Low Pressure Polyurethane Foaming Machine

- The production cycle is as short as 25 days to complete production

- Small footprint and easy to transport

- Customization options available to meet customer specific needs

- High quality, no leakage, no noise, guaranteed to be used for 10+ years, 3 years warranty

- One-stop solution equipped with all auxiliary equipment including air compressors and chillers, etc.

Classification Of UREXCEED Low Pressure Polyurethane Foaming Machine

UREXCEED low pressure PU foam machine is a kind of equipment used to mix and pour polyurethane foam materials at relatively low injection pressures, typically less than 50 bar (725 psi). Low pressure PU foam injection machines are widely used for small-batch production, precise control of the foaming process, and applications where the foaming speed is less critical, such as toys, interior decoration, automotive parts, furniture production, etc.. Compared to PU high pressure foam machines, PU low pressure foaming machines are ideal for applications requiring gentler reactions or lower-density foams, such as flexible foams or low-density products.

The advantages of UREXCEED low pressure pu foam machines lie in their flexibility and energy efficiency, making them especially suitable for small-batch production or custom foaming products. Compared to PU high pressure foaming machines, low pressure pu foaming machines are cost-effective because of lower initial investment. Due to lower operating pressures, low pressure pu machines have less wear and tear, which make machine maintenance is more easier. Low pressure polyurethane foam injection machines offer more stable control, allowing for precise adjustments when specific requirements for foaming rate, foam quality, or foam density are needed.

UREXCEED also has different models of low pressure pu machines to meet the production needs of different customers.

UREXCEED

PU Two Component Low Pressure Foam Machine

UREXCEED two-component pu low pressure foaming machine produces high-quality polyurethane foam by mixing raw materials in precise proportions. UREXCEED two-component low pressure foaming machines are widely used in the furniture, construction and automotive industries, and are especially suitable for scenarios that require simple operation and efficient production. Its main advantages include low equipment investment, ease of operation and suitability for small batch production.

UREXCEED

PU Three Component Low Pressure Foam Machine

UREXCEED three-component low pressure foam machine adds a third component (e.g., additives or pigments) to the traditional two-component system, enabling more versatile formulations. Its advanced metering and mixing system supports the production of foam products with different colors or densities, making it perfect for applications such as automotive interiors, specialty insulation materials, and other customized solutions. This machine enhances production flexibility and product diversity.

Item | Technical parameter |

Foam application | Rigid foam/Flexible foam |

Injection output | 500-2000g/s |

Mixing ration range | 100:50~150 |

mixing head | 2800-5000rpm, forced dynamic mixing |

Tank volume | 250L |

Weight | 2000Kg |

Want to know more about specification of low pressure pu foam injection machine?

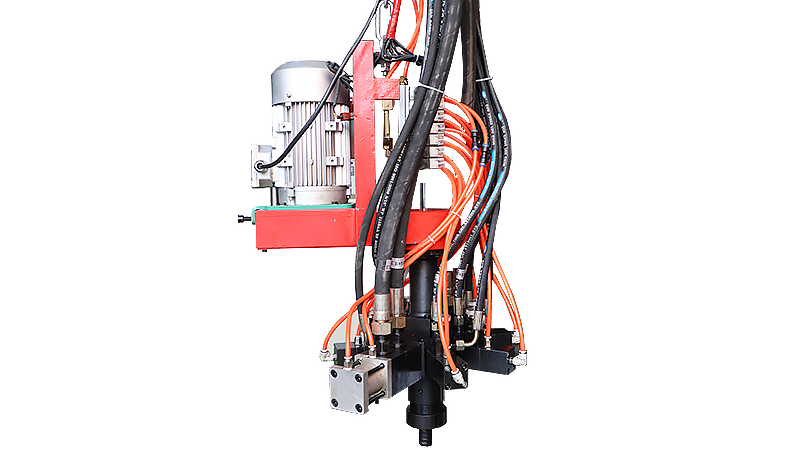

Mixing Head Of Low Pressure PU Foam Machine

Efficient mixing: Use twin-screw or static mixer design to ensure that components A and B are fully mixed before entering the foaming chamber to avoid uneven foam.

Replaceable design: The machine head is designed to be detachable for easy cleaning and replacement, reducing maintenance costs and downtime.

PLC Control System Of Low Pressure PU Foam Machine

Multi-function control: The high-end PLC system can monitor and control the mixing, temperature and pressure of the three components at the same time, supporting complex formula management.

Data recording: The system supports data recording and analysis to help users optimize the production process and improve product quality.

Precision Metering System Of Low Pressure PU Foam Machine

High-precision measurement: Through precise mechanical design and electronic control, accurate control of each delivery volume is achieved to ensure the consistency of the mixing ratio.

Corrosion resistance: The pump body is made of corrosion-resistant materials, which can adapt to different types of raw materials and extend its service life.

Flexible adjustment: Users can easily adjust flow settings according to production needs to meet the requirements of different products.

Working Principle Of UREXCEED Low Presssure PU Foaming Machine

The working principle of low-pressure pu foam machine involves precisely mixing raw materials and injecting them into molds under low pressure, typically used in polyurethane foaming, casting, and other production processes. Compared to high-pressure machines, low-pressure pu foaming machines are often used for applications that require gentler foaming reactions or lower pressures. The process is as follows:

01 Material Supply

UREXCEED low-pressure machine is equipped with multiple storage tanks for different raw materials, such as polyols, isocyanates, and other additives. These materials are delivered to the mixing head through pumps or pipelines.

