Introduction

As the global push for energy efficiency and sustainability accelerates, the refrigeration industry is undergoing a dramatic transformation. Central to this evolution is a quiet hero: polyurethane (PU) insulation.

Used in refrigerators, freezers, and commercial cold chain systems, polyurethane foam is the industry’s top choice for thermal insulation. Its exceptional low thermal conductivity, structural strength, and process adaptability are fueling the next wave of high-performance cooling appliances — from energy-efficient home refrigerators to AI-driven smart cooling systems.

In this article, we’ll explore the latest trends in both the refrigeration industry and polyurethane technology, highlight their intersection, and explain why PU foam and equipment are critical to the future of sustainable cooling.

Global Refrigeration Market Outlook

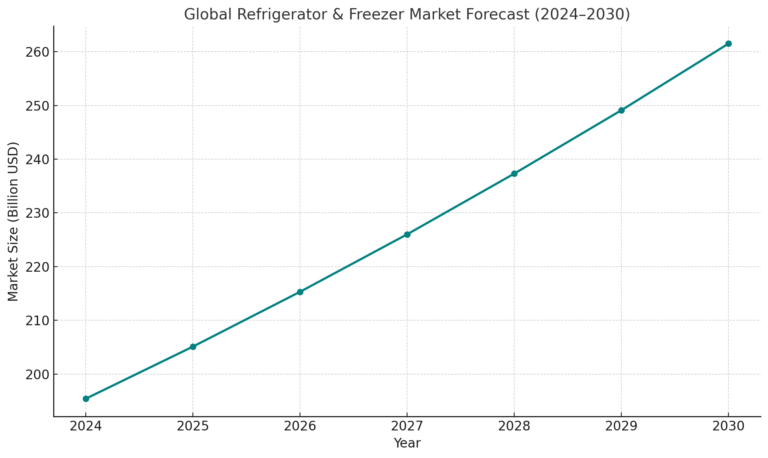

The global refrigerator and freezer market is forecast to reach $195.4 billion by 2024, with an expected CAGR of 5–6% through 2030. Key growth drivers include:

Rising demand for energy-efficient appliances

Expansion of cold chain logistics in developing regions

Growth in smart home ecosystems

Regulatory shifts in energy labeling and refrigerant standards

Meanwhile, the global polyurethane market is also booming. Estimated at $87 billion in 2023, it’s projected to exceed $113 billion by 2030, driven by demand in appliance insulation, automotive, and construction.

These parallel trends point to an industry convergence: Refrigeration is increasingly relying on PU insulation systems to meet performance, regulatory, and sustainability goals.

Why Polyurethane Foam Is the #1 Choice for Refrigerator Insulation

Polyurethane rigid foam (PUF) is the preferred insulation material for domestic refrigerators, freezers, and commercial units for several reasons:

✅ Superior Thermal Insulation

PU foam’s low thermal conductivity (as low as 0.021 W/m·K) minimizes heat transfer, enabling A++ or A+++ energy ratings.

Closed-cell structure offers excellent vapor resistance, keeping internal cooling efficient.

✅ Space-Saving Design

PU foam allows for thin wall insulation without sacrificing R-value, enabling larger internal volume.

Compared to vacuum panels (VIPs), PU remains cost-effective and easier to process.

✅ Structural and Mechanical Strength

Acts as both an insulator and structural support, resisting compression, transport, and long-term use.

Excellent dimensional stability even under cyclic thermal loads.

✅ Adaptable to Smart Manufacturing

PU insulation is highly compatible with automated foam injection systems, AI-controlled dosing, and cyclopentane-based foaming for eco-friendly production.

Equipment & Chemical Innovation: Driving Efficiency in PU-Based Refrigeration

🧪 Advanced Raw Materials

Use of low-VOC blowing agents, bio-based polyols, and high-reactivity MDI/TDI improves foam performance while meeting international environmental standards.

Fire-retardant additives (e.g. phosphate esters, amine catalysts) enhance safety and durability.

🏭 Next-Gen PU Foaming Equipment

Manufacturers like SAIP, Pluskim, FSI, Kimpur, Urexceed and BASF are offering:

Closed-loop metering systems for precise chemical dosing

High-pressure injection heads for fast cycle times and better foam uniformity

Fully automated PU insulation lines that support Industry 4.0 smart factories

Real-time temperature and density control systems

These systems allow refrigerator makers to optimize insulation thickness, reduce waste, and improve energy performance.

Applications Across the Cold Chain Ecosystem

Polyurethane’s versatility makes it ideal for a wide range of refrigeration applications:

| Application | PU Benefit |

|---|---|

| Household Refrigerators | High insulation + thin walls = energy + space gains |

| Deep Freezers | Extreme thermal resistance and long life span |

| Commercial Cold Storage | Scalable insulation panels and equipment integration |

| Smart Cooling Systems | AI-optimized PU dosing improves energy usage |

| Transport Coolers | Light weight + structural integrity |

Comparison: PU Foam vs VIP Panels

| Feature | Polyurethane Foam | Vacuum Insulated Panels (VIP) |

|---|---|---|

| Cost | Low | High |

| Thermal Value | Excellent (0.021–0.025 W/m·K) | Superior (but fragile) |

| Durability | High | Susceptible to puncture |

| Recyclability | Improving (bio polyols rising) | Limited |

| Ease of Use | Fast-curing, automated | Complex to install |

Conclusion: The Future Is PU-Fueled

As sustainability, energy efficiency, and smart manufacturing reshape the cooling industry, polyurethane foam stands out as the most versatile and high-performance insulation material.

From household fridges to industrial chillers, PU insulation systems deliver unmatched thermal efficiency, manufacturing scalability, and design flexibility. Coupled with next-gen foaming equipment and greener raw materials, polyurethane is powering a cooler, smarter, and more energy-conscious future.

Launch Your Refrigerator Business with Expert Support — Custom Solutions for Global Markets

Looking to enter the refrigerator industry but not sure where to begin? We are a trusted provider of refrigerator project solutions, offering full-service support for entrepreneurs, investors, and OEM/ODM businesses.

✅ What We Offer:

Turnkey refrigerator project setup

Customized plans based on your budget and target country

Factory design and production line setup

Refrigerator design, R&D, and branding

Market testing with ready-made products (low-risk entry)

Sales and distribution strategy support

Whether you’re just getting started or scaling an existing business, we help clients go from concept to commercial success.

Even with a limited budget or market uncertainty, we offer flexible options:

We can co-invest, provide local product launch, and test hot-selling models in your region — all designed to validate demand and minimize your risk.

💡 Why Choose Us?

10+ years of experience in refrigerator manufacturing solutions

Proven success in Asia, Africa, the Middle East, and Latin America

In-depth knowledge of global energy standards and compliance

Custom OEM/ODM capabilities for branded appliances

📩 Start your refrigerator business today — contact us for a tailored proposal.