Polyurethane high-pressure machines have revolutionized manufacturing processes across multiple sectors due to their precision and efficiency in dispensing polyurethane materials. These specialized machines have gained particular traction in industries where thermal insulation, structural integrity, and customizable material properties are essential to product quality and performance.

Key Takeaways

- The construction and insulation industry relies heavily on high-pressure polyurethane machines for spray foam applications

- Automotive manufacturing uses these machines to produce components like seats, headrests, and specialized parts

- The refrigeration industry depends on polyurethane dispensing equipment for creating efficient thermal insulation in coolers and refrigerators

- High-pressure machines enable furniture makers to create comfortable, durable cushioning and specialized ergonomic products

- Marine and aerospace sectors utilize these machines for lightweight yet durable components that can withstand extreme conditions

1. Understanding Polyurethane High-Pressure Machines

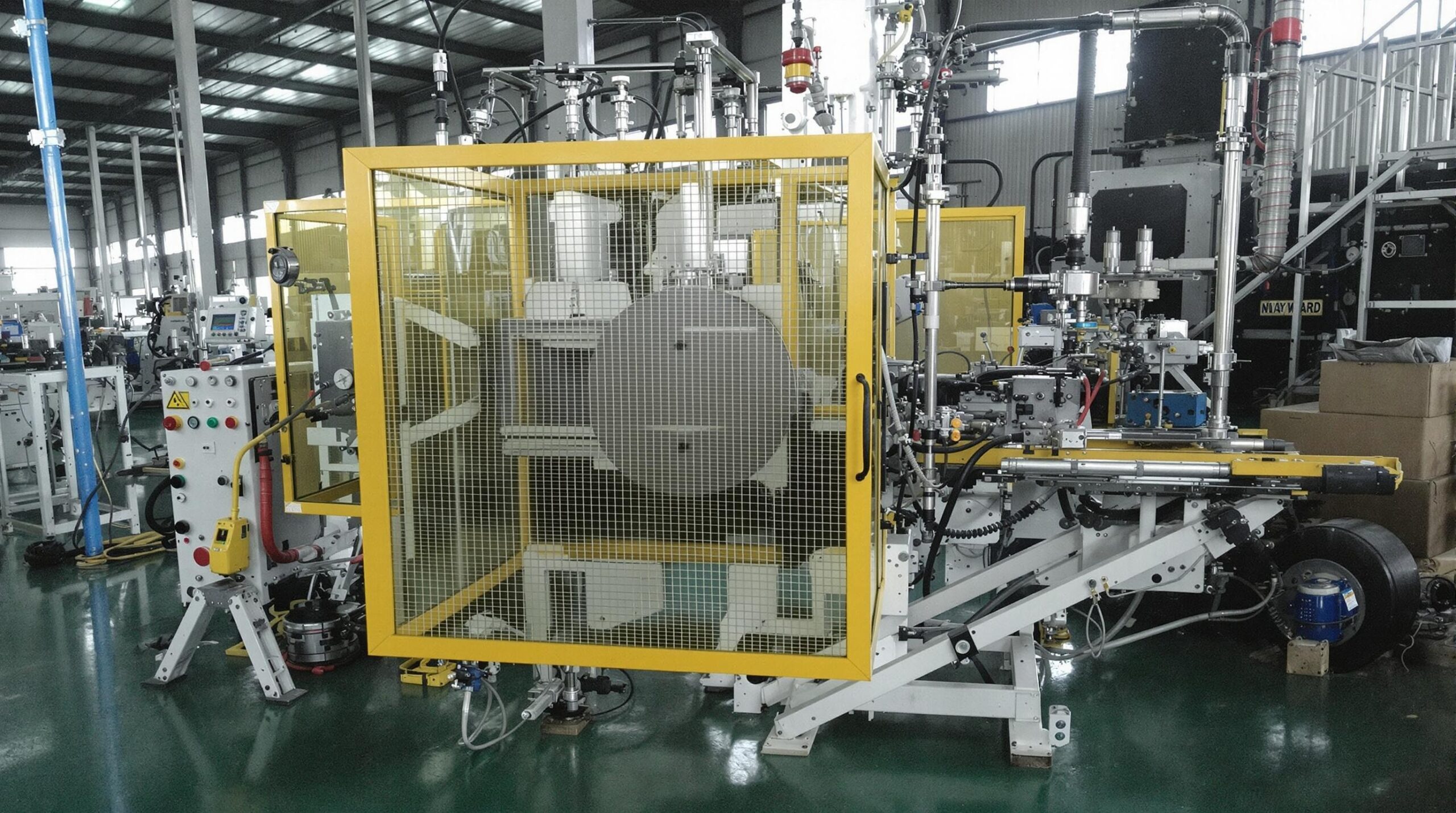

Polyurethane high-pressure machines are specialized equipment designed to mix and dispense two-component polyurethane systems with precision and efficiency. Unlike low-pressure machines, these systems operate at pressures typically ranging from 1,500 to 3,000 psi, allowing for superior mixing of the polyol and isocyanate components that form polyurethane.

The high-pressure technology ensures that the chemical components are thoroughly mixed at the molecular level, resulting in consistent material properties throughout the final product. This level of precision is critical for applications where structural integrity, insulation values, or product quality depends on the uniformity of the polyurethane material.

These machines typically feature advanced control systems that allow operators to adjust mixing ratios, dispensing rates, and other key processing parameters. This flexibility makes high-pressure machines suitable for a wide range of industries and applications where polyurethane's unique properties can be leveraged to create superior products.

3. Construction and Insulation Industry Applications

The construction sector represents one of the largest markets for polyurethane high-pressure equipment, with spray foam insulation being a primary application. These machines enable contractors to apply polyurethane foam to walls, roofs, and foundations, creating seamless thermal barriers that significantly improve building energy efficiency.

High-pressure machines are particularly valuable in this industry because they allow for the rapid application of spray foam over large areas and in hard-to-reach spaces. The high-pressure delivery ensures proper mixing and expansion of the foam, creating the cellular structure needed for optimal insulation performance.

Beyond basic insulation, these machines are used in specialized construction applications such as:

- Roofing systems that provide waterproofing and insulation in one application

