PU Machines Manufacturing on Demand for the Toys Industry

The toy industry is a global market, covering a wide range of fields from traditional toys to intelligent and electronic toys. Polyurethane materials have the advantages of lightness, durability, good plasticity, and strong environmental protection, so they are widely used in many fields of toy production (such as toy shells, fillings, soft toys, etc.).

UREXCEED mainly focuses on some stress foam toys and toy fillings in the toy industry. We are deeply involved in the stress ball market and have many customers in Southeast Asia and Europe. In addition to toy ball molds and high-pressure foaming machines, we can also provide a complete set of supporting equipment such as toy ball transfer films and transfer film cutting machines. So if you have any needs in this regard, please contact us.

The Prospects of Polyurethane in the Toys Industry

In order to better understand the application prospects of polyurethane in the toy industry, we can conduct data analysis from aspects such as market size, growth rate, and competitive landscape, and comprehensively evaluate the market potential of polyurethane based on actual market trends and consumer demand.

The Distribution of Different Insulation Materials in the Toy Industry

Property | Polyurethane (PU) | PVC (Polyvinyl Chloride) | Rubber | EVA (Ethylene-Vinyl Acetate) | ABS (Acrylonitrile Butadiene Styrene) | Wood |

Density (g/cm³) | 1.1 – 1.3 | 1.3 – 1.4 | 1.1 – 1.4 | 0.92 – 1.0 | 1.04 – 1.1 | 0.5 – 0.9 |

Tensile Strength (MPa) | 30 – 60 | 30 – 60 | 10 – 30 | 10 – 30 | 40 – 60 | 40 – 100 |

Elongation at Break (%) | 300 – 800% | 150 – 400% | 100 – 400% | 100 – 400% | 5 – 10% | 10 – 20% |

Hardness (Shore A) | 60 – 95 | 60 – 85 | 40 – 70 | 40 – 80 | 80 – 95 | 30 – 80 |

Abrasion Resistance | High | Moderate to high | Excellent | Good | High | Low |

Impact Resistance | High | Moderate | High | Moderate | High | Moderate |

Water Resistance | Excellent | Poor | Good | Excellent | Poor | Moderate to high |

Chemical Resistance | Good, resistant to oils, solvents | Moderate to good | Low | Moderate to good | High | Low |

Flexibility | High | Moderate | High | High | Moderate | Low |

Temperature Resistance | -40°C to 80°C | -10°C to 60°C | -40°C to 120°C | -30°C to 80°C | -20°C to 100°C | -20°C to 80°C |

Shock Absorption | Excellent, soft and cushioned | Moderate | Excellent | Good | Moderate | Low |

Recyclability | Low | Moderate (limited) | High | High | High | High |

Cost | Moderate to high | Low to moderate | Low | Low to moderate | Moderate to high | Moderate to high |

Applications in Toys | Soft toys, foam toys, squishy toys | Figurines, inflatable toys, teething toys | Rubber toys, bouncy balls | Foam toys, soft educational toys | Action figures, toy vehicles | Educational toys, puzzles, building blocks |

Advantages Of UREXCEED In The Toy Industry

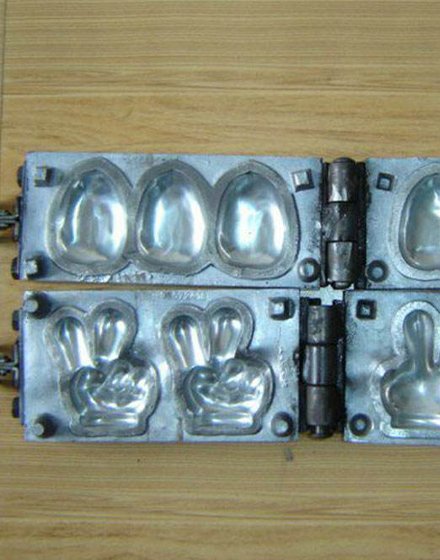

We have a professional team and advanced equipment to meet customers' different needs. Our polyurethane molds are made of high-quality materials to ensure stable product quality and strong durability. We can also design molds of different shapes and sizes according to customer requirements to meet the production needs of different products.

