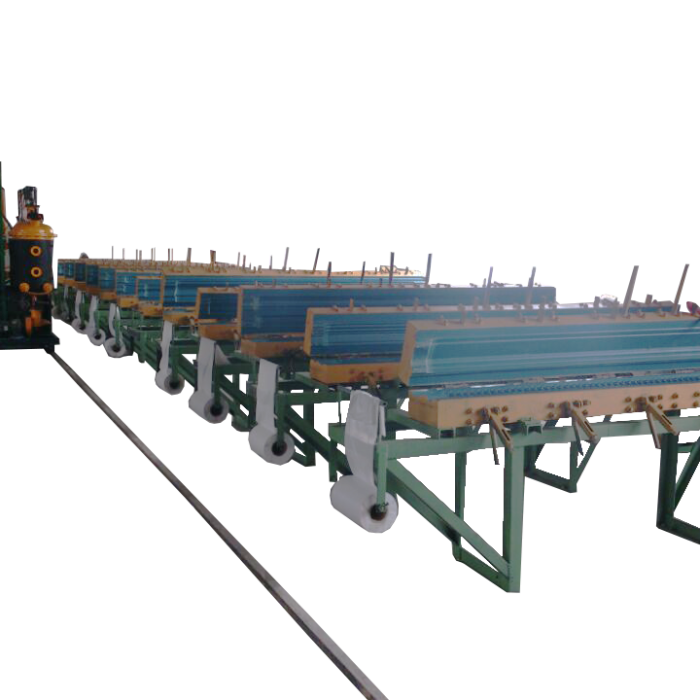

PU Crown Moulding Production Line

UREXCEED® polyurethane cornice moulding production line is an efficient, automated system for producing high-quality, customizable decorative products. It meets the growing demand for durable, lightweight materials in construction and home decoration.

PU Cornice Production Line

UREXCEED®polyurethane crown moulding production line is a highly efficient system designed for the production of polyurethane decorative mouldings, wall panels, window sills, and other architectural materials. This production line utilizes advanced polyurethane foaming technology, combined with high-precision moulds and an automated control system, ensuring the accurate forming and foaming of mouldings in various shapes and sizes. With optimal formulations and process control, polyurethane cornice mouldings exhibit excellent properties such as lightweight, strength, abrasion resistance, and weather resistance, making them widely used in interior and exterior decoration and home furnishings.

UREXCEED® equipment in the production line includes a raw material batching system, foaming and mixing system, moulding dies, and automated packaging system. The entire production process is fully automated, ensuring stable product quality and enhanced production efficiency. Additionally, the polyurethane cornice moulding line supports customized production, offering different specifications and densities based on customer requirements to meet the demand for personalized and diverse decorative materials in the market.

Main Equipment Of PU Cornice Production Line

PU Cornice Mold

The high-pressure machine efficiently injects raw materials into moulds using advanced mixing technology, ensuring precise, consistent foaming and optimal production efficiency.

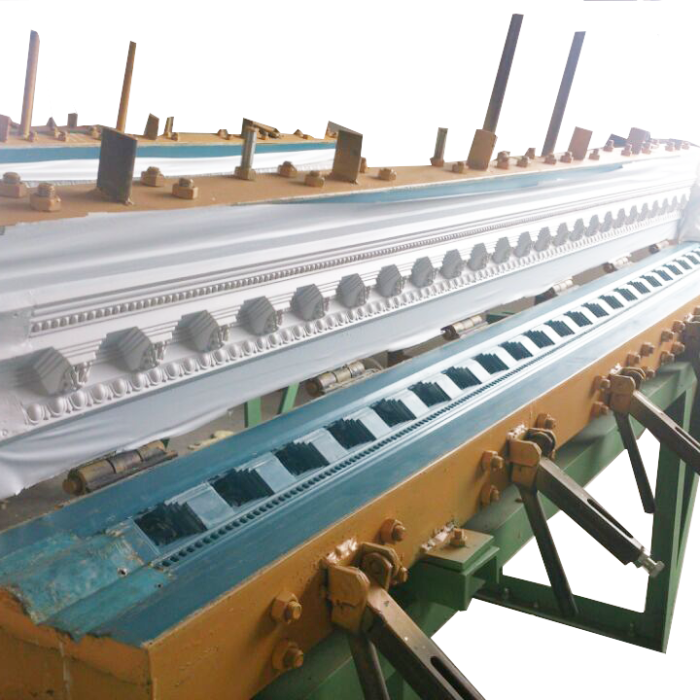

PU Cornice Mold

The high-pressure machine efficiently injects raw materials into moulds using advanced mixing technology, ensuring precise, consistent foaming and optimal production efficiency.

High Pressure Foam Machine

The mould is designed for precise shaping of PU cornices, featuring high-quality materials and PVC film for smooth, textured finishes and easy demoulding.

High Pressure Foam Machine

The mould is designed for precise shaping of PU cornices, featuring high-quality materials and PVC film for smooth, textured finishes and easy demoulding.

Trimming Machine

The trimming machine accurately cuts and shapes finished cornices, ensuring smooth edges and enhancing production efficiency with automatic feeding and high-speed operation.

Trimming Machine

The trimming machine accurately cuts and shapes finished cornices, ensuring smooth edges and enhancing production efficiency with automatic feeding and high-speed operation.

Production Process Of PU Cornice Production Line

Step 1: Raw Material Preparation

The process begins with the precise formulation and thorough mixing of polyurethane raw materials, ensuring uniformity across all components. The quality of the raw materials is crucial to the foaming effect and strength of the final product, so we strictly control the formulation and mixing process for each batch.

Step 2: High-Pressure Injection

Step 3: Moulding Process

After the materials are injected, they begin foaming and take the shape of the mould. The moulds are made from high-quality materials to ensure the cornices are accurately sized and shaped. The use of PVC film not only enhances the aesthetic texture of the surface but also prevents material from sticking to the mould, improving the demoulding process.

Step 4: Demoulding

Once foaming is complete, the moulded cornices are carefully removed from the moulds. Thanks to the design of the moulds and PVC film, the demoulding process is smooth, ensuring the cornices remain intact and undamaged.

Step 5: Trimming and Shaping

Finally, the moulded cornices are processed by the trimming machine to achieve precise dimensions and smooth edges. The high-precision cutting capabilities of the trimming machine ensure that each cornice meets the required specifications and has a consistent, polished appearance.

If you want to know more about pu cornice moulding production line , feel free to contact us

Playlist

Good Review Of UREXCEED PU Cornice Production Line

PU crown moulding production line UREXCEED® has earned widespread acclaim from customers worldwide for its efficiency, precision, and high-quality results. Clients appreciate its seamless operation, customizable features, and ability to deliver consistent, top-notch decorative cornices tailored to their needs.

We’ve been using this production line for over six months, and the results are outstanding. The automated process saves time, and the moulds produce flawless cornices with beautiful textures. A great investment for our business!

Sophia AustraliaThe quality and consistency of the PU cornices produced are unmatched. The line is user-friendly, and the support team provided excellent training and after-sales service. Highly recommended!

Ahmed United Arab EmiratesThis production line delivers exceptional efficiency and customization options. We were able to meet unique customer requests without compromising quality. Truly a game-changer for our factory!

Emma Germany

The PU Cornice Production Line has completely transformed our production process. The high-pressure machine ensures precise and efficient material injection, and the trimming machine delivers perfect finishing every time. It’s a reliable solution that meets all our expectations.

Carlos R. Chile