- Structural reinforcement for existing buildings

- Air barrier systems that improve building envelope performance

- Sound dampening treatments for commercial and residential structures

- Flotation applications for marine docks and structures

The versatility of high-pressure polyurethane equipment has made it essential technology for modern construction firms looking to improve building performance while reducing installation time compared to traditional insulation methods.

2. Automotive Industry Implementation

Automotive manufacturers have embraced polyurethane high-pressure machines for producing a wide range of vehicle components. The automotive industry values these machines for their ability to create parts with precise densities, dimensions, and physical properties required for today's vehicles.

Seating represents one of the most significant applications, with high-pressure machines used to produce foam cushions for seats, headrests, and armrests. These components must meet strict comfort, safety, and durability standards while maintaining consistent properties across thousands of units.

Beyond seating, automotive applications include:

- Dashboard components and interior trim elements

- Acoustic and thermal insulation within vehicle structures

- Energy-absorbing components for impact protection

- Specialized parts like steering wheel covers and gear shift knobs

The automotive industry's requirements for precision manufacturing make high-pressure polyurethane equipment particularly valuable. These machines allow for exact material formulations and processing conditions that ensure parts meet strict quality and performance specifications while maintaining high production rates.

Refrigeration and Cold Chain Industry

The refrigeration industry relies heavily on polyurethane high-pressure technology to create the thermal insulation critical to refrigerators, freezers, and commercial cold storage units. The superior insulating properties of polyurethane foam make it the material of choice for maintaining low temperatures with minimal energy consumption.

High-pressure machines are particularly valuable in this sector because they create foam with a uniform cell structure that maximizes insulation performance. The precise mixing and dispensing capabilities ensure consistent thermal resistance throughout the insulated cavity, eliminating hot spots that would reduce energy efficiency.

Common refrigeration applications include:

- Residential refrigerator and freezer cabinet insulation

- Commercial refrigeration units for restaurants and retail

- Insulated transport containers for the cold chain logistics sector

- Walk-in coolers and freezers for industrial and commercial use

- Specialized medical refrigeration for pharmaceuticals and biological materials

The refrigeration industry's strict requirements for thermal performance and energy efficiency make high-pressure polyurethane machines indispensable. These systems allow manufacturers to meet increasingly stringent energy regulations while producing reliable products with extended service lives.

