Ever looked at a refrigerator’s price tag and wondered where that number comes from? The truth is, manufacturing costs involve much more than meets the eye. In this guide, we’ll break down the real expenses behind refrigerator production and show you how strategic equipment choices can optimize your costs.

Last updated: June 2025 | Reading time: 6 minutes

You’ll discover:

- Material costs that consume 50-60% of your budget (and how to optimize them)

- How production scale can slash per-unit costs by up to 40%

- Why foaming equipment selection makes or breaks your insulation quality

- Labor-saving automation solutions that pay for themselves in <18 months

- UREXCEED’s proven cost-reduction strategies for appliance manufacturers

What’s the True Cost to Make a Refrigerator?

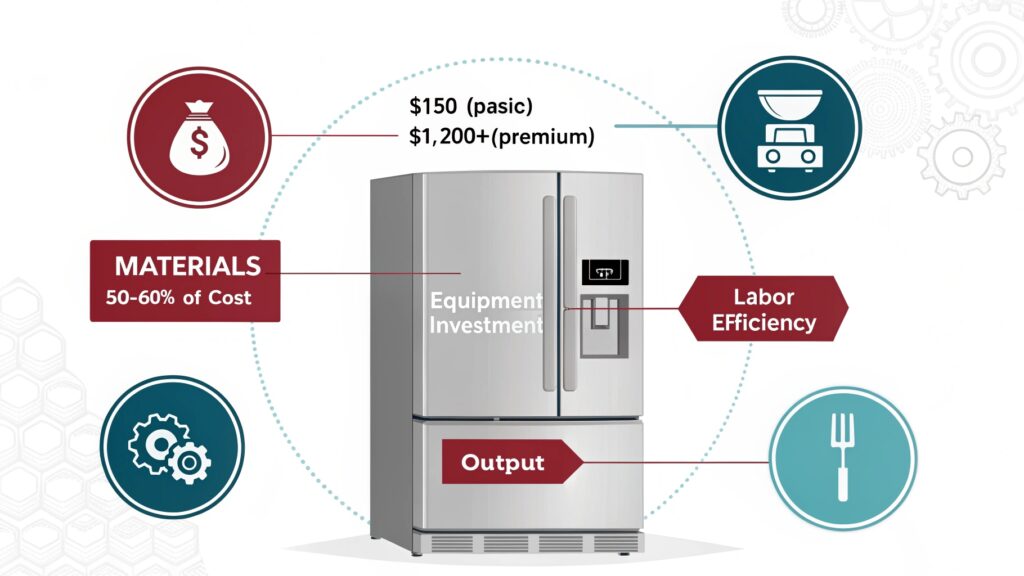

The manufacturing cost ranges from $150 for basic 100L models to $1,200+ for premium 600L smart fridges. But these numbers vary dramatically based on your materials, labor rates, and production methods. The biggest cost drivers are:

- Materials (50-60% of total cost)

- Equipment investments

- Labor efficiency

- Production volume

Here’s what most manufacturers don’t realize: Your equipment choices directly impact 3 of these 4 factors. Modern foaming and assembly systems from UREXCEED can reduce material waste by 15% while doubling output speed compared to outdated lines.

Material Costs: Where Does the Money Go?

| Materials consume the largest portion of your budget. Here’s the 2025 price breakdown for key components: | Component | Cost Range | Smart Saving Tip |

|---|---|---|---|

| Steel Casing | $30-$80 | Use VCM-coated 0.5mm steel for durability at lower cost | |

| PU Foam Insulation | $15-$40 | Invest in precision dispensing equipment to reduce waste | |

| Plastic Components | $20-$60 | Optimize mold design to minimize material use | |

| Compressor | $50-$150 | Balance efficiency rating with lifecycle costs | |

| Seals & Gaskets | $5-$15 | Automated PU dispensing cuts labor costs by 75% |

Pro Tip: Many manufacturers overspend on steel thickness. Our testing shows 0.5mm VCM-coated steel provides optimal durability while saving $12/unit versus 0.7mm alternatives.

Manufacturing Equipment: Cost vs. Value

Your equipment decisions create lasting cost impacts. Modern systems offer:

- Foaming Lines ($200K-$500K): UREXCEED’s automated models complete cycles in 16-30 seconds with ≤380KW power consumption

- Metal Forming ($100K-$300K): Servo-driven bending lines increase precision while reducing scrap rates

- Assembly Systems: Semi-automated lines with 30-second cycle times

- Real-World Example: A mid-size manufacturer reduced unit costs by 22% after upgrading to UREXCEED’s foaming line. The $350K investment paid back in 14 months through higher output and reduced material waste.

The Scale Advantage: How Volume Lowers Costs

| Production volume dramatically affects your bottom line: | Annual Output | Cost/Unit | Key Savings Drivers |

|---|---|---|---|

| 5,000 units | $280 | High manual labor share | |

| 50,000 units | $210 | Better material pricing | |

| 500,000 units | $165 | Full automation justified |

Hidden Opportunity: Implementing UREXCEED’s turnkey solutions helps smaller manufacturers achieve large-scale efficiencies faster.

5 Proven Ways to Reduce Your Costs Now

- Material Optimization: Our engineers can reformulate PU mixes to maintain performance while cutting 8-12% from foam costs

- Automated Dispensing: Eliminate sealant waste with precision PU gasket systems

- Energy Recovery: New foaming lines recapture 40% of process heat

- Modular Design: Standardized components reduce inventory costs

- Preventive Maintenance: Our connected equipment alerts you before issues cause downtime

2025 Refrigerator Manufacturing Trends

The industry is moving toward:

- AI-Optimized Foaming: Machines that automatically adjust mixing ratios for perfect results every time

- Sustainable Materials: Bio-based PU formulations with equal performance at 15% lower cost

- Hybrid Production: Combining high-volume lines with flexible cells for customized models

FAQ: Your Top Cost Questions Answered

How much can automation save me?

Most manufacturers see 25-40% labor cost reductions, with payback in 12-24 months depending on volume.

What’s the minimum viable production scale?

Economical production starts at 10,000 units/year when using UREXCEED’s compact foaming systems.

How do tariffs affect costs?

Our localized supply chain helps clients avoid up to 25% in tariffs through regional sourcing.

The Bottom Line

Understanding refrigerator manufacturing costs helps you make smarter decisions. While materials dominate expenses, strategic equipment investments create lasting savings through:

- Reduced material waste

- Higher output speeds

- Lower labor requirements

- Improved energy efficiency

UREXCEED specializes in helping manufacturers achieve these savings. Our solutions have helped clients reduce unit costs by 18-35% while improving quality.

Next Step: Request your free production line assessment to identify your biggest cost-saving opportunities.

About UREXCEED

With 15 years specializing in refrigeration manufacturing systems, we’ve helped 200+ clients optimize their operations. Our complete solutions include:

- High-efficiency PU foaming equipment

- Custom production line design

- Raw material optimization services

- Ongoing technical support

Contact us now to discuss how we can help reduce your refrigerator manufacturing costs.