PU Machines Manufacturing on Demand for the Mining Industry

The mining industry is one of the important pillars of the global economy, covering the exploration, mining, processing and sales of various resources, involving metal mines, non-metallic mines, coal and energy minerals. Due to its superior mechanical properties, wear resistance, corrosion resistance and elasticity, polyurethane is widely used in mining equipment, mineral processing, transportation and mine protection.

Polyurethane for mining is different from conventional polyurethane materials. We generally call it polyurethane elastomer. It is more wear-resistant and corrosion-resistant than ordinary polyurethane materials. For this special polyurethane, UREXCEED also has a matching polyurethane elastomer casting machine, which can meet all customer needs in the production of elastomer products.

The Prospects of Polyurethane in the Mining Industry

In order to better understand the application prospects of polyurethane in the mining industry, we can conduct data analysis from aspects such as market size, growth rate, and competitive landscape, and comprehensively evaluate the market potential of polyurethane based on actual market trends and consumer demand.

The Distribution of Different Insulation Materials in the Mining Industry

Property | Polyurethane (PU) | Rubber | Steel | Polyethylene (PE) | Composite Materials |

Density (g/cm³) | 1.1 – 1.3 | 1.1 – 1.4 | 7.8 – 8.1 | 0.91 – 0.96 | 1.3 – 2.0 |

Tensile Strength (MPa) | 40 – 50 | 10 – 25 | 250 – 1000 | 25 – 50 | 100 – 200 |

Elongation at Break (%) | 500 – 800% | 300 – 500% | 10 – 25% | 300 – 800% | 5 – 10% |

Hardness (Shore A) | 60 – 95 | 30 – 90 | N/A | 60 – 80 | N/A |

Abrasion Resistance | Excellent | Good to excellent (depending on type) | Low (unless coated) | Moderate | Excellent |

Impact Resistance | High, excellent rebound | Moderate to high | Very low (can dent or crack) | Low | High |

Chemical Resistance | Excellent, resistant to oils, acids, solvents | Poor to good (depends on type) | Excellent, resistant to most chemicals | Good, resistant to many chemicals | Excellent (depends on resin) |

Temperature Resistance | -40°C to 80°C | -40°C to 100°C | 300°C+ | -50°C to 80°C | -40°C to 150°C |

Flexibility | High, excellent for shaping and molding | High, flexible, can deform under pressure | Rigid and inflexible | Moderate to high | Moderate to high |

Fatigue Resistance | Excellent | Moderate to high | Poor | Moderate | High |

Cost | Moderate to high | Low to moderate | High | Low to moderate | Moderate to high |

Wear Resistance | Excellent | Moderate to high | Very low (unless treated) | Moderate | Excellent |

Applications in Mining | Linings, screens, hoses, belts, wear-resistant parts | Conveyor belts, seals, gaskets, protective wear | Equipment parts, structural components | Chutes, hoppers, liners, piping | High-stress applications, wear parts, liners, reinforcement |

Advantages Of UREXCEED In The Mining Industry

We have a professional team and advanced equipment to meet customers' different needs. Our polyurethane molds are made of high-quality materials to ensure stable product quality and strong durability. We can also design molds of different shapes and sizes according to customer requirements to meet the production needs of different products.

In addition to mold design and manufacturing, we also provide design and manufacturing services for PU machinery and production lines. With our rich experience, we can help customers improve production efficiency, reduce costs, and enhance product quality. Our machines and production lines use advanced technology, are easy to operate, and easy to maintain.

If you are looking for solutions for polyurethane molds, machinery, and production lines in the mining industry, please contact UREXCEED. We will provide you with high-quality products and services to help you achieve your production goals and increase competitiveness.

Urexceed's partners in the mining industry are diverse and of varying sizes.

No matter you are Mining companies, Energy exploration companies, Mining machinery manufacturing companies, Automation technology companies, Mineral smelting companies, Mine car manufacturing companies or not, you can contact us for more information of Mining Industry.