In addition to mold design and manufacturing, we also provide design and manufacturing services for PU machinery and production lines. With our rich experience, we can help customers improve production efficiency, reduce costs, and enhance product quality. Our machines and production lines use advanced technology, are easy to operate, and easy to maintain.

If you are looking for solutions for polyurethane molds, machinery, and production lines in the toys industry, please contact UREXCEED. We will provide you with high-quality products and services to help you achieve your production goals and increase competitiveness.

Urexceed's partners in the toys industry are diverse and of varying sizes.

No matter you are Children's toy manufacturers, Stress relief toy factories, Rehabilitation training tool manufacturers, Cultural and creative gift companies, Sporting goods stores, Anime peripheral factories, Pet toy manufacturers, Preschool education product suppliers or not, you can contact us for more information of toys Industry.

Polyurethane Foam Injection Machines

For Toys Applications

Stuffed Toys Polyurethane Foam Injection Machine Customized

Polyurethane foam is often used as the internal filling material for plush and stuffed toys, providing softness and shape retention. Its low density and high resilience ensure that the toys remain comfortable to the touch and have good compression resistance, and will not deform even after repeated squeezing and use.

Both our high-pressure and low-pressure machines can be used to stuff toys. The specific machine to choose depends on the customer’s budget and production. No matter what toys you need to stuff, we can provide you with a customized solution.

Polyurethane Foam Simulation Model Customize Molding Machine

Polyurethane foam material is often used to make various simulation model toys, such as animal models, role models, etc. Its light and strong characteristics make the toys have both simulated visual effects and convenient for children and adults to carry and operate.

If you also need to make a simulation model, you are welcome to use our foaming machine. You can send us the detailed parameters of your product and we will provide you with a detailed plan and budget.

Customized Polyurethane Flexible Foam Toys Manufacturing Solution

Polyurethane materials have good flexibility and can be used to make various deformable flexible toys, such as soft balls, decompression toys, etc. These toys can withstand repeated squeezing and are not easily damaged, and are loved by children and adults. For example, the smile ball is very popular among people in Southeast Asia.

Our polyurethane machines are popular with toy manufacturers, but in addition to large-scale toy manufacturers, our polyurethane foaming machines can quickly adjust parameters and are also suitable for producing small batches of customized toys, such as corporate gifts or limited edition toys.

If you want to make other Toys

If the applications above can't meet your requirements, we can supply customized pu foam machine solution for your products making.

Toys Manufacturing

With PU Foam Molding Machines

Customers' Feedback of

PU machine for Toys

Company is made up of a group of highly skilled gardening landscaping professionals and who pays a lot of attention the small details. In the years of experience our staff keep your looking and functioning beautifully.

Company is made up of a group of highly skilled gardening landscaping professionals and who pays a lot of attention the small details. In the years of experience our staff keep your looking and functioning beautifully.

Latest News

Of Our PU Foam Machines

How to Deal with Excess Foam Bubbles in Refrigerator Production

During refrigerator manufacturing, the quality of the foam layer is directly related to thermal insulation performance and product stability. Improper control of the foaming time often results in excessive bubbles in the foam layer, bulging on the back, or localized overflow. These issues are largely due to poor internal structural design and production process control […]

Common causes and solutions for refrigerator molds with incomplete foaming and insufficient corner filling

If the corners of the refrigerator back panel or inner tank mold are not filled enough or the local foaming is not full during the polyurethane foaming process, it will not only affect the thermal insulation performance of the product, but may also lead to scrapping or rework. The following are common causes of such […]

Is the defective foaming rate of refrigerators increasing?

In the refrigerator production process, the quality of polyurethane foaming is directly related to the thermal insulation performance and energy level of the product. When problems such as poor foaming, uneven foam structure or insufficient filling occur, they are often caused by omissions in process control or equipment parameters. In response to this challenge, the […]

Other Industries Our Polyurethane Machines Serve

There are many other industries that our pu foam making machines can be applied to make polyurethane products.