In the refrigerator production process, the quality of polyurethane foaming is directly related to the thermal insulation performance and energy level of the product. When problems such as poor foaming, uneven foam structure or insufficient filling occur, they are often caused by omissions in process control or equipment parameters. In response to this challenge, the following systematically sorts out the optimization path from the four major links of raw material mixing, mold positioning, curing conditions and key parameter monitoring.

1. Raw material mixing and pouring control: stable pressure is the key

The use of a high-pressure foaming machine (working pressure 150–200 bar) can achieve molecular-level mixing of isocyanate and polyol, forming more fine-structured bubbles and improving thermal insulation performance (Source: Cannon Afros technical information, 2023).

During the pouring process, it is important to control the pressure fluctuation of the gun tip. It is recommended to control it within ±5% to ensure uniform foaming and avoid quality defects such as shrinkage (foam collapse) or delamination (stratification).

Recommended Practice:

- Choose a high pressure press with a dynamic pressure compensation system;

- Set up a real-time pressure sensor feedback loop;

- Avoid direct foaming during cold start and ensure that the material is preheated evenly.

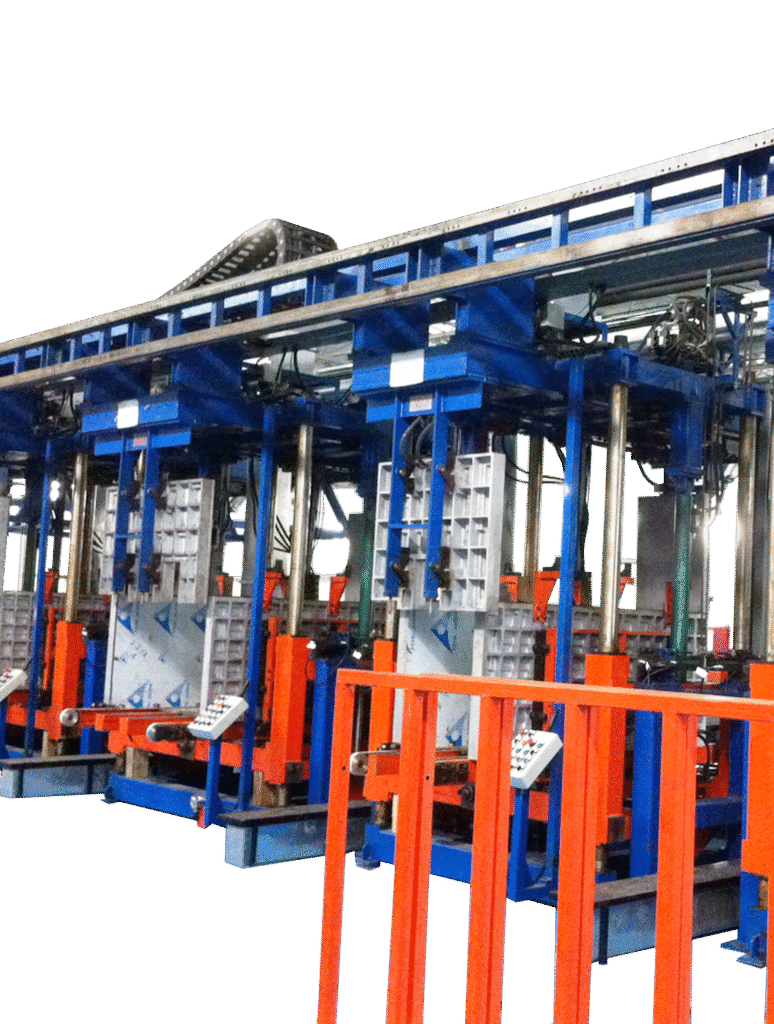

2. Mold positioning and mold clamping accuracy: reduce human errors

Slight misalignment during mold closing may also lead to foam leakage or filling deviation. The pneumatic mold frame system can realize automatic mold closing with a positioning accuracy of up to ±0.5mm.

Some advanced production lines have introduced barcode recognition systems, which allow molds to automatically match box model parameters, reduce worker intervention, and significantly reduce the defect rate (Source: Haier 2024 Smart Factory White Paper).

Recommended equipment configuration:

- Pneumatic clamping system;

- Barcode or RFID automatic identification control system;

- Mold frame temperature control device (preheating the mold to improve foam adhesion).

3. Optimization of curing reaction conditions: dual control of temperature and time

The curing of polyurethane foam is an exothermic reaction process, and precise control of temperature and time is crucial to the foam structure.

It is recommended to stabilize the curing temperature between 100-120°C and control the curing time between 5-8 minutes. Within this range, the foam volume can expand 20-30 times and fully fill the refrigerator body interlayer (data source: PU Europe Technical Manual, 2022).

After curing, a “vacuum bubble breaking” treatment should be carried out to remove residual bubbles generated during the reaction process and enhance the density of the foam.

4. Real-time monitoring of key parameters: ensuring foam consistency

Accurate raw material metering is the basis for stable foam quality. At present, advanced equipment has generally adopted plunger metering pumps, which have high accuracy and small fluctuations.

The control range of foaming density is usually between 30-60 kg/m³, and different models of refrigerators can adjust the ratio according to the insulation requirements. The commonly used raw material ratio is isocyanate: polyol = 1:1 to 3:1 (Source: Covestro Raw Material Manual, 2023).

Recommended monitoring systems:

- Online density monitoring device;

- Automatic ratio correction system;

- Data cloud platform record analysis.

Summary suggestions:

If your refrigerator production line has problems such as frequent foaming defects, low energy efficiency level, and high manual errors, it is recommended to start from the following directions:

- Upgraded high-pressure foaming system with dynamic pressure control;

- Introduced barcode recognition + automatic mold frame clamping technology;

- Accurately control curing temperature and time to optimize foaming expansion ratio;

- Adopt high-precision proportioning pump and real-time density monitoring system.

Through the dual-wheel drive of process refinement and equipment upgrade, the overall foaming defect rate can be controlled below 2%, achieving high thermal insulation and high consistency refrigeration products.

If you need a customized polyurethane foaming solution for refrigerators, we can provide a complete equipment selection and process configuration service. Welcome to consult.