Rigid polyurethane foam(RPUF) is one of the most versatile and widely used materials in various industries due to its exceptional properties, such as excellent thermal insulation, lightweight, and high strength. It is a closed-cell foam that is lightweight yet highly durable and efficient at reducing heat transfer. RPUF has become essential in a variety of applications, from construction and refrigeration to automotive and packaging. In this article, we’ll explore the most important applications of rigid polyurethane foam and how it plays a key role in modern industry.

Building and Construction

Rigid polyurethane foam is a critical material in the construction industry, especially when it comes to energy-efficient buildings. It is primarily used for thermal insulation in walls, roofs, and floors, helping to maintain the internal temperature of buildings. This application helps reduce heating and cooling costs and contributes to energy savings.

- Exterior Insulation: Used in the form of panels or spray foam to insulate the exterior of buildings.

- Roof Insulation: Applied to roofs, especially flat roofs, for effective thermal control.

- Floor Insulation: Used beneath floors to reduce heat loss to the ground.

RPUF’s ability to provide excellent thermal performance with a minimal thickness makes it an ideal choice for energy-efficient and eco-friendly buildings, including passive houses and green buildings.

Refrigeration and Cold Chain Logistics

Rigid polyurethane foam plays a crucial role in the refrigeration industry. Its superior insulation properties make it ideal for maintaining a consistent temperature in both commercial and residential refrigerators, freezers, and cold storage facilities.

- Refrigerator and Freezer Insulation: Used in the production of refrigerators, freezers, and ice cream storage units, where temperature control is critical.

- Cold Storage Units: Insulated panels made of rigid polyurethane foam are used to build walls, ceilings, and floors of cold rooms and warehouses, maintaining the required low temperatures for perishable goods.

- Cold Chain Transportation: Used in refrigerated trucks, containers, and shipping boxes to ensure that food, pharmaceuticals, and other temperature-sensitive goods remain at the desired temperature during transit.

The foam helps reduce energy consumption and ensures the safe transport of perishable items by maintaining temperature stability.

Automotive Industry

Rigid polyurethane foam is used extensively in the automotive industry, particularly in the production of lightweight, energy-efficient components. It is used to make insulation materials and structural components that enhance vehicle performance.

- Seat Cushions: RPUF is widely used in automotive seat cushions for its comfort, durability, and lightweight properties.

- Interior Insulation: Used in car doors, roofs, and dashboards to reduce road noise and vibrations.

- Energy Absorption: Used in bumpers and impact zones of vehicles to absorb energy in the event of a crash.

- Lightweight Components: Rigid polyurethane foam is used in panels and structural components, reducing overall vehicle weight and improving fuel efficiency.

The use of RPUF in the automotive industry not only enhances vehicle safety but also contributes to environmental sustainability by improving fuel efficiency and reducing emissions.

Packaging Industry

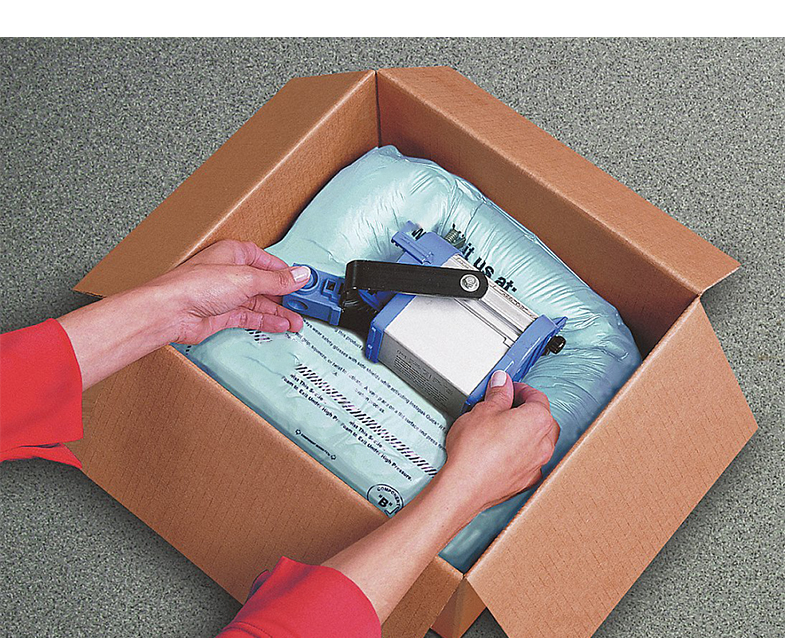

Rigid polyurethane foam is a key material in the protective packaging industry. Its shock-absorbing properties make it ideal for packaging sensitive electronic goods, machinery, and high-end products.

- Protective Packaging: It is used in packaging materials for fragile items, providing protection against impact during transportation.

- Custom Foam Inserts: Used to create custom foam inserts for delicate equipment, electronics, and medical devices.

- Shipping Containers: Used in the construction of temperature-controlled packaging, where the foam helps maintain a consistent temperature for goods in transit.

RPUF’s ability to provide cushioning, combined with its lightweight nature, makes it ideal for protecting valuable or fragile items during transport.

Marine and Offshore Applications

In the marine and offshore industries, rigid polyurethane foam is used as both a flotation material and for insulation. Its excellent buoyancy properties make it suitable for a variety of marine applications.

- Flotation Devices: Used in the production of life jackets, boats, and offshore platforms, providing buoyancy and stability.

- Ship Insulation: Used in the construction of ships to insulate the hull and reduce the need for energy-intensive cooling systems.

- Offshore Platforms: Used in offshore oil and gas platforms to provide thermal insulation and protect against corrosion.

Rigid polyurethane foam’s durability, water resistance, and lightweight nature make it invaluable for ensuring the safety and energy efficiency of marine and offshore operations.

Energy Sector

In the energy industry, rigid polyurethane foam is applied in various ways to improve energy efficiency and reduce environmental impact.

- Solar Panels: RPUF is used to insulate and protect solar panels, improving their performance and lifespan.

- Wind Turbines: The foam is also used in wind turbine blades, where it helps reduce weight while maintaining strength and durability.

- Energy Storage: Used in the insulation of energy storage devices, such as batteries and fuel cells, to maintain temperature and improve performance.

By providing effective insulation and reducing energy loss, RPUF contributes to the overall efficiency of renewable energy systems.

Aerospace Industry

In the aerospace industry, rigid polyurethane foam is used for thermal insulation in aircraft and spacecraft. Its lightweight nature and high strength-to-weight ratio make it an ideal material for various components.

- Aircraft Insulation: Used to insulate cabins, cargo holds, and other aircraft components to ensure comfort and safety.

- Thermal Protection: Used in spacecraft to protect against extreme temperatures during re-entry into the Earth’s atmosphere.

Rigid polyurethane foam helps reduce the overall weight of aerospace vehicles while ensuring safe temperature regulation.

Rigid polyurethane foam is a versatile material with numerous applications across various industries, including construction, refrigeration, automotive, packaging, marine, energy, aerospace, and healthcare. Its excellent thermal insulation properties, lightweight structure, and high durability make it an invaluable material for modern industrial applications. Whether it’s reducing energy costs, protecting fragile items, or ensuring the safety of transportation, RPUF continues to be an essential part of many high-performance products. As industries evolve and sustainability becomes even more critical, the role of rigid polyurethane foam in driving energy efficiency and reducing environmental impact will only continue to grow.