Furniture Manufacturing Applications

Furniture manufacturers have long recognized the value of polyurethane foam for creating comfortable, durable seating and bedding products. High-pressure machines allow these manufacturers to produce foam components with specific densities, firmness levels, and recovery properties tailored to different product lines.

Unlike many other applications that use spray foam, furniture often requires molded foam components with precise shapes and dimensions. High-pressure machines excel in this environment, dispensing polyurethane into molds with the exact amount of material needed for proper filling and consistent density.

The furniture industry utilizes these machines for:

- Cushions for sofas, chairs, and other seating

- Mattresses and mattress toppers with varied comfort layers

- Ergonomic office furniture components

- Decorative and functional elements like padded headboards

- Specialized products such as medical furniture and gaming chairs

The ability to fine-tune foam properties makes high-pressure polyurethane equipment particularly valuable for furniture manufacturers who need to create products with specific comfort, support, and durability characteristics to meet consumer expectations.

Marine and Aerospace Industry Usage

Both marine and aerospace industries utilize polyurethane high-pressure machines to create lightweight yet durable components for vessels and aircraft. In these applications, the weight-to-strength ratio of materials is critical, making polyurethane an excellent choice for many structural and functional elements.

In the marine industry, high-pressure machines are used to create flotation foam that provides buoyancy while also offering structural support and insulation. These foams must withstand harsh marine environments including saltwater exposure, temperature fluctuations, and physical stress.

Aerospace applications focus on components where weight savings translate directly to fuel efficiency and performance improvements. Key applications include:

- Thermal and acoustic insulation for aircraft cabins

- Lightweight structural components for interior elements

- Energy-absorbing materials for safety systems

- Specialized composite components where polyurethane provides matrix materials

Both industries benefit from the precise control that high-pressure machines provide over material properties, ensuring that components meet the strict regulatory requirements and performance standards essential for these demanding applications.

Wind Energy Sector Applications

The growing wind energy sector has become an important market for polyurethane high-pressure equipment. Wind turbine manufacturers use these machines to create specialized components that help improve turbine performance, durability, and energy output.

One of the primary applications is the production of core materials for wind turbine blades. These structural cores provide the necessary rigidity while maintaining the lightweight properties essential for efficient energy generation. High-pressure machines ensure uniform material distribution and consistent physical properties throughout these large components.

Other wind energy applications include:

- Insulation systems for nacelle components

- Vibration dampening elements to reduce mechanical stress

- Weather sealing systems that protect sensitive components

- Specialized coatings and surfacing materials for blade protection

As turbines grow larger and are deployed in more challenging environments, the material performance requirements become increasingly demanding. High-pressure polyurethane systems provide the manufacturing precision needed to meet these specifications while maintaining production efficiency.

Packaging Industry Applications

The packaging sector relies on polyurethane high-pressure machines to create protective packaging solutions for fragile or valuable items. Custom-molded polyurethane foam provides superior protection against impacts, vibration, and other transportation hazards compared to many traditional packaging materials.

High-pressure equipment allows packaging manufacturers to create foam that precisely conforms to product contours, providing maximum protection with minimum material use. This precision is particularly valuable for high-value electronics, medical devices, and industrial equipment that requires secure transport.

Common packaging applications include:

- Custom-molded protective inserts for shipping cases

- Foam-in-place packaging systems for varied product shapes

- Protective padding for consumer electronics and delicate goods

- Specialty packaging for scientific instruments and calibrated equipment

- Reusable protective cases with custom interior foam

The packaging industry values high-pressure polyurethane machines for their ability to create consistent, reliable protection that can be customized to specific product requirements, reducing damage rates while optimizing material usage.

Medical and Healthcare Equipment

The medical and healthcare sectors utilize polyurethane high-pressure machines for creating specialized equipment and components that meet stringent healthcare standards. The biocompatibility and customizable properties of polyurethane make it ideal for many medical applications.