Polyurethane Mixing Machine For

Mining Applications

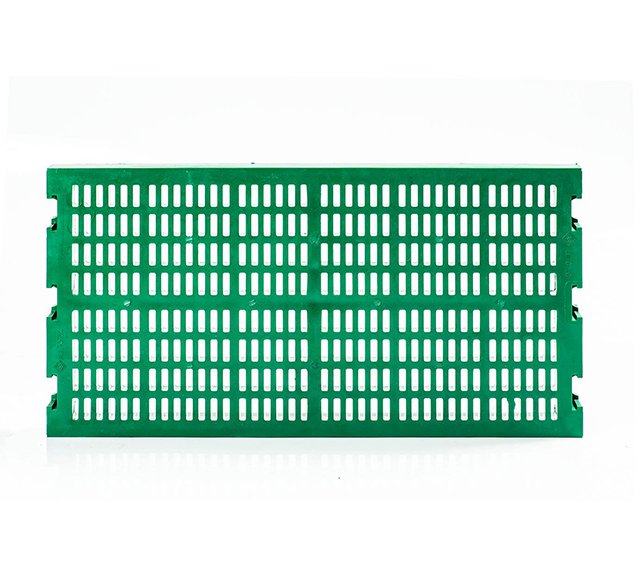

Polyurethane Sieve Screen Making Machine Provided

Polyurethane screens are wear-resistant and highly elastic, and can withstand the impact and abrasion of ores and other hard materials. Compared with traditional metal screens, polyurethane screens have a longer service life and are less prone to clogging, making them suitable for screening operations of various ores and particles.

UREXCEED polyurethane elastomer equipment is specially designed for polyurethane screen production. Our equipment can process a wide range of polyurethane elastomers, including cast, thermoplastic, cast rigid foam elastomers and other materials, covering different hardness ranges and physical property requirements.

Polyurethane Scraper Blades Production Solution

Polyurethane scrapers are widely used in conveyor belt systems for ore and coal to remove ore residues from conveyor belts and ensure efficient operation of conveyor belts. Due to the elasticity and wear resistance of polyurethane materials, it can protect conveyor belts from wear and damage while scraping off residues.

UREXCEED polyurethane elastomer casting machine can be used to produce polyurethane scrapers. Our polyurethane elastomer injection grouting equipment is equipped with advanced control systems such as PLC (Programmable Logic Controller), which can achieve fully automated operation, including proportioning, mixing, injection and cleaning. It can be customized according to customer needs. If you want to produce high-quality polyurethane scrapers, please contact us, we can provide a full set of customized production solutions.

OEM&ODM Forklift Wheels Manufacturing

Polyurethane is a high-performance material widely used in forklift wheel manufacturing. Its excellent properties make it an ideal choice for many industrial applications. Polyurethane has extremely high wear resistance, which is suitable for forklift wheels in industrial environments where they are in long-term contact with rough ground or subjected to high-frequency rolling friction. At the same time, polyurethane has good tolerance to chemicals such as oils, acids, alkalis, and solvents, and shows excellent durability in industrial scenarios.

If you want to produce high-quality polyurethane wheels, please consult UREXCEED polyurethane elastomer PU coating machine. According to different industrial needs, our equipment can be customized for specific products and applications. For example, special equipment for high-hardness elastomers or soft elastomers.

If you want to make other

Mining Products

If the applications above can't meet your requirements, we can supply customized pu foam machine solution for your products making.

For Mining Industry

Related PU Machines

Customers' Feedback of

PU machine for Mining

Company is made up of a group of highly skilled gardening landscaping professionals and who pays a lot of attention the small details. In the years of experience our staff keep your looking and functioning beautifully.

Company is made up of a group of highly skilled gardening landscaping professionals and who pays a lot of attention the small details. In the years of experience our staff keep your looking and functioning beautifully.

Latest News

Of Our PU Foam Machines

How to Deal with Excess Foam Bubbles in Refrigerator Production

During refrigerator manufacturing, the quality of the foam layer is directly related to thermal insulation performance and product stability. Improper control of the foaming time often results in excessive bubbles in the foam layer, bulging on the back, or localized overflow. These issues are largely due to poor internal structural design and production process control […]

Common causes and solutions for refrigerator molds with incomplete foaming and insufficient corner filling

If the corners of the refrigerator back panel or inner tank mold are not filled enough or the local foaming is not full during the polyurethane foaming process, it will not only affect the thermal insulation performance of the product, but may also lead to scrapping or rework. The following are common causes of such […]

Is the defective foaming rate of refrigerators increasing?

In the refrigerator production process, the quality of polyurethane foaming is directly related to the thermal insulation performance and energy level of the product. When problems such as poor foaming, uneven foam structure or insufficient filling occur, they are often caused by omissions in process control or equipment parameters. In response to this challenge, the […]

Other Industries Our Polyurethane Machines Serve

There are many other industries that our pu foam making machines can be applied to make polyurethane products.