Applications

- High-Pressure: Automotive, construction insulation, high-end appliances.

- Low-Pressure: Packaging, furniture, toys.

How To Choose Right PU Foam Machine

1. Assessing Production Needs

The first step is to evaluate production requirements. If the target market is high-end and demands superior product performance, such as automotive seats or high-performance insulation materials, high-pressure foaming machines are the best choice. For low-end or large-scale production of simple products, low-pressure machines may suffice.

2. Budget Analysis

High-pressure machines are more suitable for businesses with sufficient capital and long-term operational plans. On the other hand, low-pressure machines are more cost-effective for small businesses or those with budget constraints.

3. Application-Specific Considerations

Each industry has unique requirements. High-pressure machines excel in sectors like automotive, construction, and high-end appliances, where quality and performance are paramount. Low-pressure machines are better suited for packaging, furniture, and low-end consumer goods.

By understanding the key differences between high-pressure and low-pressure foaming machines, businesses can make informed decisions based on their specific production needs, budget, and application scenarios. Whether aiming for high-end precision or cost-effective manufacturing, selecting the right equipment is crucial to achieving operational efficiency and product excellence. As technology continues to advance, both types of machines will evolve to meet the diverse needs of the polyurethane foam industry.

FAQs of UREXCEED High Pressure PU Foam Machine

Yes, the operation of high-pressure foaming machines requires professional training because it involves the control of high-pressure systems and precise proportions. We will provide free training when the machine is delivered and installed

Polyurethane high-pressure foaming machines require regular inspection and maintenance, especially nozzles, seals, pipelines and control systems. It is usually inspected once a month and key components such as seals and nozzles need to be replaced regularly. In addition, the machine failure rate is very low.

Common accessories problems include clogged nozzles, loose seals, pipe leaks, etc. Consumable parts need to be replaced regularly.

Production efficiency depends on the machine configuration and production needs. Usually a high-pressure foaming machine can complete a complete foam injection process in a few minutes. We can customize the automation upon request.

- The relationship between temperature and pressure follows specific physical laws that operators must understand to maintain safe operation

- Advanced control systems like PID controllers offer precise regulation of multiple parameters simultaneously

- Proper valve selection is crucial for effective flow rate management in high-pressure environments

- Regular calibration and maintenance of sensors and control components ensures accurate system performance

- Safety mechanisms must be integrated at every level to prevent catastrophic failures in high-pressure systems

Density and hardness are mainly controlled by adjusting the ratio of components A and B. high pressure polyurethane foam injection machines are generally equipped with precise proportion control systems.

Yes, the equipment can be customized according to customer needs, such as automated process flow (making materials, spraying release agent, opening and closing molds), station switching, formula switching, etc.

The energy consumption of high pressure pu foaming machines is usually related to the production volume and foaming conditions. Modern equipment is often designed with energy efficiency optimization systems that reduce energy consumption.

When cleaning, you need to use special cleaning agents and follow the cleaning cycles and methods recommended by the manufacturer. Regular cleaning of nozzles, pipes and other components will help extend the service life of the equipment. Currently our equipment also supports automatic cleaning of filters.

If you are interested in our high pressure pu foam machine, please contact us immediately

Playlist

Good Review Of UREXCEED High Pressure PU Foam Machine

UREXCEED High Pressure PU Foam Machine has garnered outstanding reviews for its exceptional performance and reliability across various industries. Customers appreciate its ability to produce high-density, uniform foam with minimal waste, making it a cost-effective solution for high-volume production. Users have praised the machine’s precision in managing the high-pressure foaming process, which ensures consistency in foam density and application, critical for products like automotive components, insulation panels, and packaging materials. Many clients have also highlighted its easy integration into existing production lines and its user-friendly interface, which minimizes training time and operational complexity.

This high-pressure machine is perfect for our needs. We’ve seen a noticeable improvement in foam consistency and product quality.

Luca Moretti ItalyGreat machine, works flawlessly. Highly recommend for anyone looking to improve their polyurethane foam production.

David Lee UKThe system is very efficient, with easy-to-follow instructions. It saves us both time and costs in production.

Karl Schmidt GermanyApplication Of UREXCEED PU High Pressure Foam Machine

UREXCEED High Pressure PU Foam Machine is widely used in industries that require precise and efficient polyurethane foam applications, including automotive, construction, packaging, and insulation. This machine is designed to produce high-density foam with exceptional uniformity, offering a reliable solution for molding, insulating, and cushioning applications. It is particularly effective in the automotive industry for manufacturing seat cushions, door panels, and other components that require both lightweight and high-performance properties. In construction, it is used for producing insulation panels, providing energy-efficient solutions for buildings. Additionally, UREXCEED High Pressure PU Foam Machine is ideal for packaging materials, ensuring that products are securely cushioned during transit. Its versatility, coupled with its ability to achieve high pressure and accurate foam ratios, makes it an indispensable tool for businesses seeking optimal foam quality and efficiency.

Automotive

Home Furnishings

Toys

Home Decoration

Footwear

Cold Chain

Related Products Of PU High Pressure Foam Machine

In addition to UREXCEED high pressure pu foaming machine, we also offer a wide range of high-performance polyurethane equipment, including low-pressure foaming machines, dispensing machines, spray machines, elastomer casting machines,air filter gasket machine and more. These machines are widely used across various industries to meet diverse customer production needs. If you’re interested in learning more about our other equipment, feel free to click to explore further. We are happy to provide detailed product information and technical support.

Certificate Of UREXCEED PU Foam Machine

UREXCEED High Pressure PU Foam Machine is certified to meet international standards of quality and safety, ensuring it delivers reliable and consistent performance. It holds ISO 9001:2015 certification for quality management, assuring that all aspects of the design, production, and service processes meet stringent quality control standards. UREXCEED machine also complies with CE and RoHS certifications, ensuring it adheres to European safety and environmental regulations. Additionally, we provide full documentation, including material certifications, inspection reports, and traceability records, offering transparency and confidence in the machine’s compliance with industry standards. These certifications demonstrate our commitment to delivering high-quality, reliable equipment that meets the rigorous demands of the polyurethane foam industry.

We have been using this machine for several months now, and the results are consistently excellent. The quality control is precise, and the machine never fails us.

Maria Gonzalez Spain