Patient support surfaces represent a significant application, with high-pressure machines used to create pressure-relieving foam for hospital beds, operating tables, and rehabilitation equipment. These surfaces must provide specific support characteristics to prevent pressure injuries while being cleanable and durable in healthcare environments.

Additional medical applications include:

- Orthopedic supports and positioning devices

- Prosthetic components that combine comfort and function

- Laboratory equipment insulation and protective elements

- Specialized packaging for sensitive medical devices and supplies

- Comfort elements for mobility devices like wheelchairs

The medical industry's strict regulatory requirements make high-pressure polyurethane machines particularly valuable, as they provide the manufacturing precision and consistency needed to meet healthcare standards while allowing for customization to address specific patient needs.

Sports and Recreation Equipment

The sports and recreation industry has adopted polyurethane high-pressure technology to create performance equipment that enhances athletic capabilities and improves safety. The customizable density, firmness, and resilience of polyurethane foam make it ideal for many sporting applications.

Protective equipment represents a major application area, with high-pressure machines used to create impact-absorbing padding for helmets, body protectors, and training facilities. These materials must provide effective protection while maintaining comfort and flexibility for athletes.

The range of sports equipment applications includes:

- Gymnasium flooring and mats for training and competition

- Padding for football, hockey, and other contact sports equipment

- Specialized footwear components for athletic performance

- Water sports equipment including surfboards and paddleboards

- Training aids with customized support and resistance properties

High-pressure polyurethane equipment allows sports manufacturers to create products with precise performance characteristics that help athletes achieve their potential while reducing injury risks through optimized impact absorption and support.

Future Trends in Polyurethane High-Pressure Machine Applications

The market for polyurethane high-pressure machines continues to expand as new applications emerge across various industries. Several trends are shaping the future of this technology and its industrial applications.

Sustainability has become a major focus, with manufacturers developing machines capable of processing bio-based polyurethanes derived from renewable resources. These systems maintain the precision and performance of traditional high-pressure machines while supporting more environmentally responsible material formulations.

Other emerging trends include:

- Integration with digital manufacturing and Industry 4.0 technologies

- Development of smaller, more efficient machines for specialized applications

- Advanced control systems that optimize material usage and reduce waste

- Adaptation to new polyurethane formulations with enhanced properties

- Increased focus on energy efficiency in machine design and operation

As manufacturing continues to evolve, polyurethane high-pressure machines are likely to find applications in even more industries, driven by the versatility and performance advantages that these systems offer compared to alternative material processing technologies.

Frequently Asked Questions

What is the difference between high-pressure and low-pressure polyurethane machines?

High-pressure polyurethane machines operate at pressures typically between 1,500-3,000 psi, while low-pressure machines work below 600 psi. This pressure difference creates superior component mixing in high-pressure systems, resulting in more consistent material properties and making them suitable for applications requiring precision and high-performance materials.

How much does a polyurethane high-pressure machine cost?

Polyurethane high-pressure machines vary widely in cost depending on capacity, features, and capabilities. Basic industrial systems start around $50,000, while advanced machines with high output capabilities and specialized features can exceed $250,000. Many manufacturers also offer rental or leasing options for project-specific needs.

What maintenance is required for polyurethane high-pressure equipment?

Regular maintenance includes daily cleaning of mix chambers and dispensing components, periodic inspection and replacement of seals and filters, calibration of pressure and flow systems, and thorough cleaning when changing materials. Proper maintenance extends equipment life and ensures consistent product quality.

Can high-pressure polyurethane machines work with all types of polyurethane formulations?

While high-pressure machines can process many polyurethane formulations, they require materials specifically designed for high-pressure application with appropriate viscosity ranges and reaction profiles. Some specialty formulations may need specific machine configurations or processing parameters to achieve optimal results.

What safety considerations are important when operating polyurethane high-pressure equipment?

Safety considerations include proper personal protective equipment (respiratory protection, eye protection, and chemical-resistant clothing), adequate ventilation, pressure safety systems, emergency shutdown procedures, and comprehensive operator training. Always follow manufacturer guidelines and safety data sheets for the specific materials being processed.