02 Material Mixing

The low-pressure pump delivers each component to the mixing head at precise ratios and pressures. The materials are thoroughly mixed inside the mixing head to ensure uniform blending, resulting in a stable foaming process.

03 Low-Pressure Injection

After mixing, the material is injected into the mold under low pressure. Low-pressure injection helps minimize air bubbles and uneven mixing, making it ideal for applications where foaming speed is not as critical.

04 Curing and Molding

UREXCEED polyurethane material injected into the mold undergoes foaming and curing at low pressure. The curing time can be adjusted based on production requirements to ensure the desired product shape and performance.

FAQs Of UREXCEED Low Pressure PU Foam Machine

Yes, a static mixer is a device that continuously mixes fluid materials without moving parts. Typically the fluids to be mixed are liquids, but static mixers can also be used to mix gas streams, disperse gases into liquids, or mix immiscible liquids. The energy required for mixing comes from the pressure loss as the fluid flows through the static mixer. One design of static mixer is the plate mixer, another common equipment type consisting of mixer elements contained in a cylindrical or square housing.

It can be increased, but it is recommended not to add it because it is easy for dust to enter, and electronic components can work at a temperature of 90-120 degrees.

Yes, low-pressure pu foaming machines are ideal for large-scale production, especially in cost-sensitive applications that require high throughput. They can provide stable production efficiency and are suitable for continuous production.

PU low-pressure foaming machines can usually handle a larger amount of raw materials in each foaming process and have higher production efficiency. The specific output of the equipment depends on the machine configuration and production conditions.

The operation of the low-pressure pu foaming machine is relatively simple and suitable for beginners and ordinary operators. Most equipment is equipped with automated control systems, making operation more intuitive and reducing the possibility of human error.

The density adjustment is mainly controlled by changing the proportion of components A and B. Low-pressure pu foaming machines are usually equipped with proportional control systems to ensure that foams of different densities can be accurately produced.

The maintenance requirements of low-pressure pu foaming machines are relatively simple. Major maintenance tasks include regular cleaning of sprinkler heads, pipes and seals. The machine’s lubrication system and transmission system require regular inspection and maintenance.

Yes, the pu low-pressure foaming machine can be customized according to customer needs, such as adding barrels of different capacities, spray guns or changing pipeline configurations to suit specific production needs.

Low-pressure pu foam machines have relatively low energy consumption and are suitable for mass production, but the specific energy consumption also depends on parameters such as temperature and pressure during the production process.

Equipment service life can be extended through regular maintenance, cleaning and replacement of wearing parts. Ensuring that excessive pressure and temperature do not occur during operation are also important measures to protect equipment.

If you are interested in our low pressure pu foam machine, please contact us immediately

Playlist

Good Review Of UREXCEED Low Pressure PU Foam Machine

UREXCEED Low Pressure PU Foam Machine has received positive feedback from customers for its reliability, efficiency, and ease of use. Many users have praised its ability to produce high-quality foam with low material waste, making it a cost-effective solution for a wide range of industries. Customers particularly appreciate its low-pressure operation, which allows for greater flexibility in foam production while maintaining consistent density and quality. In addition, the machine’s user-friendly interface and easy setup have been highlighted as major advantages, ensuring quick integration into existing production lines with minimal downtime. UREXCEED Low Pressure PU Foam Machine has proven to be an indispensable tool for companies in automotive, packaging, and construction industries, offering an affordable yet highly efficient solution for foam production.

We’ve significantly reduced waste and improved production speed thanks to this low-pressure machine. Highly recommended.

Carlos Gomez SpainFantastic equipment. It has revolutionized our low-pressure foaming process, delivering consistent, high-quality results.

Edward Brown UKWe couldn’t be more pleased with this machine. It’s easy to use, and maintenance is a breeze. Our production efficiency has soared.

Sebastian Müller SwitzerlandApplication Of UREXCEED Low Pressure Foam Machine

UREXCEED Low Pressure PU Foam Machine is designed to provide cost-effective and efficient solutions for producing polyurethane foam in a variety of applications, including insulation, packaging, automotive, and construction. This machine operates at a lower pressure compared to high-pressure models, making it ideal for applications where precise control over foam density and material usage is essential. In the automotive industry, it is used for manufacturing components like door panels and dashboards that require lightweight, durable foam. In the construction industry, it is widely utilized for producing insulating foams for walls, roofs, and pipes, ensuring energy efficiency and temperature control. Additionally, UREXCEED Low Pressure PU Foam Machine is perfect for producing custom foam packaging, offering superior protection for fragile items during shipping. With its versatile capabilities, the Low Pressure PU Foam Machine is a trusted choice for businesses looking for a reliable and efficient solution to their foam production needs.

Certificate Of UREXCEED Foam Machine

UREXCEED Low Pressure PU Foam Machine is certified to meet the highest international standards, ensuring consistent quality and compliance with industry regulations. It is certified under ISO 9001:2015 for quality management, ensuring a stringent approach to every step of the design, production, and service processes. The machine also holds CE and RoHS certifications, guaranteeing that it meets European safety, environmental, and health requirements. Additionally, UREXCEED provide complete documentation, including material certifications, inspection reports, and batch traceability records, ensuring transparency and confidence in the machine’s performance and compliance. With these certifications, UREXCEED Low Pressure PU Foam Machine is a trusted, high-quality solution for businesses looking to meet global standards while optimizing their foam production processes.

The machine is simple to operate, and the results are perfect every time. It's been an excellent investment for our business.

Anna Fischer Germany